Fluke ScopeMeter

Dec 1, 2018

An examination of the handheld oscilloscope and how it can be used for troubleshooting a variable-frequency drive (VFD)

Electronic engineers and technicians often spend a lot of their time in information- gathering mode. If electrical equipment is malfunctioning or while they’re putting together a new prototype, it is essential to know what each device, circuit and stage is doing, and how they’re working together to form a functioning piece of equipment. To this end, we must perform tests and take measurements. In conjunction with block diagrams and schematics, knowledgeable professionals can find out what is going on and ascertain which actions, if any, are required. In repairing malfunctioning equipment, this information may lead to replacing a faulty component, while in engineering new designs, it may be a question of redesigning a circuit or whole stage, or altering the layout to mitigate radio- frequency interference or solve characteristic impedance problems.

To gather information, the multimeter and clamp-on ammeter are the usual tools of the trade. But, sometimes, more advanced measurements are needed, and this is where the oscilloscope makes its appearance, the multimeter standing ready nearby. This is particularly the case when elevator work is on the agenda, because the motion controller, variable-frequency drive (VFD), car and floor controls, fire-alarm connection and so on all may require a knowledge of the relevant waveforms.

Learning Objectives

After reading this article, you should have learned about:

♦ Different applications for bench-type and handheld oscilloscopes

♦ Acquiring a signal in the Fluke ScopeMeter

♦ Math function in the Fluke ScopeMeter

♦ Scope and meter inputs in the Fluke 190-502

♦ How to troubleshoot a VFD

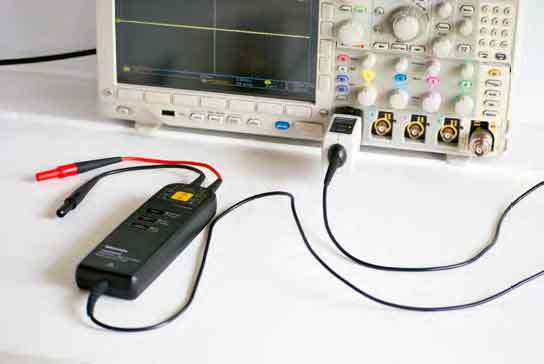

A very basic and essential oscilloscope for all kinds of electronic troubleshooting is the bench-type instrument, such as the Tektronix MDO3104. This is an excellent oscilloscope, and it or a similar model is needed in any shop or laboratory that does advanced work. The handheld, battery-operated oscilloscope is more suitable for the factory floor or in harsh field conditions, such as in an elevator machine room. An example is the Fluke 192-502 ScopeMeter.

The handheld oscilloscope lacks some of the advanced features found in a bench model, but one distinct advantage is that access to AC power is not required. The Fluke 190-502 ScopeMeter has a battery that can be recharged through an AC cord, either during usage or between sessions. If the battery is discharged, worn out or missing, the instrument can be operated on AC only. When operated on DC only, with the charging cord removed, the ScopeMeter is not prone to AC powerline interference. In an AC-powered bench model, this can make irrelevant noise in the display, masking anomalies in the signal that may need to be identified and corrected.

Another advantage of this handheld oscilloscope is that its case is thoroughly ruggedized to withstand harsh factory-floor or outdoor conditions. Perhaps the greatest benefit, however, is that all channels are isolated from ground and from each other. Users of the bench oscilloscope are made aware in the instrument’s documentation that point-to-point measurements in a circuit under investigation may be problematic. Specifically, if the ground-return lead of any probe is connected to a circuit, wire or terminal that floats at some potential above or below ground level while the oscilloscope is plugged into a standard three-wire receptacle, there will be a severe arc fault. This could damage the equipment under investigation or oscilloscope, or cause injury to the operator. This can happen even when the oscilloscope is powered down and/or the probe tip is not in contact with part of the circuit. It has to do exclusively with the ground-return lead. In taking measurements on many types of equipment such as VFDs, both sides of some circuits float at a voltage above or below ground. This is why the conventional bench oscilloscope is not suitable (unless it is equipped with a differential probe).

