E2 Forum Returns – Part 1

Dec 5, 2022

Information from the grand opening until the congress dinner.

Under the heading “Elevate Your Knowledge,“ the e2 Forum elevator + escalator conference in Frankfurt Main, Germany, offered a simultaneous English-translated congress in two sessions on September 21 and 22, after a long break due to the pandemic. Forty-eight presentations in the newly renovated Congress Center at Messe Frankfurt (Frankfurt Trade Fair) were preceded by extensive advance coverage.

Approximately 350 participants made the most of the opportunities for communication: long coffee and lunch breaks on the move, as well as the atmospheric dinner. Further opportunities for conversation and information were provided by the 40 exhibitors. The previous event in 2018 had been attended by 420 people; all other numbers were slightly improved.

The next e2 Forum will take place on October 1-2, 2024.

In this first part of the report, you will find presentations from the first day of the congress, an interview with Roberto Zappa from the European Lift Association (ELA), a report on the accompanying exhibition and some impressions about the ambience of the e2 Forum. Part two will include presentations from the second day, an interview with Martin Schmitt from VDMA (German Mechanical Engineering Industry Association) and Trade Association Lifts and Escalators, as well as reports on the two e2 prologues in July and September before the conference.

All presentations can be found at e2 Forum Frankfurt

The conference addressed opportunities for buildings of today and tomorrow focusing on nine themes:

- Digital infrastructure — challenges and solutions

- The elevator in building design

- Building and modernizing existing buildings

- Cybersecurity

- Integration of elevators in modern buildings

- Urbanization, smart city, sustainability

- Digital, sustainable, safe

- Elevators and escalators in the urbanization process

- From maintenance to inspection

Grand Opening on the First Day

Uwe Behm, managing director of organizer Messe Frankfurt, opened the congress. As the trade fair partner, Schmitt spoke next. He interpreted “e2” in three different ways: as “elevator and escalator,” “second edition” after 2018 and “together and share.“ Together, the two partners are rolling out the e2 Forum worldwide to Buenos Aires, China, Milan, Mumbai and New Delhi.

Zappa greeted the group on behalf of the ELA. He described standardization as the key to sustainable development and education/training in conjunction with up-to-date information as the most important topic for the elevator industry.

Star architect Nayla Mecattaf, CroMe Studio, offered the first highlight right away in her keynote address, ”High-rise Buildings of the Future: Sustainability and Well-Being.“ She sees people at the core of buildings and of the city of the future, for which it is necessary to prepare with foresight. She underlined this with many examples from her company. The Chambers of Architects of six German states recognize this conference ”Innovation, Digitalization, and Sustainability – Opportunities for Buildings of Today and Tomorrow“ as further education.

Renato Turri from PSA Publishers and Zackes Brustik moderated the two parallel streams of presentations. Questions from the audience were asked directly via mobile phone to the respective moderator.

Day One, Series One Presentations

The presentations of the first day dealt with digitalization, standardization, planning and erection of elevators, energy efficiency and finding top quality staff. Hans-Wilhelm Dünn, Cyber-Council Germany, lectured on the topic ”Escalate and Elevate — We Need to Expand and Elevate Cybersecurity.“ He was followed by Prof. Dr. Boris Düdder, University of Copenhagen, with the lecture ”Cybersecurity – Challenges in Intelligent Passenger Transportation Devices.“

