Stannah Group chairman turns to family company, expert team to design perfect elevator for his home, a 17th-century English estate.

Headquartered in Andover, U.K., and now in the hands of a fifth generation, home lift company Stannah Group respects history. The company is experienced in developing bespoke home elevators for esteemed properties, such as the Burghley House in Stamford, U.K., built in the 1500s, and the 1750s-era Dumfries House in Ayrshire, Scotland. So, it was a no brainer when Stannah Co-Chairman Brian Stannah and his wife, Jenny, were looking to make their four-story home, built in 1685, more accessible as they approach their golden years, that they looked to the family company. Recalled Brian Stannah:

“My daily journey down the stairs with the tea tray began a thought process that led me to thinking about moving ourselves and goods around the house in later years. We knew we wished to remain in our home, but the challenges that old age inevitably bring might force us to leave. We decided to investigate how we could future-proof our home so we could welcome our three sons and 11 grandchildren for many years to come.”

That “future proofing” took approximately nine months and involved bringing in the expertise of architect Peter Thompson and structural engineer John S. Ellard. Stannah is a major producer of stairlifts, but Brian and Jenny Stannah’s home called for a more intricate and permanent solution. Initially, the team leaned toward building an enclosed lift on the home’s exterior. However, this idea was abandoned due to the fact it would mar the structure’s historical stature and, in turn, its status as a Grade II-listed historic property – which signifies architectural and historical significance. An elevator that would travel between cellar and attic, a distance of approximately 10.5 m was chosen, instead. Recalled Thompson:

“The initial call from Brian was a challenging proposition, but we were determined to find the right solution for both the house and its occupants. Building an external lift is often a solution, but not in this case. The aim of the installation was to provide level access to all areas of the house, and it simply couldn’t be achieved unless the lift traveled through the house. To include both the cellar and attic meant choosing the pathway for the shaft and then reconfiguring the layout of some rooms to make this possible. Finally, the footprint of the lift was dictated by the space available, and, of course, Stannah was able to supply a bespoke product.”

The Cellar

This area of the house posed the first and biggest problem. The cellar has an arched, vaulted ceiling, so creating an aperture for a lift shaft was no mean feat. Finding a pathway through the house that would provide a plumb line resulted in the lift sitting in the center of the cellar, in turn breaching the center of the arch.

Brian Stannah observed the largest obstacle, by far, was the structural engineering needed to support the cellar and house before the lift could be installed. Structural engineer John S. Ellard of Graham Garner & Partners Ltd. reiterated that there was no room for error. The first task was to insert steel rods into the curved wall and ceiling to permanently strengthen the arch. Then, the shaft was constructed almost to the reinforced aperture before workers carefully cut through the ceiling. At cellar level and the first floor, the lift has a single entry.

The Ground and First Floors

On the ground floor, the house has several changes in level. To ensure level access, the lift has two entries: one (currently in use) via a raised area from hallway to kitchen and another on the opposite side of the car opening into a small utility area redesigned to accommodate the shaft. This entry provides level access into the hallway.

On the first floor, the shaft prompted a reconfiguration of two back-to-back bathrooms. By making both smaller, an additional landing space was created, providing access to both the lift and a study beyond.

The Attic

Here, the Stannahs reluctantly relinquished some of the space in a generous room housing a piano and library, and, for many years, a snooker table. At this level, the shaft had to break through the original, sloping roofline, which created concern for all involved. However, the roofline features several dormer windows, and the lift shaft echoes their shape and blends unobtrusively with the whole.

The Lift

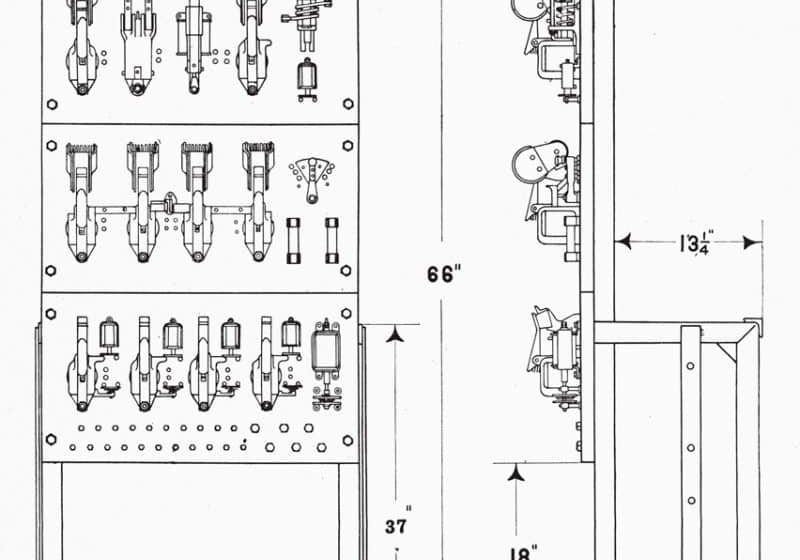

The unit selected for this installation was the MidiLift XL Plus, a space-efficient, low-usage passenger lift. Its machine-room-less traction drive ensures quiet operation and energy-efficiency, which, combined with minimal load-bearing requirements, make it ideal for a residence.

The lift was manufactured by Stannah Lifts in Andover, U.K., to bespoke specifications dictated by the home’s restrictions. Among notable features are custom, powered fire doors for each landing, finished to match existing doors. As standard, the model includes:

- A 900-mm clear opening at each entrance

- A two-tone arrival chime at each landing

- A surface-mounted call station with LED display and push-button control

- A key switch to isolate the lift at main floor

- Emergency lighting and an alarm with backup battery

- Energy-efficient LED cabin lighting

- Automatic button controls

- Audible and visual notification of floor level and travel direction

- A two-way intercom for emergencies

- A full-height light curtain on entrance edges

- An automatic emergency-lowering feature

Epilogue: Flood Prompts Adjustments

In February 2014, many parts of the U.K. experienced unprecedented rainfall. Dorset, where the Stannah home is located, did not escape unscathed. The cellar and a shallow pit beneath the car that provided access were both flooded, rendering the lift unusable. Brian Stannah recalls:

“We had just congratulated ourselves on a job well executed when the flood happened. We have lived in the house for 20 years, experiencing severe weather but never anything like this. We could not risk it happening again, so we had to take action.”

It was decided to raise the lift’s stopping position in the cellar by filling in the shallow pit, lifting the floor of the car and reducing the entry-door height. The lift now has a shallow step and a ramp for level entry as an alternative. The ancient floor of the cellar is covered in original clay tiles, which were lifted and reinstated to complete the work.

The end result is ideal, according to Brian Stannah, who elaborates:

“Everyone involved did a terrific job. Our home now has the invaluable, discrete addition of a lift that will help us in the future. For the moment, we tend to take the stairs and send items we can avoid carrying in the lift. We look at it as an investment for our later years.”

Get more of Elevator World. Sign up for our free e-newsletter.