A differential probe is used with a bench-type oscilloscope when measuring floating ground voltages, but it is expensive and may be not available. However, the handheld oscilloscope can again come to the rescue. Some technicians saw off the oscilloscope ground prong to make sure a costly mistake will not be made, but the difficulty in this expedient is that the protection provided by equipment grounding is lost. So, in the event of a ground fault, the technician, rather than the wiring, may be lost.

The Fluke handheld 190-502 ScopeMeter, as its name implies, combines the functions of an oscilloscope and a conventional multimeter. On the top panel to the outside are two BNC ports for two probes to be connected to analog channel inputs. Between them are sockets that will accept ordinary voltmeter probes. Buttons on the front panel allow the user to choose between oscilloscope and DVM modes. A separate multimeter does not have to be carried out into the field when using the ScopeMeter.

Operating the Fluke ScopeMeter is similar to using a bench- type AC-powered instrument. If anything, it is simpler, but there are some aspects of the handheld scope that are unique. As for similarities, first-time users may encounter what they see as puzzling behavior. This generally boils down to not being able to get a good display. If this happens, it is helpful to restore the default settings. In most bench-type oscilloscopes, there is a button labeled “Default Setup” or something similar. Simply press the button to eliminate any strange settings that may persist since the last work session. In the Fluke ScopeMeter, the procedure is slightly more complex:

- Turn off the instrument.

- Press and hold the “User” key.

- Press and release the “Power” button.

- You should hear a double beep indicating that the instrument has been returned to the factory default settings.

- Release the “User” key.

If a waveform fails to display as expected, nine times out of 10, it will instantly appear when you push the “Autoset” button. The oscilloscope is essentially an auto-ranging voltmeter, and pressing “Autoset” facilitates this process. For any oscilloscope, when there is difficulty in getting a good display, defaulting and autosetting the instrument will usually solve the problem. (The ScopeMeter’s “Autoset” function button is labeled “Auto.”)

To demonstrate the ScopeMeter’s ability to display waveforms, connect the output of a function generator to analog channel A input. The Tektronix MDO3104 oscilloscope has an optional built-in arbitrary function generator (AFG) that works well in this application. One end of a BNC cable connects to the AFG output port on the back panel, and the other end goes into the Fluke Analog channel A input port on the top.

On the Tektronix bench oscilloscope, press “AFG.” The default waveform is sine. Any of a dozen others can be selected using multipurpose knob a. On the Fluke ScopeMeter, press “Scope,” and make sure channel A is on. The results are displayed in the ScopeMeter as the various AFG outputs are scrolled through in the Tektronix. (This is appropriate, because Tektronix and Fluke have both been acquired by the same corporation, Danaher.)

Again on the Tektronix bench oscilloscope, press the soft key that corresponds to “Waveform Settings.” Now, waveform frequency and amplitude parameters can be adjusted, and the changes will be displayed in the ScopeMeter. Notice that when you change the AFG signal amplitude in the Tektronix, the appearance of that signal as displayed in the ScopeMeter changes only momentarily and then reverts as the ScopeMeter’s autoranging function kicks in. What does change, however, is the number of volts per division, so the signal is correctly displayed.

Another very instructive exercise that is helpful for getting a feel of the ScopeMeter is to connect it to the utility power supply, accessed from a premises branch circuit. It is recommended that a plug and cord be terminated in a deep plastic wall box to perform this operation safely.

Trim off the green equipment- grounding conductor so it is not in the way, and cut the black hot wire and white neutral wire different lengths so they cannot contact one another. Strip off just enough insulation from these wires so that the oscilloscope probe hook tip and return lead alligator clip can connect to the exposed copper.

Disconnect the BNC cable used in the previous demonstration from the ScopeMeter. Connect a standard 10:1 probe that has been compensated to channel A and equipped with a hook tip to the black (hot) conductor and the ground return lead alligator clip to the white (neutral) wire. (Note that while it is customary to make the connections in this way, with the handheld, battery-operated oscilloscope, the connections could be reversed, and there would be no harm, because both sides are isolated from ground. This is opposed to the bench-type oscilloscope, where, as pointed out earlier, if the ground return lead is connected to any wire or terminal that floats above ground level, there will be a hazardous fault current.)

