Is It Working?

Dec 1, 2014

A different approach to elevator monitoring and why it is a worthwhile expense for owners, saving them money and downtime, and preserving quality

Building owners, maintenance companies, construction companies and construction rental companies often have various reasons for not wanting remote monitoring. With spying and tracking being big current events topics, the general public is leery of anyone watching them. However, anyone with an elevator does want to know, “Is my elevator working?” What exactly does this mean? Knowing that the unit is drawing power, and its motor and controller are running do not necessarily mean the elevator is working.

At an Elevator U conference, your authors asked the audience how they know the elevator is working. The experts gave us the following answers (A) to the questions (Q):

- Q: Does the elevator move?

- A: I can feel it move; I can hear it; I can see the position indicator change; my customers aren’t complaining.

- Q: Does the door open?

- A: I can see the door open; I can hear it; I can get out of the elevator; my customers aren’t complaining.

- Q: Is it going to the right floor?

- A: I watch the position indicator; I read the placards on the landing; I note the time of the trip.

- Q: Is it comfortable?

- A: I can feel it vibrate; it is very noisy; I’m getting sick; my customers are getting sick.

- Q: Is it safe?

- A: I felt it stop abruptly; It hasn’t trapped anyone; I didn’t get an emergency call; I didn’t hear the alarm; the lawyers haven’t called; my customers haven’t moved out yet.

- Q: Is it efficient?

- A: I am getting a lot of callbacks; the machine room is too hot; my maintenance costs are high; riders are complaining because it is slow; the power consumption is high.

The interesting thing about their answers is that most of these methods are based on human perception. Indeed, the best real-time diagnostic tool for elevators – the elevator operator – is rarely used anymore.

Mimicking Perception

There are many different kinds of elevators in use today: old, new, traction, hydraulic, rack-and-pinion, freight, construction, etc. They may have different controls, and many are obsolete. However, they all have one thing in common — performance. Elevator performance is really a measure of how well the elevator runs, compared to the way it was designed to run. The National Elevator Industry, Inc. (NEII®) publishes Building Transportation Standards and Guidelines, NEII-1, which identifies 52 criteria for elevator performance. Most of these are measured by human inspectors, with or without the aid of test equipment. Some of these performance criteria can be determined from the control, but many can only be measured by riding in the car.

It would be very difficult to build a machine that had the same senses as a human elevator operator, but this is not necessary. One way to accomplish this is to use independent sensors in the car to measure the physical properties that contribute to human perception. One way to mimic the “feel” of the elevator is with an accelerometer in the car. Acceleration in the vertical direction can tell a lot about the performance of the elevator. At the basic level, it can indicate what the rider feels when the elevator starts moving and when it stops. Examining the instantaneous change in the acceleration is a measure of “jerk,” or how smooth the trip is. Measuring the acceleration along the x and y axes can tell how much sway the elevator is exhibiting as it moves in the hoistway.

We can determine the speed of the elevator by integrating vertical acceleration over time. Noting when the acceleration begins and when the deceleration ends, we can determine the length of the trip the elevator just made. The distance the elevator traveled can be determined by integrating the speed over time. Alternatively, an altimeter in the car can be used to refine the distance traveled and determine the location of the elevator car in the hoistway.

Other sensors can tell us about various conditions of the elevator. Temperature sensors and electrical-current sensors can indicate how the motor and drive are functioning. Magnetic sensors can tell if relays or the brake are energized. A simple camera that identifies colors can determine the position of the door.

A well-known rule in manufacturing is that the instruments used for making a product should not be used to test the product. Ideally, the equipment used to monitor an elevator should be independent of the elevator itself. These can be devices permanently installed on the elevator car to continuously record and evaluate data. Or, they can be portable devices used intermittently, either on a schedule and/or as needed. The data should be consistent for all types of elevators.

Analytics

According to Wikipedia, “Analytics is the discovery and communication of meaningful patterns in data. . . . Analytics relies on the simultaneous application of statistics, computer programming and operations research to quantify performance.”[1] Elevator analytics uses data from multiple sources (often sensors), along with statistics, to determine how well an elevator is running. This can be done immediately while the elevator is operating or over a longer period of time (days to years).

