An Effective Energy-Saving Elevator

Jul 1, 2016

How growing demand for a power-storage battery for elevators combined with a control system can be met

by K. Takasaki, R. Ootsubo, J. Takeda and S. Nojima

Designers in various industrial areas have been tackling energy-saving and environmentally friendly production, which need urgent attention in realizing a sustainable society. The same goes for elevators, and we have been continuously struggling to propose the best solutions. Among many possible solutions, this article focuses on one in particular — namely, storing the power generated from natural power sources in rechargeable batteries for subsequent use under normal operation. The new energy-saving system introduced in this article has proved to be remarkably effective.

There is a growing demand for the development of energy-saving, environmentally conscious elevators. Typical technologies currently employed for achieving energy savings with low power consumption include improvements in system efficiency, effective use of regenerative power and use of “green energy.” Also in high demand are user-friendly products with enhanced functions for ensuring peace-of-mind and safety, such as elevators able to continue operating even in the event of power failure, whether it be planned or not.

In order to respond to these energy saving challenges and power supply difficulties in the event of a disaster, a battery that temporarily stores electric power to be consumed by an elevator is necessary. Against the backdrop of these circumstances, the market demand for products with storage batteries and elevator control systems combined is expected to increase in the future, thus raising expectations and requests for storage batteries.

Lithium-ion batteries with high energy density are expected to be used as the storage batteries installed in elevators. Such batteries need to have an input/output characteristic high enough to instantly charge/discharge a high level of energy in accordance with the operating pattern of the elevator. Furthermore, because systems without a machine room must have a power-supply unit installed in the hoistway, the lithium-ion battery needs to exhibit high performance, long-term durability and superior operating safety in a small space, as well as in a low-temperature environment.

The Battery

The storage battery employed in an elevator needs an input/output characteristic high enough to instantly charge regenerative power produced during operation of the elevator and instantly discharge required energy while the elevator is in powered operation. In addition, because of the environment in which the elevator is installed, the battery needs to have high reliability, durability and operating safety, as well as superior performance at low temperature. These conditions can be satisfied by a high-performance, high-function lithium-ion Super Charge ion Battery (SCiBTM) developed by Toshiba Elevator and Building Systems Corp. The main features of the SCiB are:

- High safety: The SCiB is resistant to internal short-circuits due to the adoption of new oxide-based material. Thermal runaway is prevented, even if an internal short-circuit should result from, for example, an external force.

- Long service life: Even after repeating 10,000 full charge/discharge operations, the SCiB maintains a capacity retention ratio of 80% or more.

- Low-temperature performance: The SCiB has the capability to sufficiently discharge, even at a temperature of –30 °C.

- A wide range of workable state-of-charge

- High input/output: The SCiB can be charged quickly and is good at instantaneous input/output of a large current.

- Space saving: Compared with other secondary batteries (e.g., nickel-metal hydride batteries), the SCiB has high energy density, which can contribute to a small battery size.

In addition to being suitable for an elevator control system due to these features, SCiB has been adopted in electric vehicles, including electric motorcycles, and is expected to find applications in various other fields.

