The venerable “alternative testing” toolkit has been the definitive advanced load testing method of the 21st century.

Elevator safety is crucial for users, authorities and anyone associated with this industry. Smooth elevator operation, along with appropriate testing to demonstrate safety and code compliance, are products of elevator technology, which has seen huge progress in the past few decades. As a consequence, traditional testing methods — such as load testing — are no longer adequate in the 21st century. Today, suitable tools and procedures for alternative testing are available on the market and have been accepted into elevator safety codes.

A quarter of a century ago, the German independent inspection and certification body TÜV SÜD developed a digital solution to replace statutory load tests on elevators. In 1992, this ADIASYSTEM testing method was formally approved by the responsible authorities in Germany to equivalently replace all different kinds of load tests stipulated in elevator safety codes. Since that time, the method has permeated testing, not only in Germany, but also in other countries that postulate the periodic load testing of elevators.

The ADIASYSTEM concept consists of proprietary software and specific electronic transducers for measuring safety-relevant physical parameters. Over the years, the method has been continuously developed, from an initial Disk Operating System software to the latest fully compatible Windows version. A number of additional tools and testing features have been integrated in order to meet all major elevator testing procedures. Efforts have focused on replacing statutory load tests, which are required to verify that safety is met, even in worst-case scenarios. For many years, the ADIASYSTEM had been the only method for this purpose; even today, it represents the cutting edge with a track record of millions of applications.

Replacing traditional load tests by an approved “alternative testing” method is much more than just getting rid of the logistic hassle of moving tons of test weights. While old-fashioned load tests mainly provide a pass or fail result, electronic measurements give much more precise information, indicate available safety reserves and specify how findings fit into the stipulated benchmarks of the code. All results can be easily saved on a PC, and, thus, generate contemporary documentation that permits comparison with previous or subsequent tests, etc.

The 2013 version of the harmonized ASME A17.1/CSA B44 code, Chapter 8.6.4.20, permits “alternative testing” as a new option in North America to replace all periodic load testing requirements. The Technical Standards & Safety Authority was the first AHJ to promote “alternative testing” and adopted this new code requirement in Ontario in 2014. Since that time, several elevator contractors started using this option and applying the ADIASYSTEM method in Ontario.

Applications

In general, the A17.1/B44 code specifies “Category 5 Periodic Load Tests” for the following applications:

- Safeties

- Oil buffers

- Driving-machine brakes

- Braking systems, traction and traction limits

The two ADIASYSTEM gauges contained in the “mini set” version of the product (Figure 1) and the appropriate software tools can replace all the aforementioned tests equivalently. The background and theories of the different alternative testing procedures are explained below.

Safeties

Code requirement 8.6.4.20.1 requires that type B safeties shall reliably stop an elevator car with rated load within defined limits. Traditionally, these limits had been defined by minimum and maximum stopping distances (measured on the guide rails). However, the accuracy of a simple tape measure is limited: often, it is hard to determine the exact start of its marks, and the length of the wedges needs to be subtracted. Moreover, the high kinetic energy of the masses of load in car, as well as counterweight, cause a rather low deceleration, which means the counterweight distinctively contributes to stop the car. In this respect, the safety test does not cover a freefall.

The ADIASYSTEM method is based on a different approach. The safety is tripped with the empty car at rated speed. In the case of high-speed elevators, tripping speed can be reduced when full safety engagement is ensured. The low kinetic energy of the empty car induces a substantially higher retardation, and the car comes to an instant stop without any effective rope forces from the counterweight (like in a freefall). The ADILOG standalone accelerometer measures the precise empty car deceleration with a sampling rate of 5,000 Hz. Then, the automatic recording of the stop will be transmitted to the connected PC, displayed in a deceleration-time diagram and analyzed in detail.

By definition of the constant braking forces of type-B safeties, as well as Newton’s basic physical law of motion, the algorithms of the ADIASYSTEM software calculate the corresponding deceleration value of the loaded car. This information is equivalent to the permissible stopping distances of code tables, and it specifies the appropriate benchmark: the required deceleration value shall be between 0.2 and 1 g. This benchmark is applicable for any rated speed.

Safeties may change their initial setting over time due to various circumstances. TÜV SÜD made a large ADIASYSTEM field test in a country in which no modern techniques had been applied. This revealed that every second safety gear was not working correctly. So, many elevators were in operation with a tremendous risk that remains concealed, unless the safeties are activated in case of an emergency. In comparison, statistical figures in Germany, where ADIASYSTEM tests are applied every two years, show a failure rate of only 0.3%. As safeties are the ultimate lifesaving device, the correct function is imperative.

