Crescent Heights

Jan 1, 2024

Private-Residence Lifts

Calgary, Alberta, Canada

submitted by Global Tardif and ElPro Elevators & Lifts

Global Tardif Elevator Manufacturing Group, a manufacturer with 40 years of experience, wishes to present in collaboration with its loyal customer ElPro Elevators & Lifts, a prestigious and unique round panoramic elevator. ElPro Elevators, a company based in Calgary, Alberta, Canada, is renowned for its high level of expertise as an elevator installer with more than eight years of experience on several unique projects.

This four-stop elevator is a round panoramic 1360 kg, 0.5 m/s, in-ground telescopic. This daring, original and magnificent residential project took several years from ideation to completion. Every element of this elevator had to be carefully considered, from minor details in the design to the high-custom fabrication to the challenging installation on-site.

One of the most demanding challenges, besides the round aspect of the elevator, was to be able to conceal all the technical components a normal elevator would have: the wiring, the switches, the reader, the conduit and the mechanical parts. The goal was to have as seamless and refined a design as possible. The use of distinctive materials, such as the black stainless steel, provided by Royal Decor Steel, and the curved glass, are some of the unusual components used in the manufacturing of this round panoramic elevator.

The fabrication of the formed material that assembled this round elevator was made internally at Global Tardif’s factory. The small platform radius of this elevator represents the smallest radius made by the Global Tardif team to date. The small platform radius, in addition to a large opening width and considering the front and rear opening, created a great engineering challenge. Global Tardif engineering had to be creative in the design of the door operator and related equipment design. These parts and the design had to be made in house. No supplier was able to provide and manufacture this type of opening due to the complexity of its mechanism.

The manufacturer’s challenges were to design the product as requested by the customer and respect every detail of that design. Creating this elevator took Global Tardif’s engineering team several weeks of reflection; the use of sophisticated, resistant and fragile components prompted the team to design the project to avoid damaging the material during the shipping and installation process. This resulted in a finished product ready for installation without causing too much concern for ElPro Elevators, which had to meet the challenge of installing the product using installation methods and techniques described by Chris McClary, vice president of ElPro Elevators & Lifts.

Project Details

Sitting on the ridge of the prestigious community of Crescent Heights in Calgary, Alberta, is one of Alberta’s most beautiful homes. Inside that home is an ElPro Elevators & Lifts one-of-a-kind round panoramic elevator. This project was four years in the making, from idea, design, manufacturing and then installation. Every piece of this elevator and project had to be thoroughly thought out, from minor details of how to hide the wiring to complex pieces of how to mount the reader system to a round car top. Straight from the beginning this project had its challenges.

Originally, the home design was for a square elevator, but the property owner wanted a showpiece that was unique and one of a kind. It took months of design work going back and forth with Cody Sheldan of Rockwood Homes, McClary and the architects at Dean Thomas Design Group to incorporate the round elevator into the plans.

After this, ElPro Elevators had many meetings to go over the aesthetics of the unit from the cladding to how to hide mechanical parts typically seen on other units to the custom cab and entrance color selected from Germany. The elevator was to be placed in a hoistway encompassed by custom open stairs. The stairway had intermediate landings that were not round like the elevator, which created some tight clearance issues. Placement of the guide rails had to be absolutely perfect, or these landings would be struck by the elevator.

Now that all the details were set in stone, it was time for the fun to begin. For a clean look, the elevator was to be a single-stage in-ground hydraulic. When the day finally came to drill the hole for the piston, the driller hit solid granite and burned out a drill bit. Since this project was in a residential area, dynamite drilling was out of the question. At this point, we had to go back to the drawing board.

ElPro Elevators reached out to the cylinder supplier (ITI) with our dilemma. ITI was able to make a custom three-stage in-ground piston so the hole could be 1/3 of its original depth. Once the piston problem was rectified, we then had to run PVC through the pit and slab of the home so we could hide the hydraulic line and wiring down the road. Placement of this PVC was critical. If it was in the wrong place even by an inch, it would have been visible and ruined the ultra-clean look we were after.

After this, the pit and slab were poured. The house then began framing. The framing of this house was so complex it took nearly seven months. A commercial steel company was hired to custom fit the stairs and HSS vertical beams for our rail brackets to be mounted, too. The HSS beams had to be placed perfectly out of the pit to create clean lines. ElPro was also going to use these HSS columns to run all necessary wiring so that none could be seen.

