Elevator safety and maintenance in India are discussed in this Readers’ Platform.

Earlier this year, it was widely reported that elevator OEMs and multinational companies in India were pushing for a single piece of nationwide legislation setting minimum standards and specifications. In my view, this is a key requirement that should be addressed now. Currently, we have a “patchwork quilt” situation in which some states are highly progressive with their elevator and escalator legislation, and others lag far behind. What most lift manufacturers want is a level playing field so they can do business across the whole of India and know where they stand. At the same time, it’s important that legislators consider the needs of smaller manufacturers so that any nationwide lift legislation is realistic for them to implement without going bust.

If nationwide legislation can be achieved, a secondary benefit will be to help make the Indian elevator sector more competitive globally in exports. It is true that the Indian government already sets strong regulations, such as the Indian Bureau of Standards’ National Building Code of India for elevators and escalators. We should enhance these regulations further to bring us on par with global norms.

We live in an era of ever-larger office blocks and housing complexes. This means that elevators are moving from being a luxury to a necessity. Because of this, we are seeing strong growth in the elevator industry in India. So, along with any new legislation on elevator safety, it is also increasingly important that there be accepted protocols on what to do in case of an elevator breakdown. At the moment, some elevator OEMs and end users implement breakdown protocols themselves, but we need better guidance in this area, because, during an elevator breakdown, the absence of established safety protocols can lead to accidents. In the meantime, I urge all elevator OEMs and end users to review their own elevators and implement their own protocols if they have not done so already.

Elevator safety ties directly into the issue of reliability and maintenance. Of course, the best starting point is to ensure you buy robust and reliable products. In India, industrial environments can be somewhat tougher than they are in other countries. You want to be sure your supplier has designed its products with the local Indian market in mind, ideally using R&D and India-based market research. When your elevators do break down, you will need local maintenance. If you are a small OEM, it can be enough to buy from a manufacturer with localized engineering support facilities in your area. If you are a larger company with operations across multiple states, you will want to choose an elevator component supplier with a Pan-India presence.

One interesting point about elevator safety is the rapidly emerging new lift of the COVID-19 era. We are all trying to maintain our 6-ft distance from one another; one of the toughest places to do this can be in an elevator, particularly one serving a large, busy office block in the morning. We can hardly stop going into the office, so proper precautions are essential. Where possible, many people are trying to avoid using elevators at peak times. Sometimes this means coming into the office later, or sometimes it means taking the stairs. I have also noticed people voluntarily limit lift occupancy to four (one person for each corner) and avoid speaking. Where OEMs and end users can help is by making an effort to reinforce some of the lift etiquette evolving naturally. This includes implementing a temporary two- or four-person occupancy limit and clearly marking separate corners with bright tape so people know where to stand.

In the future, I think Internet of Things (IoT) solutions will be increasingly important in elevators as a way to improve reliability and avoid equipment downtime by helping OEMs monitor diagnostics remotely. Remote monitoring using IoT can also help with predictive maintenance. COVID-19 has made contactless elevator-calling systems popular technology.

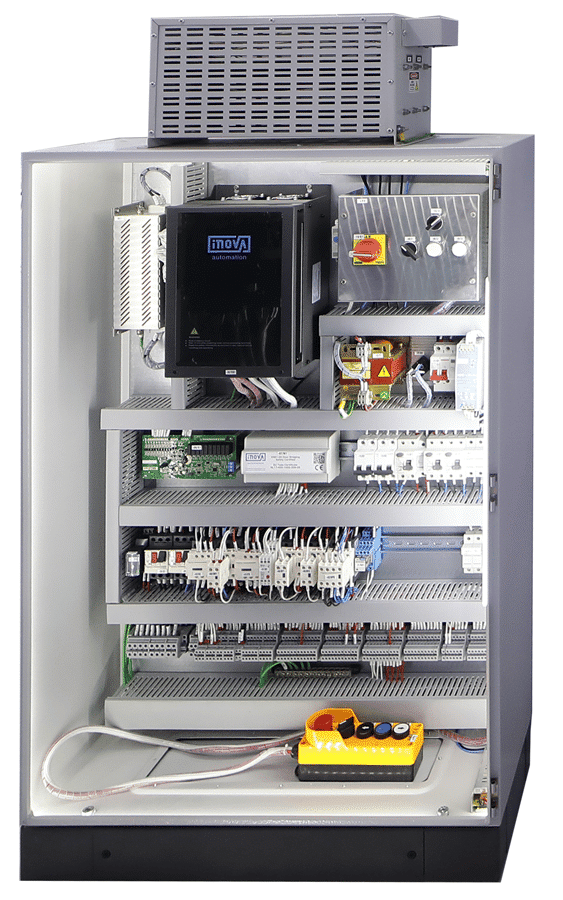

For me, elevator safety and maintenance are absolutely core responsibilities. That’s why, here at Monarch, we see government recommendations as only a baseline minimum that we always try to exceed. One of the ways we do this is by working wherever we can to ensure our products (such as our DCS, p. ??) meet both Indian standards and, where possible, EN 81 European elevator safety standards. For maintenance purposes, we have service operations in almost every region of the country.

Get more of Elevator World. Sign up for our free e-newsletter.