Whenever a safety test fails, an elevator expert can readjust the setting of type-B safeties in compliance with the specification of the producer to make sure that even a fully loaded car is safely coming to a stop or that the stop is not hard enough to endanger its passengers.

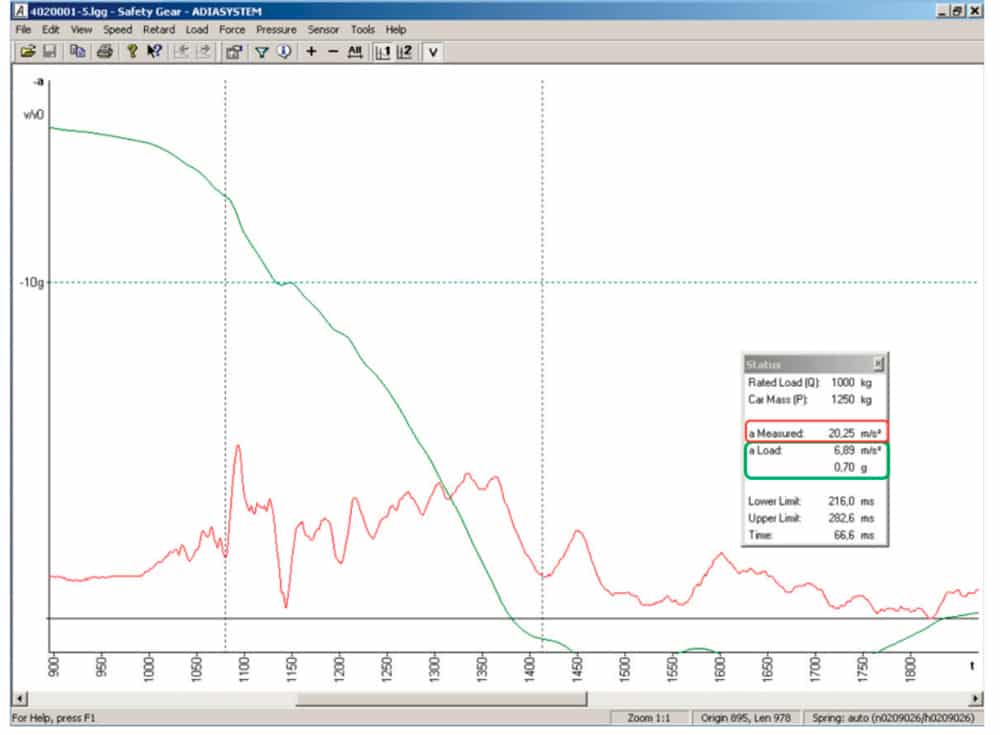

ADIASYSTEM provides detailed information of the stopping behavior of the safeties in a safety-test diagram (Figure 2). The red line represents the measured deceleration versus time, and the green line represents the corresponding velocity change during the stop. The status window shows the essential findings: the deceleration of the empty car in the red frame and the predicted deceleration of the car with rated load in the green frame. The digital documentation cannot be falsified. It clearly demonstrates how safeties were activated and whether they would work correctly for all load configurations, including a freefall condition.

Oil Buffers

For oil buffers, Chapter 8.6.4.20.3 specifies periodic tests with rated load to demonstrate correct damping behavior. In physical terms, this means the required average deceleration of a car with rated load and rated speed is limited to a maximum deceleration of 1 g. In contrast to type-B safeties, oil buffers cannot be readjusted. As a closed system, buffers are rarely affected by external impacts, and as one of the very few failure causes, missing oil will be easily detected. This also means that if visual and functional tests of oil buffers do not indicate defects, recurrent buffer tests with rated load will be identical with previous findings, including the initial commissioning test.