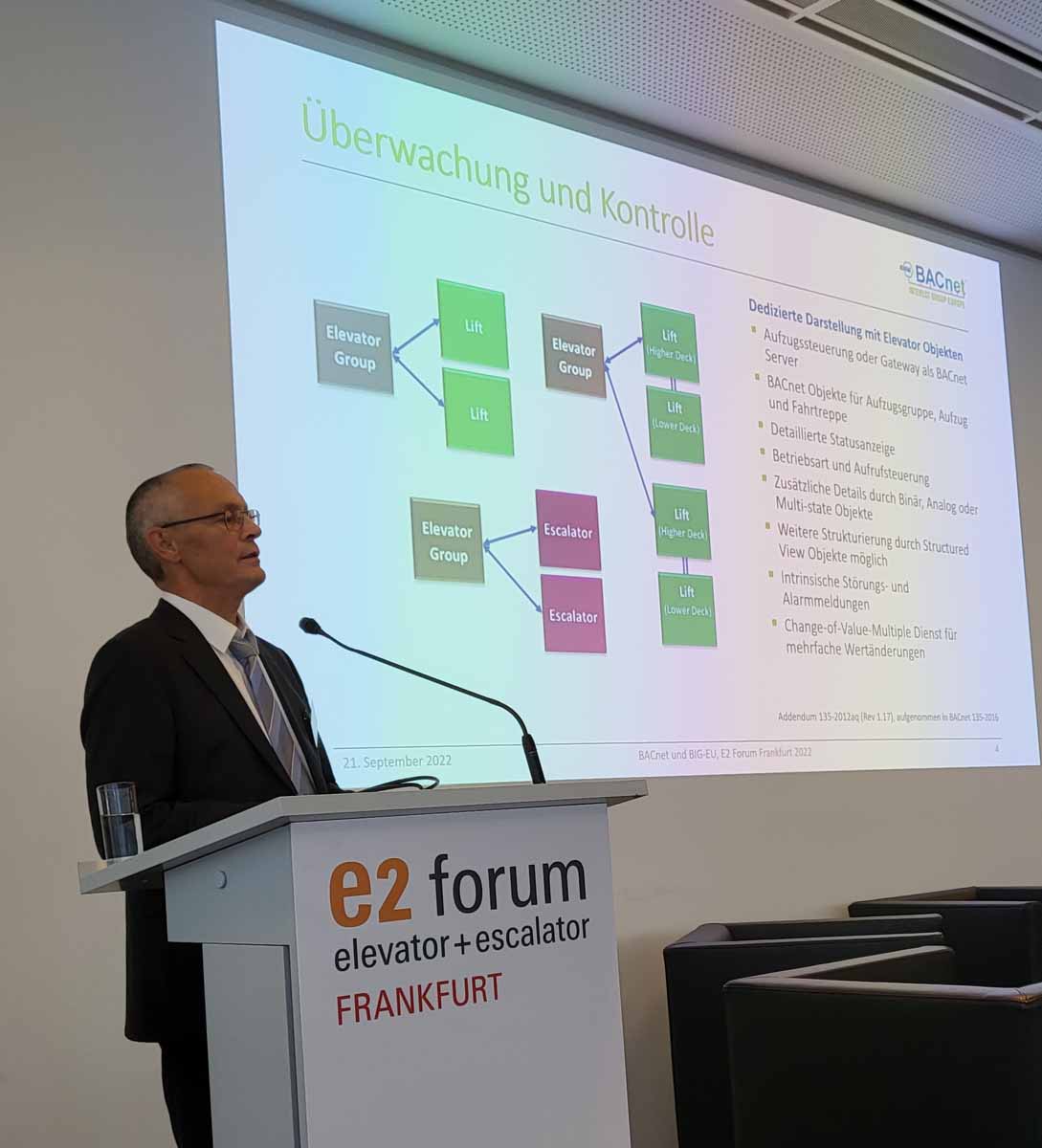

Bernhard Isler of the BACnet Interest Group Europe addressed the increasing integration of the elevator into the building under the title ”ASHRAE BACnet – What Belongs Together Comes Together: Elevator Integration, Evacuation, Building Automation“. BACnet, as a registered trademark of ASHRAE, is ANSI/ASHRAE Standard 135 resp. (EN) ISO 16484-5. The standard is handled by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), based in Atlanta, Georgia, USA. Further information can be found at ASHRAE and BACnet.

First, Isler dealt with the monitoring and control of elevators. BACnet offers a dedicated display with elevator objects for the elevator group, the elevator or escalator as clients on the server. Possible features include detailed status display and call control. Additional details can be added by binary, analog or multi-state objects. Structured View objects allow further structuring. Fault and alarm messages are intrinsic.

