Bloomberg London

Jan 1, 2019

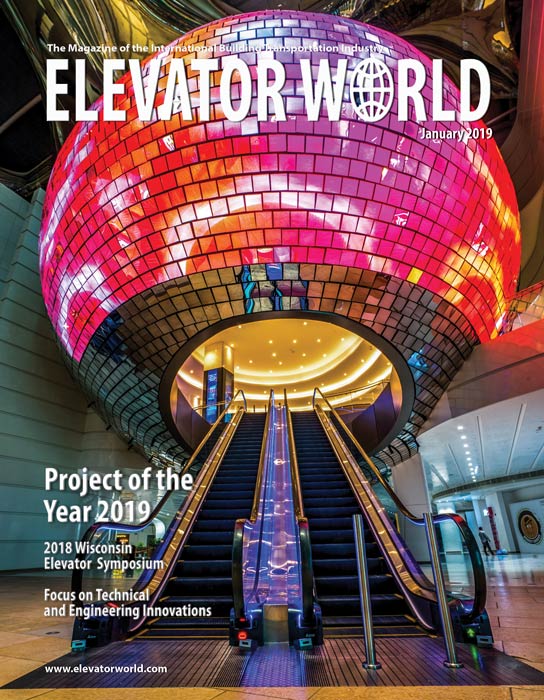

KONE provides showcase pieces to “the most sustainable office development in the world.”

London, England

Financial services giant Bloomberg decided to construct its European headquarters in London, setting out to create a space respectful of the past, present and future. The headquarters occupies an entire city block in the heart of historic London. Its 18 glass elevators are a centerpiece of the collaboration-focused design, giving people a window into a building billed as the most sustainable office development in the world.

Situated on the site of the restored Roman-era Temple of Mithras, Bloomberg London was designed to inspire collaboration among the 4,500-plus employees working onsite, as well as opening up the space to people on the outside. Bloomberg also wanted the building to serve as a working example of sustainable office design, while preserving the rich history of the site.

“The Bloomberg London building is all about looking forward and yet fitting in with the past, which I think is a very challenging thing to achieve architecturally,” says Bloomberg London Project Director Kathryn Mallon, who oversaw the development.

The idea for creating Bloomberg London was sparked in 2010. Architects Foster + Partners worked closely with Michael Bloomberg to bring the vision to life. They designed a two-building structure linked by bridges above three public plazas and a pedestrian arcade. The offices cover a 3.2-acre site that occupies an entire city block.

Bloomberg London is defined by its sandstone frame, covered in bronze fins of varying shapes and sizes. Once inside, visitors pass through a high space called the Vortex, a cavern of curved timber and light. From here, glass elevators take them straight up to the building’s sixth floor and The Pantry, a communal-space concept common to the arrival experience at all Bloomberg offices. This one offers a breathtaking view of St. Paul’s Cathedral and other London landmarks.

Bloomberg London’s open-plan floor concept is designed to promote transparency and collaboration, with meeting rooms and offices also made of glass. Michael Jones, senior partner at Foster + Partners and lead architect for Bloomberg London, explained, “It’s less about a prescriptive way of moving through buildings and more about an intuitive way, one that people can enjoy and prosper from.”

The Elevators

KONE was awarded the contracts to design, develop, deliver and maintain all the elevators for the building, including the 18 unique, scenic lifts, in 2013. This became one of the most ambitious projects ever undertaken by the company. The challenge included creating 360° transparent scenic lifts and lift shafts. Each had to be able to take 2500 kg/33 people at 2 mps. It was important to ensure visibility all the way through the lifts, as they were not to be housed in the core of the building, but moved to the exterior. Jones elaborated:

“Pushing all the core and vertical elements to the outside presented a whole series of different challenges, key to which was delivering a set of elevators that were as clean, transparent and visually permeable as possible. The all-glass scenic KONE elevators are an integral part of the experience, enabling people to see into and out of the building much more fluidly than you can through a typical elevator shaft.”

Advanced Technology

The solutions installed include:

- 18 unique KONE MiniSpace™ scenic elevators

- Six KONE MonoSpace® firefighting elevators

- One Mythras MonoSpace access lift

- Nine service/goods elevators: six KONE TranSys™ and three MonoSpace

These solutions offered reduced waiting time and more efficient user navigation of the building, while improving security and access control. The KONE Destination Control System (DCS) incorporates desired destination floors and the number of waiting passengers to significantly improve elevator efficiency and convenience. This additional information leads to increased handling capacity, shorter journey times, fewer intermediate stops and enhanced passenger comfort. The significantly improved system performance is most evident during intense traffic periods and rush hours, when traditional control systems struggle to cope with the high volume of traffic. With the use of KONE E-Link™, Bloomberg can monitor all elevators from a single location. It provides a real-time overview of equipment status, demand, traffic performance and availability. It also provides a comprehensive set of reports on elevator performance (e.g., number of elevator calls per floor), DCS performance (waiting times and time to destination), alarms, etc.

Testing and Installation

As KONE progressed through the project, it became clear that both the prototype testing and installation methods would be like nothing it had undertaken before. For KONE Senior Project Manager Chris Edwards:

“The most unusual part of this job was related to the design of the 33-person elevators themselves, where we have what is known as an unbalanced ‘rucksack arrangement’. Here — against all the principles of statically balanced cars required to meet ride comfort criteria — the elevator car is hoisted solely by a sling attached to the rear of the 4,600-kg car!”