Outline of the Elevator System

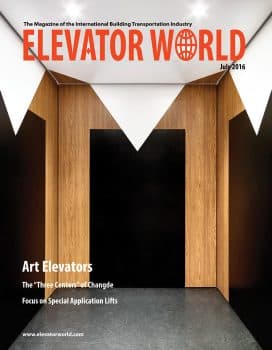

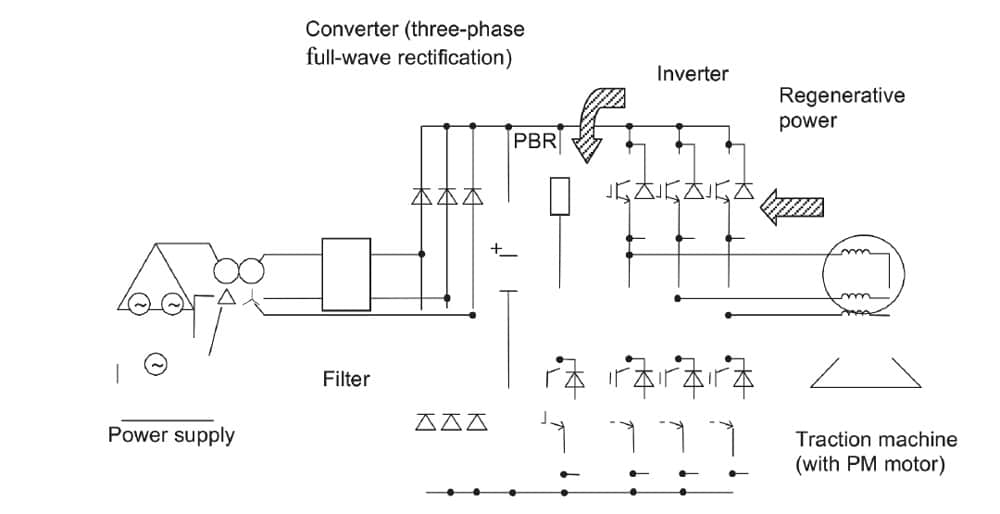

A standard machine-room-less elevator named “SPACEL-GR” using the SCiB is detailed in Table 1. To suppress power consumption, all SPACEL-GR models implement measures such as the use of LED lighting, a standby-power suppression function and enhanced system efficiency. In general, power produced during elevator systems’ regenerative operation is consumed via thermal conversion by a resistor (“PBR” in Figure 1). However, by employing an elevator control system additionally provided with a regenerative power function, such an elevator system can effectively use regenerative power produced during elevator operation by converting it into sine waves via a pulse width modulation (PWM) converter, then feeding those sine waves back to the building.