The system supports the many status changes and change-of-value (COV) of elevator systems on the client and server side — even when monitoring multiple buildings simultaneously. BACnet Interoperability Building Blocks (BIBBs) on the client side provide elevator object representation, control and data modification, COV multi-subscription (also server), event parameterization, as well as the recipient for events.

Concerning BACnet profile operator interfaces, Isler stated:

“The Elevator Monitoring Operator Interface family provides an elevator display and three workstation levels. It supports the display of elevator objects, uses subscription for multiple value changes, as well as supports changes and handling of error and alarm messages from elevator objects.”

In detail, he also presented BACnet profile elevator controllers: The Elevator Monitoring Controller family offers an elevator-only monitor and two elevator controller levels for limited or full control. It supports elevator and other objects, as well as multiple value change notification. Control is provided by the elevator objects.

Isler also addressed elevator operation for evacuation (OEO) when a fire is detected well away from the elevator lobbies. The floor with the fire has the highest priority. The floor on fire and the adjacent +/- two floors are served by the elevator for evacuation. If there is a fire on two floors at the same time, all floors between the two fires are served for evacuation. All other floors are not served during evacuation.

”Proper evacuation requires interaction between the elevator system and the fire alarm system,“ Isler said. The Fire Alarm System (FAS) detects fire and controls alarm and evacuation, including voice messages. The Elevator System (ES) controls the elevators through special evacuation routines for OEO including illuminated displays in the lobbies. The Fire Command Center (FCC) visualizes the fire in the building; it allows manual interventions in the FAS.

The FAS uses binary objects and multi-state objects to represent states and modes of OEO floors, as well as Life Safety Zone objects to represent OEO floors and zones. Three OEO signals through binary objects or physical wires provide high reliability and avoid the need for the FAS to be a BACnet client. Without BACnet, parallel wiring would be required for every detail on every floor.

This was followed by Dr. Michael Geisinger from Vonovia with the topic ”VAO: Digital Elevator Management at Germany’s Largest Elevator Operator.“ This session was concluded by a panel discussion on ”Digitization/Cybersecurity,“ in which Karl Heinz Belser for the BACnet Interest Group Europe, Geisinger and the previous speakers Dünn and Düdder took part.

This was followed by further presentations on the digital theme by Jürgen Blank, Schindler Germany, covering the topic ”Digital Mobility Solutions in Practice — Connectivity for the Future.“ ”Secure Data Communication of Elevator Systems in Digital Networks“ was the focus of Ralf Balzerowski’s, NetCom Sicherheitstechnik (security technology), presentation. Michael Bär from Bosch Service Solutions spoke about the ”Bosch Elevator Cloud — Status Quo and Outlook.“ Björn Kühnemann, Otis, followed with ”Digital Networking of Elevators: the New Generation.“ Frank Spickeneder from Telegärtner Elektronik dealt with “VdS-SecurIP.“