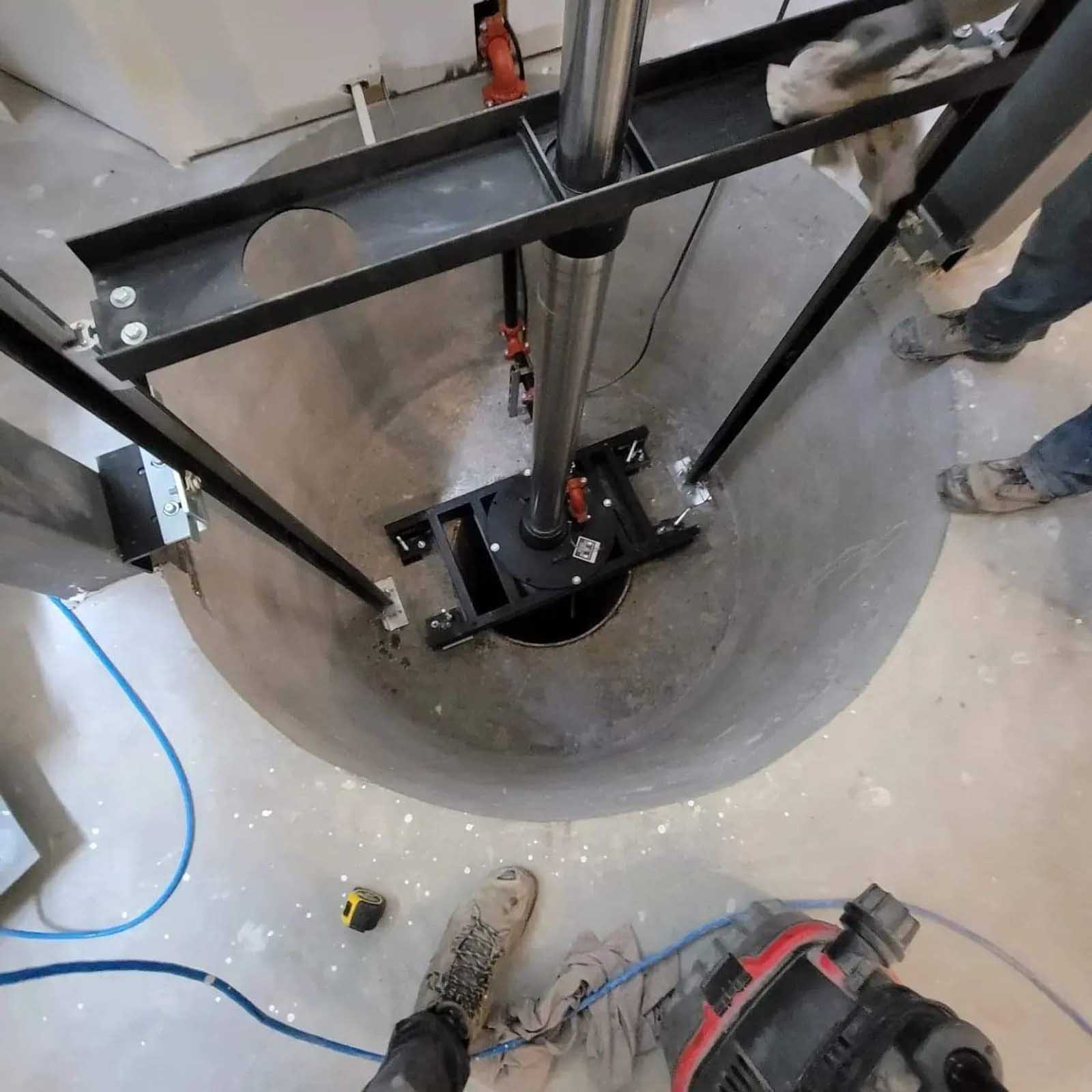

(Clockwise) Foundation to receive the custom three-stage in-ground piston; the finished round pit once the special hydraulic pistons has been installed; mounting car sling and platform in progress; the masterpiece structural design to accommodate the hoistway encompassed by custom open stairs.

Once the steel was erected and the house was mostly framed, ElPro Elevators mobilized on-site. ElPro was to do this project in a five-part installation. The first stage of installation was to install the guide rail, piston and car sling. Once we completed these items, it was then on to rough entrances. After all the basic mechanics were installed, painters then came in and powdercoated everything black. After this, ElPro pulled offsite for a few months.

Once we returned, the next stage was to finish frames and doors. The installation of the round frames and doors was tricky, to say the least. ElPro used a variety of plumb bobs, lasers and car references to make sure frames and doors were absolutely perfect. After that, we then ran wire through the HSS to all the landings and piped the wires over the headers to the hall buttons and doors locks. This was going to be cladded over afterward with the same custom color finished steel from Germany. We also had to fish the hall wires and travel back to the machine room located under the stairs on the basement level. The finished product has no visible wiring.

Once we completed this stage of the installation, we had to leave the site until the home was almost dust free to install the cab. ElPro Elevators returned to the site many months later to do the cab portion of the installation. Every piece of the cab was handmade and went together in a systematic way to hide all fasteners. The car operating panel was nothing more than a touchscreen and single button for the emergency phone.

After the cab was complete, we then began cladding everything to hide wiring and mechanical parts. The whole hoistway had custom cladding on the inside to hide the entrance king angles, headers and sub sills. On the outside, we installed custom cladding across the header to hide all the wires and pipes. ElPro then fabricated a custom top hat to conceal the mechanical components of the car top, creating a seamless finish. The pit was lined in a custom black checker plate to tie it all together. The installation was now complete, and it took more than two weeks to properly adjust and fine-tune the job after that.

McClary said:

“Since I started in the trade at a very young age, I had dreamt of doing a project that was one of a kind and took every ounce of my training and foresight. This was that project! For myself, this project is more than just a really unique and cool elevator. It’s more than a wonderful project in the portfolio for ElPro Elevators & Lifts: It’s a piece of myself spread over glass, steel and electrical components. I have done some amazing projects over my career, but this one — by far — takes the cake. Sitting in that stairwell is more than a custom elevator. It’s the pride every elevator company, mechanic or engineer should be taking in this wonderful craft we call our job.”

Credits

Elevator Manufacturer: Global Tardif

Elevator Contractor: ElPro Elevators & Lifts

Project Manager: Chris McClary

Home Builder: Rockwood Custom Homes

Architect: Dean Thomas Design Group

Project Manager: Cody Sheldan for Rockwood Custom Homes

Get more of Elevator World. Sign up for our free e-newsletter.