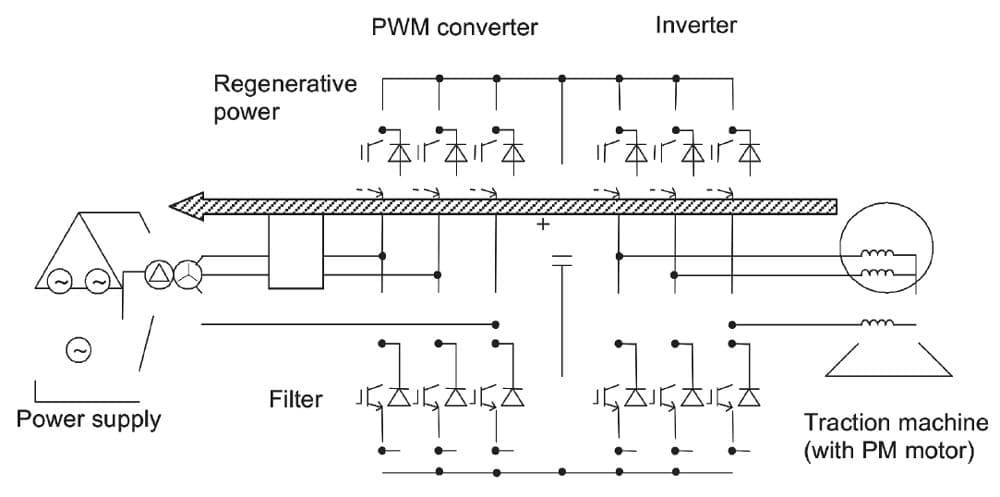

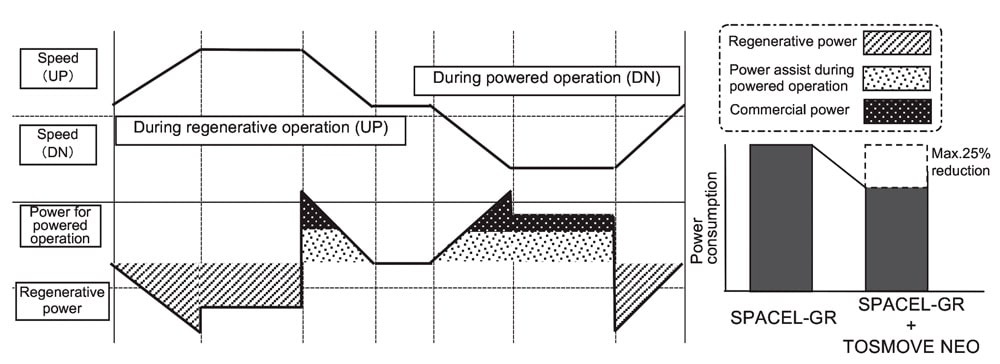

The percentage reduction in power consumption of the SPACEL-GR provided with a regenerative power function relative to a conventional model is displayed in Figure 3, which shows the proportions of the various factors contributing to the reduction. As shown in Figure 3, with the regenerative power function, power consumption can be reduced by a maximum of 50% compared with the conventional model.

Storage Battery Adoption

This section details a product in the form of the SPACEL-GR combined with the SCiB.

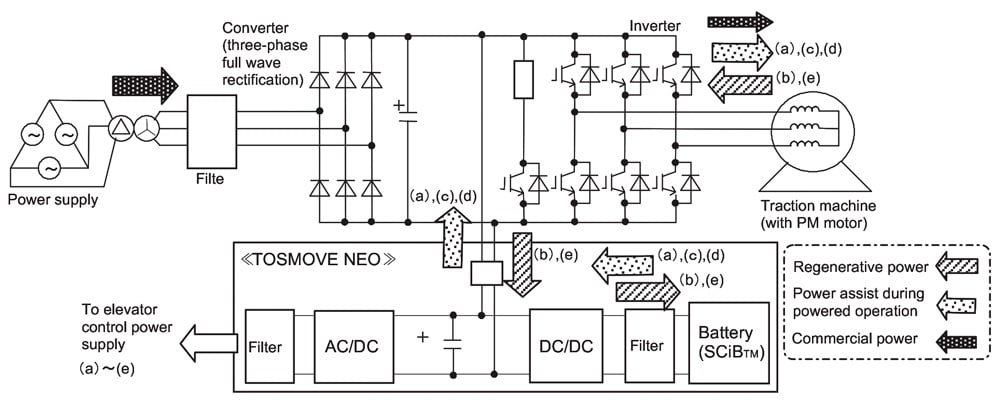

TOSMOVE NEO

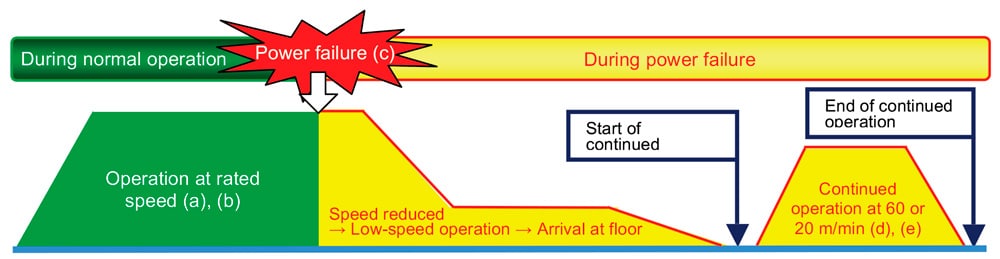

Toshiba’s “TOSMOVE NEO” technology can be added to the SPACEL-GR to allow the elevator to continue operating despite power failure by supplying power from the storage battery to the elevator control system. The TOSMOVE NEO control system and storage battery are both installed in the hoistway. The operating flow of the system from normal operation to power failure is as follows:

- The power consumption suppressing function is enabled during normal operation: the SCiB assists in power output to suppress power consumption.