With a fully factory-built glass car weighing 4,600 kg and a slingclad in anodized aluminum weighing 2,600 kg, it was always going to be a challenge to ship them from Hyvinkää, Finland, to London without damaging either. Add to that the challenge of a counterweight weighing 1,800 kg when empty and clad on three sides with bronze. All of this, with a capacity of 33 people (2500 kg) results in a total moving car mass of 9,700 kg.

Transporting the fully completed car lying on one side added its own complications, as many of the components required additional support, since they were no longer in the vertical plane. To be sure of successfully shipping the cars, they were packed, loaded and driven within Finland to ensure they would survive the journey. Involved in the theoretical methods of transportation and installation of each element were the U.K. design and installation teams, specialist transportation and lifting contractors, along with the designers and engineers from Hyvinkää and KONE’s own Global Installation Team. When everybody was happy with the theory, the entire U.K. team was flown to Finland to undergo extensive training on every aspect of the installation with their Finnish counterparts. It was also decided to make the car the very last component to be installed to reduce the risk of damage.

Due to shaft width restrictions, it was necessary to install each car, still lying on one side, into the center of each three-car group shaft, stand it up, lift it and lower it onto the adjacent sling. The car and sling assembly could then be driven under test to Level 2, allowing room for the next car to be installed. This involved some complex rigging arrangements for the temporary lifting equipment. It was necessary to have a 3/4-full counterweight at the top of the shaft, the sling at the bottom, and the installation fully roped and running. It was essential to load the counterweight to enable the machine to run when the car was installed. For safety, the counterweight was supported by steel chains and rope brakes to ensure it would not move as the team worked below the suspended load.

Thanks to extensive testing and product development, including the construction of a three-stop, life-sized prototype, the special arrangement offers a smooth ride, while hiding all the necessary technology under the floor of the elevator car. This allows an unobscured view through the entire glass elevator bank. “All the door gears, air-conditioning and Wi-Fi needed to be underneath the car, whereas they would normally be on top,” said Edwards. Due to the nature of the unusual requirements, only a handful of standard elevator features could be used.

Most scenic elevators have car-operating panels and a sling that interrupt the clear view out of the side of the elevator and across into adjacent shafts. This was very much against the architectural aspirations. The use of a rucksack arrangement took care of the sling obstruction, and the use of destination control significantly reduced the controls needed by the general user enough for the controls to be relocated into the door frames. A service pendant that is plugged into a hidden socket provides service technician’s operation. The same approach was taken for the cartop controller. The roofs of these cars are double-laminated glass, so essential features like emergency stops are in the door frames, with other controls provided by the pendant.

Key benefits to the client are that the elevators allow natural light throughout. Staff enter on the ground and are transported straight to the sixth floor (to The Pantry for socializing) before moving to their working areas.

Challenges

Challenges faced in creating these innovative lifts were considerable. Not only was the flow of people through the building hugely different from that of other office buildings, the design challenge from Foster + Partners was for the elevator cars to be constructed entirely from glass, with no essential equipment visible from the outside or inside. Other solutions included the

building’s firefighting and goods delivery elevators, as well as an elevator taking visitors to the Temple of Mithras, where the elevators open on adjacent walls. Add to this the requirements around top ride comfort, the counterweights needing to be clad in bronze to match the façade and the unusual rucksack arrangement. Additionally, the doors needed to have custom bottom drive doors made from bombproof glass.

Locating the best glass supplier and other partners was not easy. For example, the glass walls to the car are made from triple-laminated glass with fritted interlayers. They are over 5 m tall and 2.2 m wide and weigh up to 620 kg each. To deliver the clean lines demanded, the handrail is mounted directly to disks laminated into the middle layer of the glass. Several materials and finishes were tested before getting an acceptable solution able to withstand the test forces required for the handrail to meet code requirements.

Ride Quality

The design requirement was to meet horizontal and vertical vibration level of better than 10 mg and in-car noise under 52 dB(A). All requirements, including those around noise, vibration control and acceleration/deceleration were proven to be achievable in the test-tower installation then delivered across 18 lifts on site.

BREEAM

The development has undergone a preliminary assessment under the Building Research Establishment Environmental Assessment Method (BREEAM) New Construction Non-Domestic Buildings, which indicates that the building should, subject to all credits being achieved, achieve an “Excellent” rating.

LEED

The North Building has undergone a preliminary assessment under Leadership in Energy and Environmental Design (LEED®), which has indicated the development, subject to credits being

achieved, will obtain a “Platinum” rating. The South Building, subject to all credits being achieved, will obtain a “Gold” rating with an aspiration to achieve “Platinum.”

Conclusion

In October 2018, the Bloomberg development, as “one of the most environmentally friendly office buildings ever conceived,” was awarded the Royal Institute of British Architects Stirling Prize for excellence in architecture. Institute President Ben Derbyshire said the building has “not just raised the bar for office design and city planning but smashed the ceiling.”

Mallon summed up:

“These glass lifts are my favorite part of the building. I love them. I love that they had never been done before. I love that the KONE engineers decided to take that on as a challenge and decided to innovate and create something different, and partnered with us. They embraced the spirit of the project, which was to create new boundaries, whether it be in architecture or engineering.”

Credits

Elevators: KONE plc — Great Britain Building owner: Bloomberg Developer: Stanhope

Architect: Foster + Partners

Main contractor: SRM Consultant: SWECO

Get more of Elevator World. Sign up for our free e-newsletter.