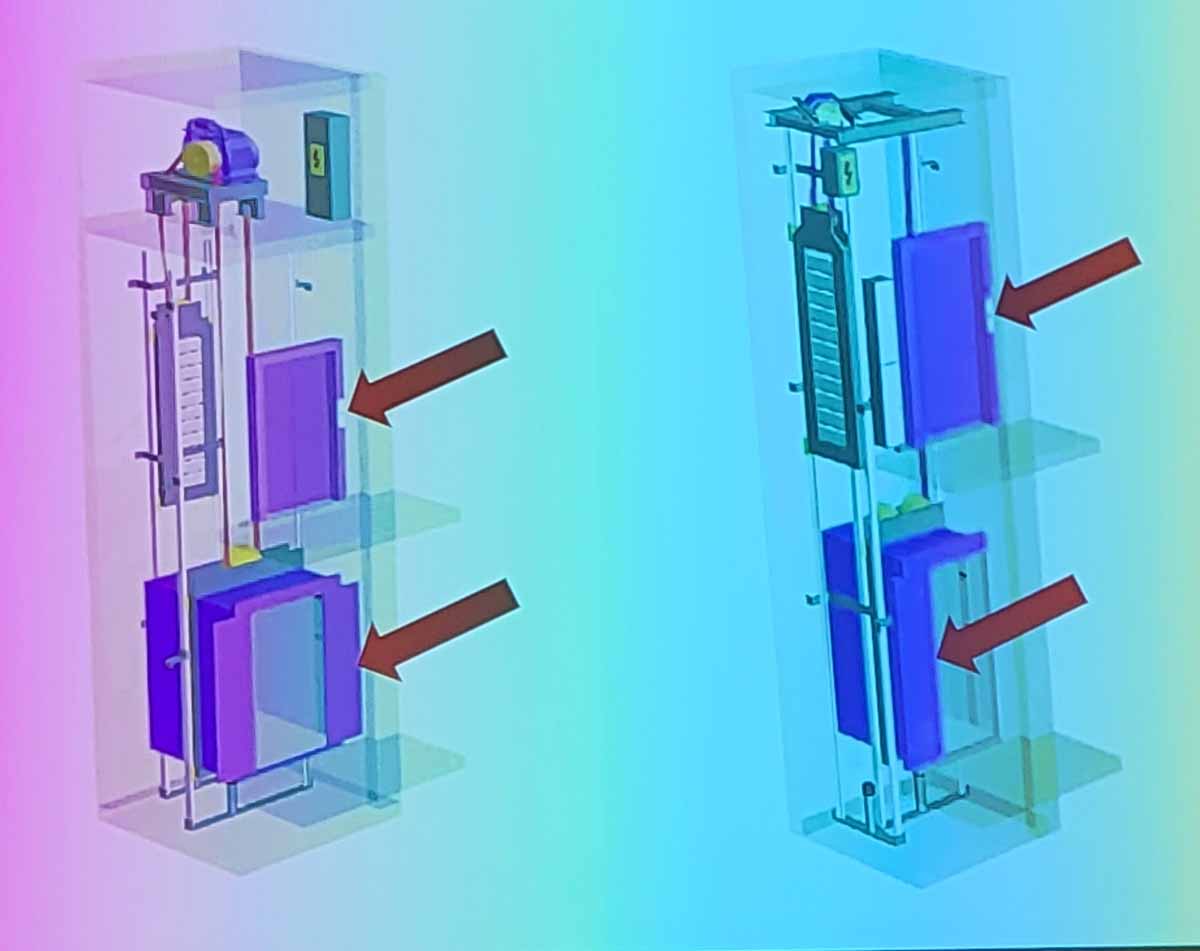

Andreas Hunziker, CEDES, concluded the first session with the HR aspect ”Is Digitalization the Answer to a Shortage of Skilled Labor?“ Fifty percent of all elevator mechanics will retire in the next few years. However, about 50% of all companies in Germany are unable to find suitable workforce to replace these retiring workers. It is necessary to combat the symptoms by improving the quality of training, offering better pay, furthering education and promoting the profession. Alternatively, we can simplify the elevator by shortening assembly times, reducing complexity, solving (technical) problems more efficiently, needing less maintenance, deploying fewer personnel, and providing more flexibly. Digitalization, e.g., initially by means of sensors and at the top level a smart building, can be a means to an end here, when in modern shafts many mechanical components are eliminated that previously had to be elaborately tuned to each other. One such elevator shaft can be seen in the Science Park in Landquart, Germany.