- During the regenerative-power charge function, the regenerative power is charged into the SCiB.

- When a power failure occurs, the elevator, instead of stopping suddenly or abruptly, gradually reduces its speed and moves to the nearest or desired floor at low speed.

- During continued power failure, the elevator continues moving for a maximum of 30 min. at a speed of 60 mpm or for 120 min. at a speed of 20 mpm.

- While the elevator moves during a power failure, regenerative power is charged into the SCiB as during normal operation.

Storage-Battery System

The storage-battery system that can be added to the SPACEL-GR can also coordinate with a building system. By storing power in the battery during normal operation, the elevator can operate for an extended period at the rated speed, even in the event of power failure. In combination with a photovoltaic power-generation device, this system allows the elevator to operate for an even longer period of time (as long as photovoltaic power is available). Furthermore, it can supply power not only to the elevator, but also to lighting, water-supply pumps, mechanical parking stations, etc.

During normal operation, the battery system can contribute to energy savings of the entire building system by discharging the electric power that has been produced from photovoltaic panels and stored in the battery into the power grid of the building system. Via coordinated operation with the power grid of the building system, the battery system can suppress the maximum electric energy consumed by the building system during normal operation by performing peak reduction and peak shifting of energy in the building system.

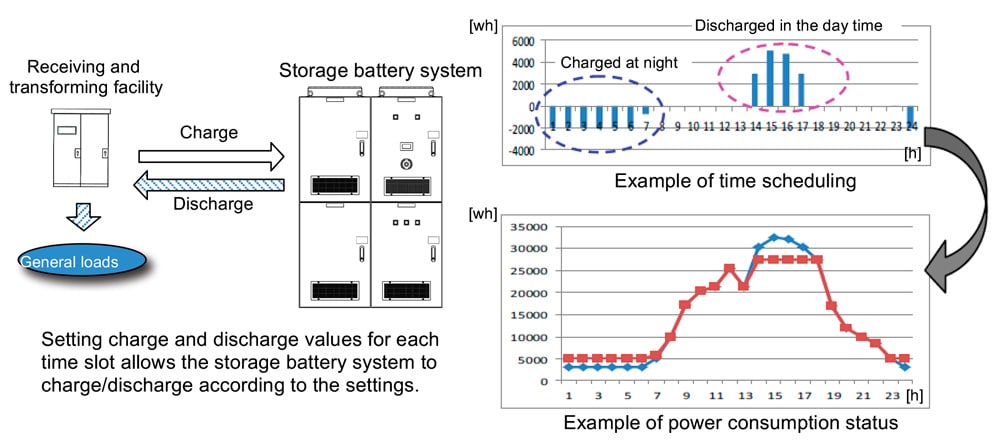

Peak Shifting Function (Scheduled Operation)

The storage-battery system can schedule charging and discharging of the battery during normal operation so as to charge the battery at night, when electric power demands are relatively low, and to discharge the energy in the storage battery to the power grid in the day, when electric power demands are relatively high. In this manner, power consumption in the building system can be reduced in a timeslot when the power consumption in the building system is likely to peak.

