Comparison of Dedicated and Swing Public/Service Elevators in Hospitals

Mar 1, 2011

This article investigates the challenges of swing public/service elevators in hospitals and the factors to consider while providing a dedicated service elevator.

by Samson Rajan Babu

photos courtesy of Hydraulik–Liftsysteme Walter Mayer GmbH, InterMetro, Cambro, Schindler, Lobby Solutions, Swisslog, Construction Specialties and Dural GmbH

Introduction

This article investigates the challenges of swing public/service elevators and the factors to consider while providing a dedicated service elevator. In a modern hospital project, architects recommend a variety of elevator types: public elevators, bed service elevators, staff elevators, general-purpose goods elevators, dumbwaiters, and both sterile and soiled theater elevators. Architects typically wish to reduce the number of elevator cores to the minimum possible in order to gain more usable space. There is often a tendency to double the role of public elevators to move materials, supplies and service/ support personnel. It is also common for public elevators to be used to transport patients confined to beds and wheelchairs.

Description

A service (or “bed service”) elevator allows the vertical transportation of materials, supplies and miscellaneous goods. It also helps segregate movement of tradespeople, service and maintenance personnel on duty. In a hospital, it could also be used to transport non-ambulatory patients confined to beds, wheelchairs and stretchers.

Typical Features

- Large payload

- Deeper car (to accommodate bed-/stretcher-shaped items)

- Side-opening telescopic doors

- Simple and sturdy cab finishes and flooring

- Crash rails

- Access security controls

- Key controls

- Serves all floors, including basements and mechanical floors

Typical Arrangements

A service elevator can be provided in several arrangements, such as:

- Dedicated service elevator: The service elevator is located away from the public elevators and has its own service approach lobby and staging areas. The elevator core shape corresponds to deeper car types for the transport of stretchers, carts, etc.

- Swing public/service elevator – common public lobby: The service elevator is among the public elevator group, and the main lobby is also used as a service lobby and staging area. The elevator core shape could be for a standard, wider passenger elevator car. This shape cannot accommodate stretchers. Alternatively, the service elevator core shape could be for the deeper car type, with the remaining public elevators for the wider car type. This results in a staggered elevator core shape that could negatively affect the surrounding rentable area.

- In rare cases, the entire public elevator group and service elevator are arranged in the deeper car type to achieve a uniformly shaped elevator core. While a deeper car serves well for service traffic, it is not a preferred arrangement for passenger traffic. Deeper car types cause longer passenger transfer times at each stop, affecting round-trip time. In addition, the passengers stand as in a queue inside the deeper car, which is an undesirable feeling.

- Swing public/service elevator – rear service lobby: The service elevator is among the public elevator group but has a through-type car with two car entrances at 90º. The front entrance is used for passenger traffic, while the rear entrance is used for service traffic.

Typical Control Systems

- Independent control mode: Service elevators are usually provided with independent key controls and card readers to take command of the elevator for service use. This is the ideal operation mode for service elevators, with which the service traffic is handled separate from the public traffic.

- Rear-entrance operation mode: Service elevators adjacent to public elevators and/or part of public elevator groups are provided with “group separation operation” controls and a dedicated set of car operating-panel and hall-call stations, and indicators for rear-entrance operation. Using a “group separation control,” the public elevator is removed from the group and becomes a single service elevator. It then operates exclusively based on commands from the rear-entrance controls.

Hospital Traffic Movement

In a hospital, there is a wide range of materials, equipment and supplies that need to be transported to various floors through the service elevators (Figure 1). Operatives and service personnel also require service elevators to commute to upper floors. Materials and supplies are different types that cannot be mixed but need dedicated trips. Items such as hot food require rapid distribution. Material movement within a hospital can be affected

by manually operated carts and trolleys or automated guided vehicles.

Typically, the following types of service/personnel movements are observed within a hospital:

- Patient beds and wheelchairs

- Linen carts

- Meal carts

- Hot food distribution

- Nourishment distribution

- Housekeeping, stationery and administrative equipment supply trolley

- Scan/portable medical equipment movement

- Pharmacy/clinical supply trolley

- Waste collection (medical and nonmedical) trolley

- Sterile items supply trolley Continued

- Janitor, maintenance and support staff movement with tools and trolleys

In addition to the general service traffic, non-ambulatory patients’ movement is also necessary to move patients to treatment/scan areas and operation theaters. Here, two to three attendants accompany a patient. Depending on the number of beds, transport cart sizes, dimensions and volume of materials and various other operational factors, the required number of elevator trips must be calculated, and the total duration of elevator usage for hospital traffic movement must be calculated.