Day One, Second Series Presentations

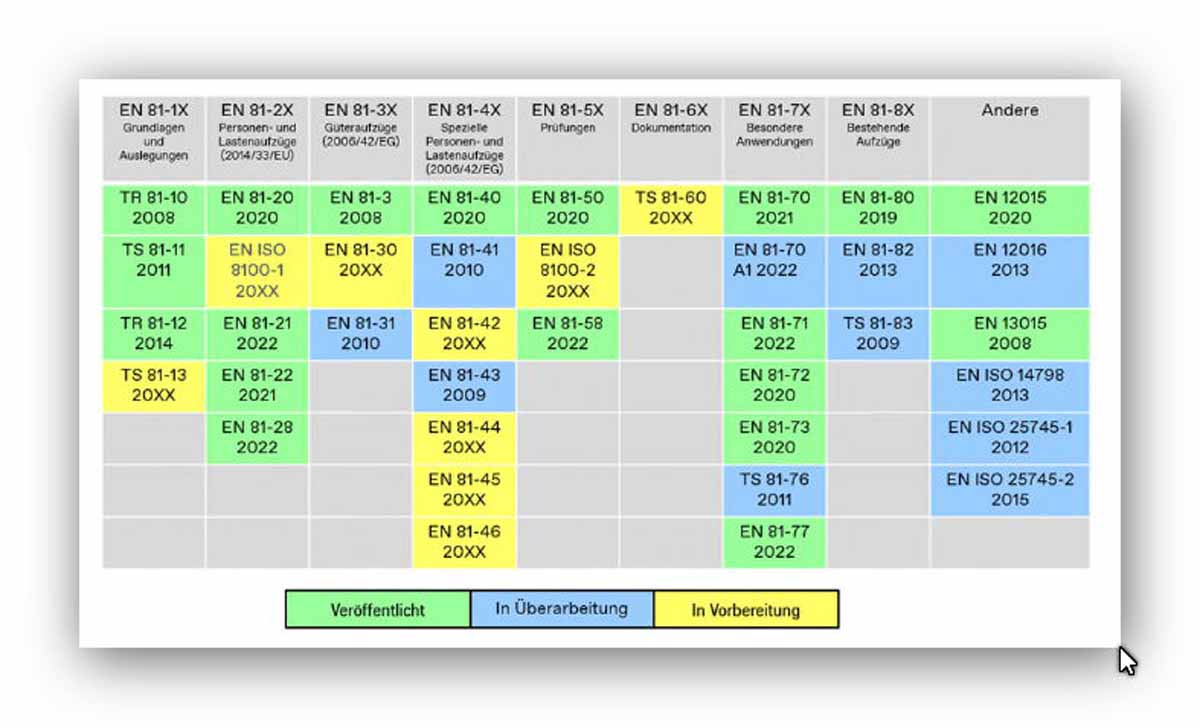

After the opening session, the first speaker in the second series was Dr. Gerhard Schiffner from CEN/TC 10 with ”Rules and Regulations in the Design of Elevators,“ which he defined according to eight criteria: intended use; number/size/speed; project-specific additional requirements, such as guide operation or load transport; European product requirements (see graphic); building regulations, e.g. Model Building Code; operational, e.g. Operational Safety Ordinance and ecological, e.g., energy efficiency requirements and performance, e.g., sound insulation/aesthetics, e.g., glass shaft.

The designated operation can be found in the VDMA guide, in which, among other things, building types plays a decisive role. VDMA also offers a planning guide on elevator technology for architects, planners, building owners and civil engineers. The AMEV offers a recommendation: ”Notes for planning, tendering and use of elevator systems in public buildings.“

Prof. Dipl.-Ing. Hagen Schmidt-Bleker dealt with Building Information Modeling (BIM) in elevator construction. He advocated openBIM, in which the IFC interface describes all building components and the BIM Collaboration Platform format BCF communicates and exchanges data with all other players. Important to him is object-oriented modeling, where you no longer draw, but the computer ”knows“ that this is a door, from which it generates the outlines, etc. As a ”single source of truth,“ all changes are always made in a single model. In this way, all the individual models are brought together, built up trade by trade. Construction happens first digitally, then in reality. The optimized evaluations are helping to make better decisions at an early stage.

The building owner also specifies for elevators in which form he requires which data, which then flow into the handling plan. This avoids collisions if, for example, stairs and/or escalators and/or elevators share landings. 3D interior views also of elevators and potential uses of rooms are then a byproduct. Light and elevator travel are also simulated. If augmented reality is added, then one can look at the model using a tablet or cell phone, which enables a target/actual comparison of planning/construction. For Schmidt-Bleker, BIM is just the basis for an ecosystem of building and city models.