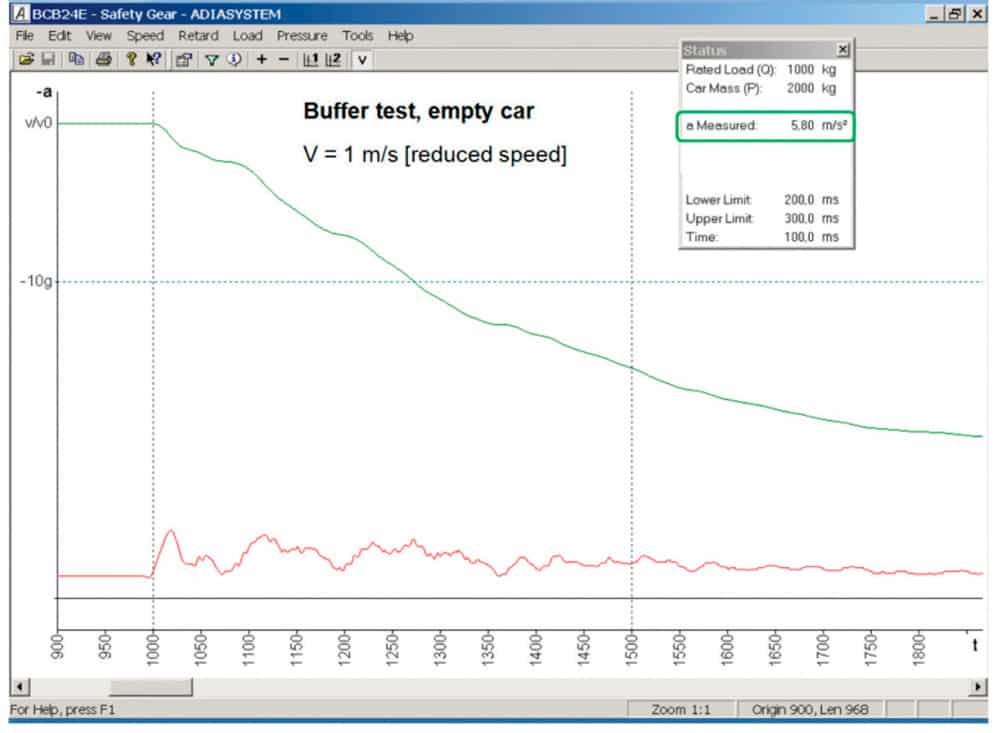

Due to the high amount of kinetic energy, such tests come with a high risk of damaging the elevator or parts, which is not the intention of the test. Therefore, the main purpose of verifying correct buffer performance can be equivalently proved by a less stressful examination, by running the empty car to the buffer at reduced speed. Investigations furnished proof that these tests are very similar to the code-required load tests. As mentioned before, the ADIASYSTEM effectively features the actual deceleration behavior of elevator cars and generates easily interpreted graphic diagrams. Consequently, with the ADIASYSTEM, a less stressful buffer test can demonstrate equivalent findings.

Driving-Machine Brakes

Periodic testing of the driving-machine brake is essential to prevent serious accidents due to the possible hazard of wrong setting or adjustment. The code previously required that the machine brake should safely lower, stop and hold the car with 125% of its rated load. No minimum deceleration was required, but the overloaded car had to come to a full stop.

The new code version in Chapter 8.6.4.20.4 permits any method of verifying conformity of the driving-machine brake, including testing of brakes without a load in the car. Basically, the brake torque is a result of the difference in masses of both sides of the traction sheave. So, the mass ratio of a 125% overloaded car compared to the counterweight is similar to an empty car compared to the counterweight. Of course, in the case of traditional load tests, the total amount of kinetic energy is higher; then, the higher level of inertia causes a longer stopping distance. Furthermore, for typical dual brakes, this test can be conducted while keeping one brake side open, thus separately checking the brake performance twice.

With the ADIASYSTEM, the effective brake deceleration is recorded using one of the two available tools, while running the empty elevator upward at rated speed, then switching off the main disconnect. The average stopping deceleration can be easily determined in a diagram produced from these data. The appropriate benchmarks are specified: a minimum deceleration of ≥ 1 mps² and maximum deceleration of less than 1 g (≤ 9.8 mps²). The minimum requirement of 1 mps² already accommodates the lower level of inertia. An adjustment of the brake is required if the measured actual finding is outside the permissible benchmarks.

Braking Systems, Traction and Traction Limits

Finally, the new Chapter 8.6.4.20.10 specifies requirements for the braking system, traction and traction limits. “Traction” describes the ability to sustain different rope forces on each side of the traction sheave without risk of rope slippage. Similar to the machine-brake standard, the traditional category-5 test requirements stipulated that passenger elevator cars carrying 125% of their rated load shall stop and safely hold the load. Elevator operation causes wear and tear; over time, the initial friction factor changes, and the original traction declines, causing a significant risk of a dangerous accident.

ADIASYSTEM includes a traction test procedure to verify the effectively existing traction of an elevator by measuring the pulling force of a rope. This quantitative determination of the actual traction facilitates the system to go beyond the internationally accepted code criteria of 125% traction, setting its own benchmark at 200%. In fact, more than 98% of all existing elevators in the field meet the more stringent 200% traction criteria. So, ADIASYSTEM tests easily detected the small number of elevators showing a reduced level of traction. With the increase of a large variety of machine-room-less (MRL) units, as well as a number of different new means of suspension, the original traction test procedure became more complex to achieve.

A new ADIASYSTEM traction test procedure has been introduced based on a modified deceleration measurement. The concept of this test had been already described in one of the ADIASYSTEM patents registered in 1990. This test requires a considerably higher level of retardation in comparison to testing the machine brake. It can be achieved by modern gearless motors with magnetic reversal, which generate observable shorter stopping times.