The utility sine wave should be displayed when the instrument is in scope mode and has the correct channel switched on. Again, you may have to press “Auto” to get a good display. As an experiment, you can connect various loads to the same premises branch circuit to see if the waveform is clipped or distorted, or exhibits noise. This power-quality measurement will indicate the stiffness of the utility power source and the adequacy of the premises wiring.

For the next demonstration, we’ll leave the utility power supply connected to channel A. Connect a 9-V transistor radio battery to channel B. With both channels turned on, the utility sine wave and 9-V DC signal are shown together on the same display, sharing the same X- and Y-axes. The DC signal is a flat horizontal line, slightly less than one 10-V division, either above or below the X-axis (depending on the polarity of the battery hookup).

The purpose of this exercise is to demonstrate the “Math” functionality of the ScopeMeter. Like modern bench-type oscilloscopes, the ScopeMeter is capable of depicting the result as a synthetic waveform when one signal operates upon another. These two signals can be identical or different, but they must be accessed through separate channels, either through probes or BNC cabling from one or more function generators. Also, as we shall see, some “Math” functions are applicable to a single signal accessed through one analog channel. They can operate on one or two inputs.

“Add,” “subtract” and “multiply” operations require two operands, designated “Source One” and “Source Two” and conveyed through channels A and B. (In bench-type oscilloscopes, these are termed channels One and Two). In all cases, each channel has a dedicated color, and the associated waveform is depicted in that color. The resultant waveform is shown in some color not used by one of the channels, such as gray.

“Add,” “subtract” and “multiply” require two operands, which are designated “Source One” and “Source Two.” “Invert,” “integrate” and “filter” require a single operand, designated “Source One.” The operations require that a destination be chosen. The steps that must be completed to perform a “Math” operation are:

- Press “Special Function” to open the “Special Functions” menu.

- Press “F3” to open the “Math” menu.

- Begin the operation by turning the “Math” function on.

- A box appears listing available “Math” operations. Choose one of these, and press “F4” to select.

- Use the up and down arrows to highlight source(s) and destination. Press “F4” to open the relevant boxes. Choose source(s) and destination, and press “F4” to select.

- The “Math” operation can now be chosen. “Add,” “subtract” and “multiply” cause the two waveforms to interact as specified, and the result is displayed as a third, distinctively color-coded waveform. In all cases, there is a point-to-point correspondence shown with respect to the X- and Y-axes.

Three additional operations can be performed on a single waveform. They are “invert,” where the polarity is reversed, and “integrate,” where the function calculates and displays the area under the selected waveform. This operation totalizes the waveform over time and is a measure of all the power dissipation. Also, there is “Filter,” which permits the waveform to be modified in specified ways.

A valuable feature the ScopeMeter shares with other modern oscilloscopes is “Cursors.” Early oscilloscopes had a transparent overlay on the screen. Known as a “graticule,” it had horizontal divisions with intermediate ticks that the technician could use for ascertaining waveform amplitude on the Y-axis and time intervals on the X-axis. Nowadays the physical graticule has been replaced by an electronic image on the screen, which can be scaled and moved by manipulating front-panel controls, and these lines can be used by the technician to estimate waveform parameters, such as peak-to-peak voltage.

However, much greater accuracy can be achieved by using the “Cursors” function. To do this using the Fluke 190-502 ScopeMeter, press the “Cursor button” (right below “F4”) after the instrument has been turned on. The “Cursor” menu appears below the display. “F1” permits the user to toggle cursor configurations. For example, the two vertical lines cause the cursors, signified by black lines in the display, to intersect the X-axis so that time is measured. Notice that time (in milliseconds or another appropriate unit) is displayed in the information bar above the display. Similarly, toggling to the two horizontal lines causes the cursors to intersect the Y-axis, displaying millivolts or volts. Pressing “F2” shifts to the “Move” function, allowing the user to move either the top or bottom cursor. When this is done, the value in the information bar above the display changes. The real usefulness of “Cursors” comes when a signal is accessed and its waveform is displayed. The cursors can be moved to align with the peaks or any intermediate wave features, and the value will be displayed. This is far more accurate than estimating these parameters by counting divisions and ticks on the graticule.

