Engineering Excellence

Apr 4, 2024

Next Level Elevators completes precision installation in Melbourne.

by Caleb Terpstra

Project Overview

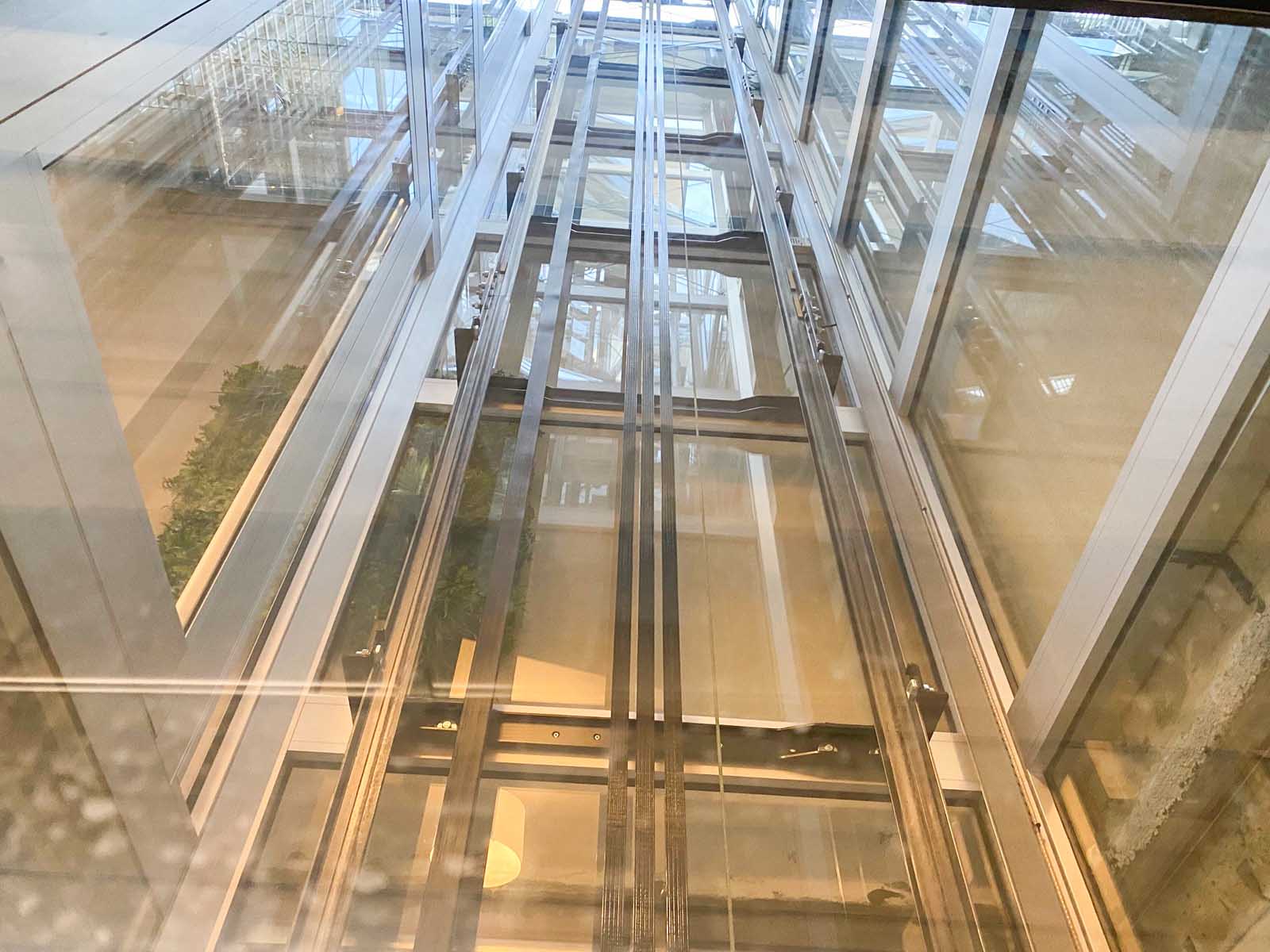

Lincoln Place is a complex residential project that required engineering excellence. The Melbourne, Australia, residence situated in the heart of the CBD saw Next Level Elevators install an elevator and shaft combination into a small and unusually shaped lightwell. The project required a beautifully appointed four-stop Eltec HLB elevator paired with Eltec’s iconic glass shaft (TA Freestanding).

Next Level Elevators worked closely with owner-builder Clive Miller, a retired civil engineer, to ensure the vision for the project was realized and executed to the highest standards.