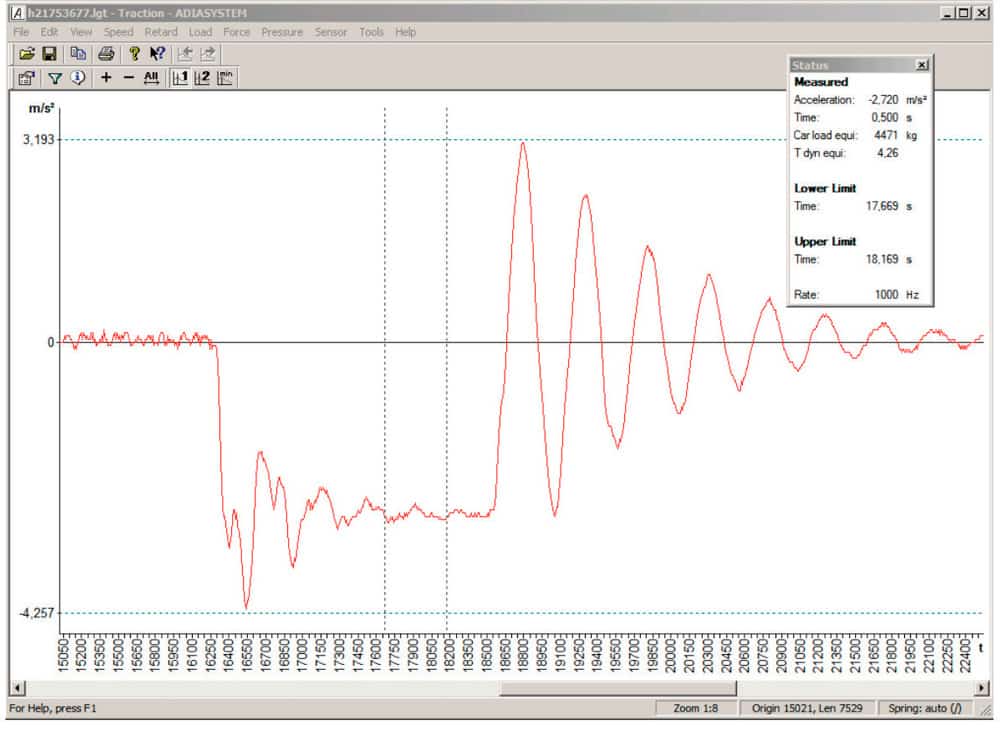

The test is performed by first running the empty elevator up at rated speed. Then, the safety circuit is opened, and the deceleration (aEstop) is recorded and analyzed. Such a short stoppage increases the dynamic weight of the counterweight and causes load removal on the car side. The appropriate differing rope forces permit an equivalent dynamic traction value (Tdyn equi). The measured data provide proper evidence in a respective diagram that the related retardation and, consequently, the equivalent dynamic traction value have been achieved.

Modern MRL elevators with lightweight designs often substantiate high values of Tdyn equi. Thus, neither an exact car mass, nor a counterweight mass needs to be considered. The basic traction benchmark of the code is to achieve at least 125%. However, as traction is based on the effectively existing rope forces, it is obvious the accuracy of masses is to be included. That is why the evaluation guideline stipulates different benchmarks, which are based upon the accuracy of masses. As a consequence, this procedure may not be applicable to all elevators. For such cases, the ADIASYSTEM traction test with rope force measurement remains essential. Thus, this ADIASYSTEM test is another essential verification to quantify an important existing safety parameter and prevent the risk of loss of traction and a worst-case accident.

Conclusion

The elevator industry has conducted traditional load tests to check for mechanical failures of elevators and prevent accidents for more than a century. It is fundamental to continue running such safety-relevant tests on modern elevators. However, more-sophisticated tools and procedures are available to replace the old-fashioned tests by more contemporary methods. Today, any required statutory load test can be replaced equivalently by a no-load method. “Alternative testing,” however, does not just mean saving costs, labor and wear. It also efficiently contributes to the prevention of serious incidents and fatalities.

For a quarter of a century, the application of ADIASYSTEM as a modern testing technique has been imperative to increase elevator safety and prevent life-threatening accidents. At the same time, the worldwide elevator industry also implemented digitalization, useful sensors, condition monitoring and other technology. However, the approach of alternative testing is fundamentally different: elevator experts badly need modern digital tools to measure, evaluate and authenticate crucial safety parameters and generate proper documentation to fully meet all statutory obligations.

Figure 2: Safety-test diagram

Figure 3: Oil-buffer test diagram

Figure 4: Brake test diagram

Figure 5: Traction-test diagram

Get more of Elevator World. Sign up for our free e-newsletter.