The company’s “learning that drives customer care” approach has served it well.

KONE’s approach to learning and development is simple: develop a winning team of true professionals. That effort is one of the company’s five strategic targets, supported by the “70/20/10” approach to learning: 70% of learning at KONE is done on the job; 20% is through mentoring and coaching; and 10% of skills and competencies are acquired through hundreds of foundational-development programs offered online and through facilitated learning. Providing continual learning opportunities for all employees is at the core of one of KONE’s global values — “energy for renewal.” “A robust learning and development program is another great example of KONE investing in our people,” said Larry Wash, executive vice president at KONE Americas.

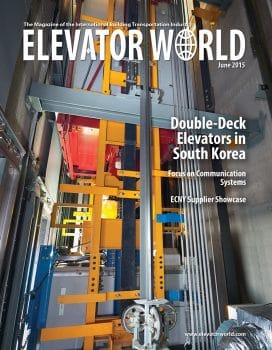

Technicians at KONE have several opportunities for thorough hands-on practice installing and maintaining vertical-transportation equipment. And, these techs have access to a comprehensive library of web-based, self-paced training programs.

KONE encourages employees to continuously develop their skills and capabilities to help them remain among the industry’s technical experts in vertical transportation. This helps to achieve two goals: making KONE a great place to work and delighting customers. The company’s emphasis on employee development helps customers trust the KONE team — from its sales professionals and installation experts through maintenance and support technicians — to truly understand and provide the best solutions for their vertical-transportation needs.

Supporting KONE Culture

The learning culture in the company is evident from day one. New onboarding and induction programs ensure all employees not only have the tools and equipment to begin their careers, but also understand KONE’s culture and their role in living out the company’s values.

In October 2013, KONE launched a learning management solution (LMS) providing all employees the opportunity to search the global training catalog, self enroll in training, complete web-based training at their own pace and track their progress along role-based learning paths. The first thing all new employees see upon login to their learning account is their enrollment in “New Hire Safety Training.” After completing safety training, they have access to a library of development opportunities that includes more than 100 on-demand courses offered as web-based, instructor-led or blended programs. These courses span a wide range of topics, from “Basic Elevator Component Identification,” to “Selling KONE’s ReNova Door Operator Modernization Packages,” to “KONE EcoSpace Installation Training.”

Blended Approaches

Technicians at KONE have several opportunities for thorough hands-on practice installing and maintaining vertical-transportation equipment. And, these techs have access to a comprehensive library of web-based, self-paced training programs. Maintenance technicians can practice service and repair on many popular controls, drives and braking systems at KONE’s Technical Training Center in Moline, Illinois. The facility offers hands-on training classes on industry equipment, classroom and simulator-based instruction, and quick-reference training videos. KONE’s Technical Support Help Desk assists maintenance technicians with diagnostics and troubleshooting of elevator and escalator equipment.

Hands-on safety training is mandatory for all KONE technicians. Each branch in North America has training equipment, such as elevator doors, electrical disconnects and electrical jumper kits on which technicians can learn and practice safe working habits.

Elevator and escalator technicians are part of a highly skilled trade and must continually develop their knowledge, skills and capabilities as new technologies are released. KONE technicians initially learn how to install and maintain vertical-transportation equipment through a comprehensive apprenticeship program provided by the National Elevator Industry Educational Program (NEIEP). During the course of a five-year formal curriculum, technicians start as apprentices and develop the skills and experience to be licensed mechanics. Their learning continues following their receipt of mechanic status with continuing-education courses provided by NEIEP, as well as the array of learning and development opportunities provided by KONE.

Customer Training

Any building management company, architectural firm, general contractor or other interested party in the U.S. or Canada has the opportunity to attend a KONE-facilitated presentation. KONE offers accredited presentations to earn continuing-education credits for the American Institute of Architects, U.S. Green Building Council and Building Owners and Managers Institute International. Five different presentations are available to inform participants about elevator technology, elevator maintenance, elevator destination control, escalator technology and Leadership in Energy & Environmental Design. Customers also have the opportunity to attend a KONE EcoMod™ seminar to learn about its escalator modernization solution.

Learning is an ongoing and integral part of the KONE culture, and new learning and development opportunities are continually being developed and delivered. The company’s centralized Learning and Development team works closely with business line leaders across the company to develop effective programs that help new industry members increase their speed to proficiency and help existing employees further develop their technical knowledge and expertise.

Get more of Elevator World. Sign up for our free e-newsletter.