Visual Requirements

With the elevator passing through four different levels, each with its own individual setup, it was important that the elevator wasn’t overly imposing but helped unify the various spaces. This was achieved via the use of a low-sheen anodized finish across the doors and shaft, along with sophisticated glass elements, helping the lift merge with its surroundings.

Practical Requirements

The clients required a custom elevator small enough to fit the lightwell, while being large enough to accommodate wheelchair access. This requirement meant there was only a minuscule clearance of 25 mm to spare around the lift shaft at specific points. The shaft had to be designed and engineered without any top fixing points because of the open rooftop. This requirement also had to be balanced with local council rules around height restrictions. With so many factors to consider, the planning and execution had to be meticulous.

Installation Considerations

The CBD location posed issues around site access, namely excavation work and the movement of materials. Limited access in the form of dense urban streets and restricted parking was addressed though flat-packed assets moved via an all-terrain forklift; this was done in conjunction with established traffic management processes.

Due to the layout of the property, materials had to be maneuvered up the shaft or transported via a narrow stairway in the middle of the property. The modular design of Eltec products meant most items could be moved with relative ease, while large components like glass panels were moved with purpose-made suction cups. As the installation took place during the winter months in an external void, the team had to overcome challenging weather and effectively waterproof the area.

These various challenges were overcome via our highly trained staff, innovative products and optimized installation processes. Preliminary sketches provide further insight into the practical requirements of the project. A video of the elevator in motion can be seen at Next Level Elevators POTY 2024.

Transportation System

This project demanded a flexible and innovative combination of products in the form of the Eltec HLB elevator and the TA Freestanding shaft. Designed and manufactured exclusively in Italy, the Eltec HLB is a highly customizable residential elevator with a flexible footprint ideal for difficult scenarios. The Eltec HLB boasts a VVVF (variable-voltage, variable-frequency) all-electric traction system that runs on a single-phase 10-amp power supply. The Eltec HLB was invented by elevator innovatior Gianluca Polensig (Eltec Lift s.r.l.) with the aim of replacing outdated hydraulic and screw technology for residential scenarios. Unlike hydraulic technology, no motor room is required, and everything is cleverly housed within the shaft — making it the ideal choice for this project. The Eltec HLB can be manufactured with a reduced pit and headroom to meet specific project requirements. The reduced headroom was essential in terms of meeting local council requirements pertaining to height restrictions.

The sleek profile of the Eltec HLB sets it apart and allows it to act as a stunning statement piece or a seamless addition to any interior space. The Eltec HLB strikes the perfect balance between style and functionality and can be customized with a variety of wall panels, flooring, mirrors, doors, lighting, buttons, displays, control panels, intercoms and handrails.

General specifications for the Eltec HLB can be viewed below:

The TA Freestanding shaft is a self-supporting frame made of aluminum which strikes a balance between lightness, strength and flexibility. The properties of aluminum also mean that the frame is resistant to corrosion over time and doesn’t require maintenance. This is essential, due to the shaft being located in an external lightwell exposed to the elements.

| Regulations Referenced | Australian and European |

| Drive system | VVVF all electric traction system |

| Country of origin | Manufatured in Italy |

| Capacity | 200-400KG (wheelchair capacity) |

| Maximum travel* | 20m |

| Number of stops* | 8 |

| Maximum speed | 0.3m/s |

| Pit depth | 180 mm |

| Headroom* | 2520 mm |

| Motor room | Motor and Controller housed within shaft |

| Power | Single Phase/230v10A |

| Emergency control buttons | Located by upper door |

The TA frame is quick and easy to install thanks to its ingenious interlocking system. Its exclusive interlocking system means no screws and wiring are exposed. This eye-catching structure can be finished in a myriad of sophisticated colorways. The TA Freestanding shaft is ideal for housing both lifting platforms and electric lifts with a capacity of up to 630 kg and a speed of 1 m/s. It can be developed for a height of 20 m.

General specifications for the TA Freestanding shaft can be viewed below:

Our team and innovative products were up to the challenges proposed by the project, and the outcome was a resounding success. The customer was exceptionally happy with the results and now has a residence that meets immediate and future needs.

| Type | Modular |

| Material | Aluminium |

| Structure | Self-supporting (no structural wall requlred) |

| Maximum height* | 20m |

| Country of origin | Italy |

| Packaging | Flat-packed(no crane required) |

Caleb Terpstra is a marketing professional with a background in digital transformation. Joining Next Level Elevators in early 2020, Terpstra has developed a passion for elevator design and technology and enjoys using his experience to promote the brilliant work being done across the residential elevator industry in Australia.

Clive Miller and Edward Hume contributed to this article.

Get more of Elevator World. Sign up for our free e-newsletter.