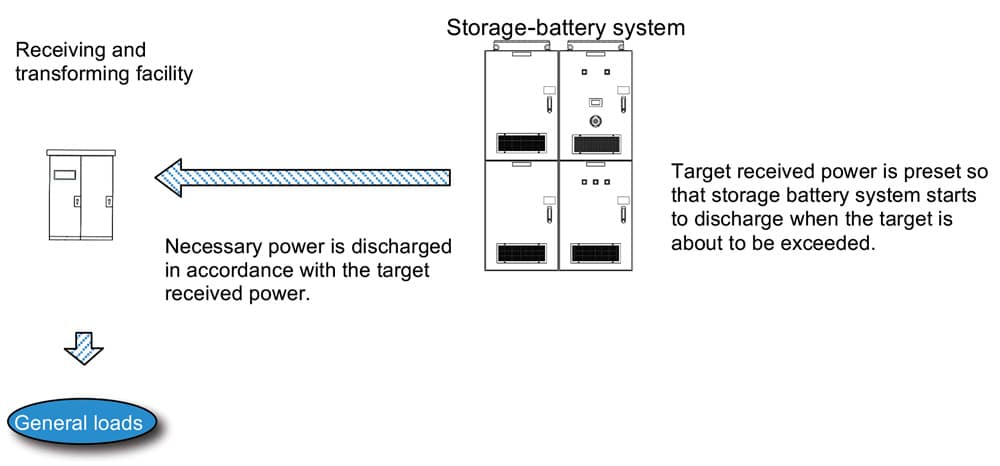

Peak Reduction Function

When the electric energy of the building system is on the verge of reaching the predetermined maximum limit due to a fluctuation in load during normal operation, the battery system can perform peak reduction of the received power in the building system (to avoid purchasing power) by supplying power to the building system so the power consumption in the building does not exceed the target value.

During power failure, the battery system supplies electric power stored in the battery during normal operation to specific loads (single-phase at 100 V/three-phase at 200 V). (A specific load refers to a load system that receives power during power failure, including those in the building system. Typical specific loads are the elevator, lighting devices in common areas of the building, water-supply pumps, mechanical parking stations, etc., and these loads need to be preset as specific loads.) If elevator load has been specified, a battery capacity that allows the elevator to be operated for a maximum of 10 hr. at the rated speed is selected at the time of power failure.

In combination with an elevator provided with a regenerative-power function, the battery system can charge its storage battery with the regenerative power produced during regenerative operation. In this manner, the battery system can continue supplying power for an extended period.

Coordinating with Photovoltaic Power Generation

During normal operation, peak power consumption can be suppressed by using electric power produced by photovoltaic power-generation devices and electric power stored in the storage battery. In charge-prioritized mode, the storage-battery system has a scheduling function that gives priority to charging the battery with power from the photovoltaic devices. When the storage battery is fully charged, the destination of the supplied power is switched to the building system and specific loads. In minimum purchased power mode, the battery system gives priority to the building system and specific loads in supplying power from the photovoltaic devices. Any electric-power surplus remaining after the specific loads have been fully supplied is sent to the battery. This minimizes the amount of power to be purchased for the building system.

During power failure, when the photovoltaic devices are operating, specific loads can be supplied with photovoltaic power, and the storage battery can be charged with surplus power. With this storage battery system applied, energy savings can be achieved not only for the elevator system, but also for the entire building system. Furthermore, a control system with high user convenience can be developed, because power can be supplied without interruption to the entire building system, even during power failure.

Conclusion

In combination with a high-performance, high-function storage battery, this elevator control system achieves significantly reduced power consumption. Furthermore, even in a case where the power supply is interrupted, energy stored in the battery can be supplied to the elevator control system and building system, thus not only allowing the elevator to continue operating for an extended period of time, but also keeping facilities in the building system available. This makes it possible to achieve a product that features both an energy-saving function and user-friendly functions.

Figure 1: General elevator system configuration

Figure 2: Elevator system configuration including a PWM converter

Figure 3: Diagram of power-consumption comparison

Figure 4: Outline of the TOSMOVE NEO control system and storage battery operating pattern

Figure 5: Schematic configuration of the TOSMOVE NEO

Figure 6: The TOSMOVE NEO can reduce power consumption by a maximum of 25% compared with the standard SPACEL-GR

Figure 7: Schematic circuit diagram of the battery system

Figure 8: Schematic of the peak shifting function

Figure 9: Schematic of the peak reduction function

References

[1] Shinichiro Kosugi, Hiroki Inagaki, Norio Takami. “Newly Developed SCiB High-Safety Rechargeable Battery,” Toshiba Review, Vol. 63, No. 2 (2008), p. 54-57.

Get more of Elevator World. Sign up for our free e-newsletter.