Dedicated Service Elevator

Advantages

Improved traffic flow: In large hospitals with a considerable number of upper floors and high occupancy rates, the service traffic is high. By segregating and diverting the service traffic to the dedicated service elevator, the public elevators’ performance is unaffected with regard to waiting times and trip times, especially during peak hours. Also, public lobbies are clear of obstructions, enabling faster public passenger transfers in and out of elevator cars. Apart from everyday traffic, damage and repair is restricted only to the dedicated service elevator, and “time lost in repair” does not affect the performance of the public elevator group.

Improved hygienic conditions: Patients within a hospital have weak immune systems and are thus prone to infections. By using exclusive bed service elevators for patient movement, infectious germs and contaminating agents brought in by the visitors are restrained from spreading to the patients. Also, any undesirable personal hygiene practices of service elevator users is limited to the service elevator. Finally, improper disinfection and sanitizing of car interiors, and dirt, mold and fungi buildup and odor inside a service elevator could otherwise affect a sick patient.

Contact/droplet/airborne germs are generally present in a common/public service elevator, as it carries sick patients. Such germs can infect visitors when they touch contaminated surfaces and objects (such as handrails or push buttons). By using a dedicated bed service elevator, visitors are protected against such infections. This also protects visitors against hazardous wastes and sharp objects.

Disadvantages

Larger floor plate: Depending on the preferred service elevator’s location within the plot limit, the floor plate may need to be increased in order to accommodate the service elevator cores, lobbies and staging area. A large service lobby and staging area must be provided to match the various turning radii of items moved. Rentable space is lost to the dedicated service elevator.

Restrictions on material and service personnel flow: With a dedicated service elevator, the operatives should use a specific predetermined route to approach and exit the service elevator. This route is typically laid away from the main circulation routes and calls for more time spent to reach a destination, which is often directly above the origin.

Additional costs: A dedicated service elevator adds to the project’s investment, operating and maintenance costs. It also mandates additional expenses on the structural elevator core; mechanical, electrical and plumbing service; fire and life-safety equipment; communication systems; and building-management equipment.

Swing Public/Service Elevators

Concerns

Some concerns of healthcare planners about swing public/service elevators include the following:

- Public traffic into sanitized service zones: There is no control of visitor movement, and visitors could penetrate other hospital zones. These are usually kept sanitized and are prone to contamination from visitor traffic.

- Cross infection between patients and visitors: Patients sick with communicable diseases can infect unsuspecting visitors. Similarly, visitors with or who recently had communicable diseases can transfer germs to newborns and patients with weak immune systems.

- Unpleasant experience and breach of privacy: For visitors, looking at patients on wheelchairs/stretchers could be an unpleasant experience. Similarly, a patient’s privacy is breached when unknown visitors see the patient, possibly causing embarrassment to the patient.

- Tidiness and hygienic environment: General service traffic (materials, food, supplies, etc.) brings in debris, dirt, odor, spillover and stains. When not cleaned and sanitized properly, these can cause mold and fungi buildup inside the elevator car. Thus, a healthy environment cannot be guaranteed within general service elevator cars at all times.

- Injuries and health risks: General service traffic could leave behind sharp objects, fluid leaks and radioactive objects inside the public car. Sharp objects could cause injuries to visitors and cause further infection. Hazardous healthcare waste could leave behind traces of infectious agents and spread to visitors, causing further infections.

Other concerns about these elevators are:

- Service elevators have larger capacities when compared to public elevators. However, a service elevator is allowed to operate at a lower speed than public elevators, only needing to travel between the terminal floors within 60 seconds. However, when part of a public elevator group, the “upgraded service elevator” cannot be slower, but must operate at a high speed in order to satisfy the criterion of travel time between destination floors. (The public elevators in a hospital must travel between the terminal floors within 24 seconds.) In effect, this combination increases the initial equipment cost.

- Housekeeping, service and maintenance operatives (with their tools and carts) must share the same lobby as the visitors do. Visitors find it difficult to move in and out of the lobby, and this increases passenger transfer times. This also results in an untidy lobby.