Klaus Dahlfeld of Otis spoke about “Modular Construction — Elevator With Prefabricated Shaft“ with a degree of prefabrication of 85%. Among the advantages he cited are erection in two days, no storage areas, no construction noise, low coordination effort, high worker safety, high precision and quality, ability to be used in new and existing buildings, as well as a reduced need for skilled workers on site. Modular construction complies with elevator regulations. With many pictures, he presented the procedure from the planning phase through logistics and installation to completion.

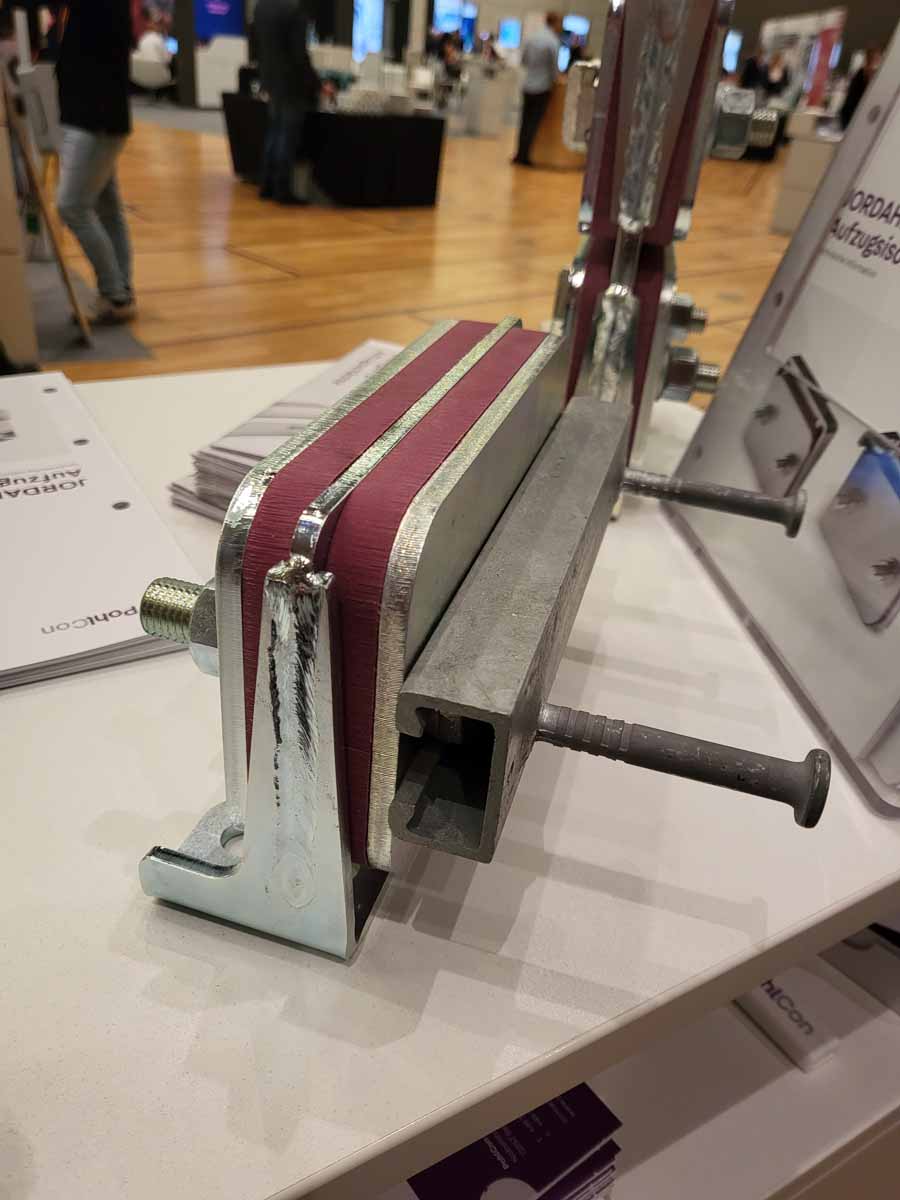

Prof. Dr.-Ing. Mazen Ayoubi from PohlCon dealt with sound insulation in elevator construction based on current projects with a focus on modernization. He described the sources of noise in elevators, explained what structure-borne noise is and what can be done to reduce it. A precondition for this is sound decoupling, for which his company offers a product.