These exercises should give you a good feel for the way the ScopeMeter works. Now, we’ll see how the instrument can be used to troubleshoot a malfunctioning electrical system. First, if you are involved in development or maintenance of motorized or other electrical equipment, it is recommended you take electrical measurements and capture waveforms while the equipment is operating normally, prior to failure or irregular performance. This is best done periodically. If a motor or the overall installation is unusually costly or downtime is unacceptable, it may be worthwhile to keep a log with saved oscilloscope screenshots so harmful trends can be spotted before catastrophic failure occurs.

The purpose of VFDs is to control the speed and direction of motors. Objects of special interest in a large VFD are the three- phase power input, measured at the disconnect; the power output measured at the VFD output and at the motor terminals; and, between the rectifier (which powers the DC bus) and inverter, the DC bus. At the power input, the AC supply should show well- formed sine waves without clipping, distortion or phase imbalance.

The DC bus inside the VFD should show smooth, ripple-free horizontal lines of equal amplitude. The output should consist of well-formed pulses with instantaneous rise and fall times. Large spikes at the decay are a bad sign. It should be possible to see and measure variation in the duty cycle as the motor is made to speed, slow or change torque. If the electrical parameters are less than ideal (as described above), the system may be performing satisfactorily, but it is likely the motor will run hot and fail prematurely.

In a VFD, downstream from the DC bus, the pulse-width modulation inverter controls voltage and frequency fed to the motor’s input terminals. This takes place because of the semiconductor switch behavior. At the input end, diodes create a DC buffer that is needed for the switching inverter. The DC voltage is 1.414 times the AC input voltage. The capacitor serves as a filter to minimize ripple at the DC bus. The capacitor and/or one or more diodes may fail, altering the characteristics of the DC voltage, so this is an essential target for an oscilloscope investigation.

In the inverter section, control is provided by insulated gate bipolar transistors capable of supplying up to 500-hp motor loads. Taking these measurements is not for the fainthearted, and it calls for extreme caution regarding shock and arc-flash hazards.

To examine voltage on the DC bus, the oscilloscope is used with DC coupling to measure the absolute value. Use AC coupling to see ripple. Since voltage on the DC bus is 1.414 times the AC root-mean-square value, for a 480-VAC drive, the DC bus should measure 678 V. If the amount is low, the drive will be tripping out. If that is the case, the mains input voltage may be low or distorted by clipping, or there may be a line problem. If successive peaks in the DC bus ripple have different levels, a rectifier diode may be bad. Excessive ripple voltage points to a bad capacitor or mismatch between VFD and motor. Even a small amount of ripple in a VFD DC bus can prevent satisfactory operation.

A very big issue in VFD performance is in the wiring from the drive output to the motor terminals. There may be harmful harmonics and reflections caused by fast rise and fall times of the modulated pulse waveforms. If there is an impedance mismatch, a reflection peak can equal the DC bus voltage.

If the system was working properly and the trouble (as exhibited by motor overheating and tripping out) began abruptly, look for kinking or damage to the transmission line. If the system never worked following installation, it may be necessary to increase the conductor size or, if possible, shorten the run. Also, as always in such matters, check all terminations.

Many technicians prefer to use a handheld, battery-operated oscilloscope, rather than the line-powered bench model, in industrial settings. Besides being more portable and ruggedized to withstand moisture and rough handling, it is immune to the hazards of improper connection to a voltage referenced to and floating above ground reference. Also, the capital investment is lower.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on p. 147 of this issue.

♦ When is a handheld oscilloscope preferable to the bench model?

♦ What is the value of the “Math” function?

♦ Why are precautions needed in working with a VFD?

♦ What is the purpose of the DC bus in a VFD?

♦ What are symptoms that indicate a capacitor problem in a VFD?

Get more of Elevator World. Sign up for our free e-newsletter.