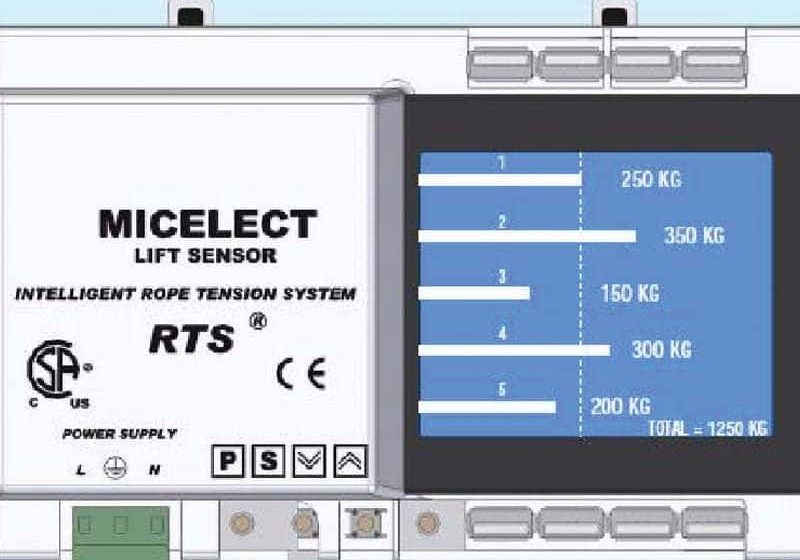

- Depending on the codes followed for a specific project, there could be a risk of overloading the swing service/ public elevator car beyond the machinery capacity. For example, Japanese elevator codes (Figure 2) allow 3.75 m2 for a 1000-kg capacity bed elevator. When used by the public, the same elevator (due to its larger car area) could be overloaded up to 80%. This could lead to a very unsafe situation.

- Service elevators are required to handle large beds, furniture, etc. For this purpose, the entrance door size (width and height) of a service elevator is quite different from that of public elevators. Hence, a service elevator’s entrance door stands out in a public elevator lobby due to its unusually large size, (Figure 3). Increasing the entrance size of a public elevator to match that of a service elevator would only lead to unnecessary equipment costs.

- Since service elevators handle large beds and other furniture, their lobbies must be spacious in order to accommodate the turning radii with a sufficient working clearance (Figure 4). When the service elevator is part of a public elevator group, the lobby needs to be much wider and deeper when compared to a public-only lobby width and depth. More rentable space is lost, which is loss of revenue.

- It is always preferred to double the role of a service elevator as a firefighter’s elevator. When there is a dedicated service/firefighter’s elevator (away from the public elevator group), it results in “redundancy by location,” as any fire in the public elevator area will not affect the service/firefighter’s elevator. However, if this elevator is part of a public elevator group, then any fire at the public elevator area will shut down the elevators, including the service/firefighter’s elevator. This will deprive the firefighters of an effective means of vertical transportation for firefighting and rescuing.

Advantages

- Cost savings: Initial investment cost is reduced, and cost savings are made by eliminating an additional service elevator and the related elevator infrastructure equipment. Running costs pertaining to operating and maintaining an additional service elevator are also eliminated.

- More rentable space: By doubling the usage of a public elevator as a service elevator, valuable rentable space is freed on all floors.

Disadvantages

- Cab interiors and entrance architraves of a public elevator could be invariably damaged (even with the use of protection pads) when used as a service elevator.

- When damaged, repair takes time and requires shutdown of the public elevator. Until repaired, it presents an inferior look to the public.

- Odor, dirt, trash and stains are usually left behind after service use. Continued

- Negative effects on the originally planned handling capacity and waiting time of the public elevator group.

- Under certain conditions (such as defective controls or a lost key), the service operatives may end up using the first available elevator in the public group for service traffic. All the elevators in a public elevator group will then be exposed to these disadvantages.

Design Considerations

Dedicated Service Elevator

If planning a dedicated service elevator or bed service elevator, the following should be considered:

- Based on number of floors and beds, and operational factors, estimate the required quantity and intensity of bed, wheelchair, trolley and cart movements, and other maintenance/service personnel movements.

- Estimate the “running elevator hours” consumed exclusively for bed/material movement. Justify the requirement for a dedicated service elevator.

- Estimate car floor size, car clear height according to desired cart/trolley sizes and their quantity per trip, and the size of the largest equipment moved through the elevator.