For Heiko Nagorski of Bucher Hydraulics, the focus was on ”Modern Hydraulic Drives — Modernizing Instead of Replacing.“ Various product lines for low- and high-ride numbers enable energy savings of up to 80% and noise abatement of up to 10 dbA. Energy recuperation into the power grid up to 5 kW per unit and also intermediate energy storage is possible. The replaced components have a CANopen interface so that external access is available and, in the future, also the delivery of data to third parties, e.g., for predictive maintenance.

Adrian Gollasch from Telegärtner Elektronik, along with two partners, discussed campus solutions. Here, elevators are grouped together and for modernization equipped with hardware, software and services. The benefits include savings in subsequent costs through the use of existing infrastructure and the reduction of response times in the event of malfunctions and the escape of persons. The retrofit is customized and vendor independent. It is connected to the monitoring system, fire department intercoms and the remote emergency call center. Data from fans, heating messages and explosion alarms can also be received.

Thomas Lernet from Schmitt + Sohn elevators closed the session before the break with the ”Role of Elevator Doors in the Building.“ In elevators, doors are 80% of the cause of faults due to contact with users, and elevator construction companies must take this into full consideration. Also, the stress field landing door is fixed and car door travels along, leading to multiple fault variants. His conclusion: the simpler mechanical systems used to unlock and lock the doors, the less failure-prone they are.

After the break, Patrick Schweibl from D+H presented ”Systems for Elevator Shaft Ventilation as a Contribution to the Energy Transition,“ a simple and, therefore, common technical solution for saving energy in buildings, which relates to a component often retrofitted at the top of the elevator shaft. The German Building Code requires an opening for smoke evacuation of at least 0.1 m2 (approximately 1 ft2) and 2.5% of the shaft floor area; EN 81-20 requires ventilation of the elevator car. As a result, there is a permanent opening in the shaft head or machine room of the elevator. The heated or cooled air flows out through the elevator doors and ventilation opening (chimney effect).

Various institutions in Germany and Austria have calculated the heat loss under different general conditions resulting from this to be approximately 10,000 to 23,000 kWh per heating period. This corresponds to approximately 7.5% of the heat consumption. Approximately 500,000 to 600,000 elevator shafts in Germany are affected by this situation. If these losses can be saved, this corresponds to CO2 savings of 1.5-3 mT, a value that makes it worthwhile to search for technical solutions.

At bluekit.de, his company offers, among other things, a digital planning tool for configuring and calculating elevator shaft smoke evacuation solutions. Depending on the type of building (residential, hospital, office, high-rise office), the investment is €3,000-€5,000 plus €250-€400/year for operation, the savings €790-€2,000/year, and the payback period accordingly 5.5-3 years. A subsidy is possible according to the German Federal Fund for Efficient Buildings (Bundesförderung für effiziente Gebäude BEG) section 1.3 Accompanying Measures (as of October 2021).

This was followed by Harald Giehl, ALGI Alfred Giehl, on the topic of planning and digitalization of hydraulic drives and elevator systems. Volker Hager, Hydroware, gave a presentation on ”Networking of Elevators and Modern User Interfaces on Elevator Controls — From Nokia 6310 to iPhone.“ This was followed by ”The Power of Nature — From Disaster Back to Production“ by Boris Marjancevic of Fermator Germany. Fred Kowalsky from NAYARSYSTEMS then presented “Inclusion of IoT, Cloud and Multimedia in the Elevator.“ Also in this series, the day concluded with Nicolas Sacherer and Stefan Permoser from Permoser + Partner with a personnel-related presentation: ”Finding Skilled Workers in 2023 — This Strategy Worked.”

Trade Exhibition Offers Practical Relevance

In the spacious trade exhibition next to the lecture rooms, 40 exhibitors were present, two more than last time. Messe Frankfurt and VDMA also owe the good acceptance of the exhibition to their exhibitor advisory board, in which elevator and component manufacturers are strongly represented.