- Estimate payload capacity according to the desired cart/ trolley loads per trip and the weight of the largest equipment moved through the elevator.

- Allow for a service entrance lobby with suitably sized staging and operating space. The lobby must be self-contained without extending into other functional space.

- Allow for sufficient lobby width for the turning radius of the equipment with the longest dimensions.

- Estimate door clear width and height according to the largest equipment dimensional requirements.

- Locate the service elevator core away from public elevators to increase the redundancy level during fire emergencies.

- Verify the availability and connecting lobby to the alternate service elevator should the main one fail.

- Avoid dirt-catching, hard-to-clean crevices, recesses and joints inside the car.

- Use heavy-duty floor tiles with good tile grip or checkered plate flooring within the elevator car.

- Use coved-end flooring to facilitate easy cleaning (Figure 5).

- Use easy-to-clean, smooth stainless-steel finishes for cabin interiors.

- Verify elevator interface requirements with automated guided vehicles.

- Allow for bumper/crash rails inside the car on all three sides.

- Allow for kick plates at the bottom level of the car to absorb tire impacts.

Swing Public/Service Elevators

If planning a swing public/service (or a swing public/bed service) elevator, the following should be considered:

- Estimate the required quantity and intensity of movements and “running elevator hours” as described above. If this figure is large, do not use a swing public/service elevator.

- Schedule the service trip timing so as not to clash with peak-hour public traffic.

- Avoid hot food distribution, which can create intense traffic within a short duration (usually within 20 minutes). Instead, allow for devices at each floor to reheat the food.

- For nonperishable items (such as linen and administrative supplies), provide storage shelves at upper floors and replenish stock during off-peak hours.

- Do not also use the public entrance lobby for service traffic. Always provide dedicated rear service entrance and a rear service lobby.

- Use special operating modes, communication devices, delay alarms and visual indicators, forcing operators to use the swing public/service elevator sensibly and to return the elevator to public service promptly.

- Devise suitable operational procedures (forms) to control and authorize the use of a public elevator as a service elevator (Figure 6).

- Allow for crash rails and permanent hooks at the top level of the car for removable car protection pads (Figure 7).

Operation and Maintenance Considerations

In both dedicated and swing service elevators, implementing the following operational procedures can help organize the service traffic evenly and improve public health and hygienic conditions within a hospital:

- Devise and implement material/service personnel movement policies and monitor compliance. Address issues such as authorized usage and approved timelines for service elevator usage, and record the duration of service elevator usage.

- Include access security (card readers, passwords and keys) for gaining exclusive command of elevator car (Figure 6).

- u Include floor access security for sterile floors, burns-unit floors, etc.

- Always use fully covered trolleys and carts, and soak-free disposal bags to transport loose or sharp objects. Handle odor and stains securely and discreetly.

- Maintain schedules for regular cleaning and sanitizing service elevator cars. Conduct regular audits on schedule compliance and surprise checks on the car interiors.

Conclusion

A hospital is a space for the sick to recuperate, and it should provide a comfortable healing experience for patients and chaperones. For visitors, a hospital is also a space that should be hygienic. For healthcare professionals, a hospital should also be functional, and easy to use and maintain.

A hospital operator cannot afford any shortcoming on patient comfort, hygiene or public health. This could be detrimental to the business aspirations of the hospital. Expert selection and arrangement of transportation and circulation elements are extremely essential in order to maintain high levels of patient comfort, patient privacy and public health. As consumer demand and awareness for services and quality of services increase, it is the author’s understanding that a dedicated service elevator will soon become the norm of the healthcare industry.

References

[1] AIA Guidelines For Design And Construction Of Health Care Facilities: 2006.

[2] Health Technical Memorandum 08-02: Lifts: 2010.

[3] CIBSE Guide D: Transportation Systems in Buildings: 2005.

[4] Japanese Industrial Standard A 4301:1983: Sizes of car and hoist way of elevators.

Samson Rajan Babu is a senior vertical transportation engineer for Burt Hill, a Stantec Co. He offers expert elevator traffic analysis, group planning, vertical-transportation system design, specification writing, tender management, post-contract construction management and project execution quality control for elevator and escalator systems. Babu is also responsible for interfacing with other trades. He has 11 years’ working experience in elevator/escalator group design, specification development, post contract, project management, installation management, and project sales of elevators and escalators.

Get more of Elevator World. Sign up for our free e-newsletter.