Many speakers offered the opportunity for in-depth discussions at their booths. Among others there were:

- Elevator manufacturers such as OSMA-Aufzüge (Elevators) Albert Schenk, Otis, Schindler Germany, Aufzugswerke (Elevator Works) Schmitt + Sohn

- Component manufacturers such as Danfoss Drives, Henning, Kollmorgen Steurungstechnik (Control Technique), Meiller Aufzugstüren (Elevator doors), Telegärtner Elektronik, Wittur

- Service providers such as BACnet Interest Group Europe, Bosch Service Solutions, Dekra Digital, TÜV Nord SafetyConsult, Association of TÜVs.

Elevator shaft ventilation for energy saving was also discussed several times. Among others, the companies D+H Germany with its BlueKit and Aleatec with its energy-kit presented their solutions.

Interesting solutions were also offered on site by:

- Bosch (Elevator Cloud): two-senses emergency call (hearing and seeing).

- Bucher Hydraulics: energy-efficient power unit Eco Line

- PohlCon: Jordahl elevator insulation JAI

- sensotek: access automation for elevators and escalators

In general, exhibitors expressed their satisfaction that the e2 Forum was again, finally, an opportunity for direct customer contact. Many new representatives from the industry were on-site. Whether an important target group of the event, ”architects,“ was sufficiently represented was difficult to judge on the basis of the audience. There was plenty of time for intensive discussions because there were slightly fewer visitors than the previous event.

Attractive Surroundings Facilitate Communication

Reunions, getting to know each other, discussions — the e2 Forum offered many opportunities to do this. Numerous coffee breaks and two long lunch breaks were situated between the lecture halls and the exhibition so that every new area of interest led to new people. At the evening conference dinner between the two lecture days, also on the exhibition grounds, people sat together for long hours to discuss specialist topics from the lectures in greater depth, but also to talk about new products and services from the trade exhibition. The newly renovated congress center, which can be reached quickly and easily from the main train station, the airport and by car, guaranteed an attractive ambience that made the conversations fizz after the long break.

Interview With Roberto Zappa, ELA

Roberto Zappa (RZ), president of the European Lift Association ELA, who opened the e2 Forum Frankfurt, spoke with your author (USB):

USB: How was ELA involved in this e2 Forum?

RZ: I have to confess; I was the founder of the e2 Forum. The first meeting took place in Milan, Italy, in 2016 while I was president of the Italian Elevator and Escalator Association ANIE/AssoAscensori. Thus, I am a strong supporter of the e2 Forum idea, also already when it moved to Germany for the first time. And there will be more e2 Fora in India and in China, where I will also hold the opening speech. This is an easy way for ELA to transmit our messages.

USB: What is your impression about the status of the elevator and escalator industry in these difficult surroundings, namely COVID-19, followed by delayed or missing components, then the war in Ukraine, followed now by the gas shortage?

RZ: The industry is healthy! Certainly, they suffered after COVID-19 and the Ukraine war, but elevator maintenance must be performed every day if need be. The lack of the electronic components make life in every industry more difficult: The costs raise; the availability of materials goes down. The energy aspect is affecting all industries even harder. The costs will keep raising; the construction industry — and with a certain time lag then the elevator and escalator business — will get less orders. But as our industry has a sound large portfolio in Europe with its ca. 6.6 million lifts, it seems a safe place to be and even more if we consider China with its ca. 8.5 million lifts, where many of our associated members have a strong presence. Under these conditions, we are exceptionally happy to be in this industry.

USB: What is the ELA position concerning the in-depth integration of elevators and escalators into the building and the other building services crafts?

RZ: The lift industry jumps right into the digitalization of buildings: We already cooperate strongly in the field of energy efficiency, and building automation is close behind. We intend to cooperate with all other actors working on a building. Whether we like it or not, interoperability is a MUST! We will do our part and compromise in the interest of our customers and industry.

Get more of Elevator World. Sign up for our free e-newsletter.