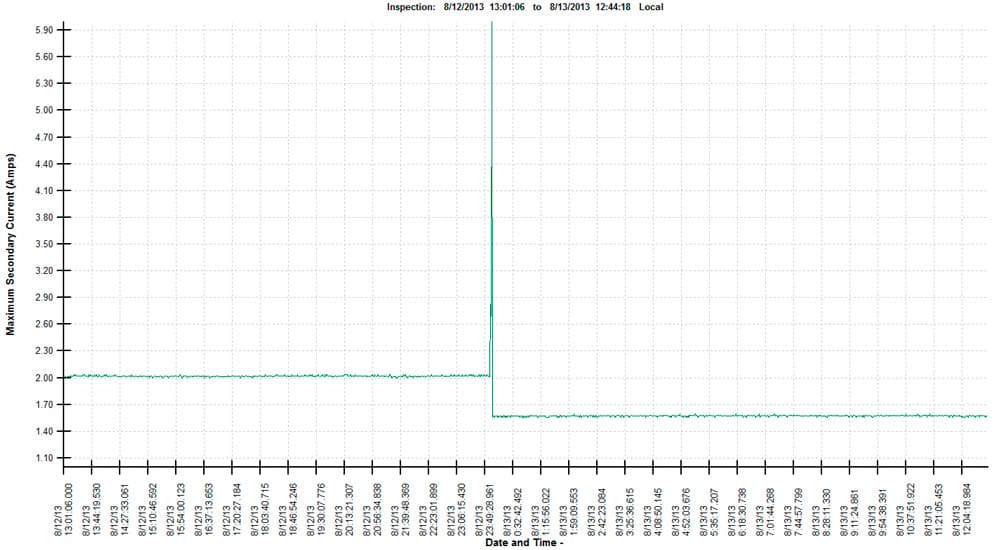

The raw data from the sensors tell us about the current conditions of the elevator. Using analytics tells us a more complete story of the elevator. For example, we can measure the current going to the elevator car for lights, phone, etc. This can be used to help determine the instantaneous energy used by the elevator. However, if we look at the car current over time, we can determine if there is a problem (Figure 1). Here, the normal current to the car is 2 amps, but it jumped to 6 amps, then dropped to 1.5 amps. Clearly, something happened to cause this behavior. (The fan motor seized, then burned out.) By setting the limits for the car current to expect the 2-amp draw, an alert could be issued to warn of a problem.

A key element of analytics is to use a model of the process to be evaluated. In this case, the process is moving an elevator from floor to floor to transport passengers. Fortunately, except maybe for construction elevators, the behavior of the elevator should be consistent – the door closes, the elevator moves, the door opens. There are more details of this behavior, but the model is relatively simple. Deviations from the model often rely on measuring times (door opening, door closing, etc.) and statistically comparing them to the “normal” behavior of the elevator. There are also deviations from the behavior, such as when an elevator parks and the door does not open after moving. Other parameters are considered in the model, such as the motor current, hydraulic pressure and machine-room temperature. The model of the elevator’s behavior does not need to be highly accurate; often, it is sufficient to just notice how the data change over time.

It would be prohibitive to ask the user of an analytical system to specify all of an elevator’s details. To minimize the user’s involvement, building the model often involves using heuristics (“rules of thumb”), such as, “The elevator is not used very much on weekends, so the idle times will be long.” Machine learning can also be used to build the model. For example, the diagnostic system can learn the layout of the building (number and spacing of landings, etc.) as the elevator runs. A “training” period may be used to determine the statistics of the model of a good elevator.

Risk Management

No machines, including elevators, will run perfectly all the time. As long as the elevator is available, safe and comfortable, we can accept imperfection. The model used to evaluate the elevator’s performance should take into account factors such as age, technology and criticality. In other words, the model should manage the risks of operating the elevator. These risks are not consistent for every person. There are obvious risks to the safety of the rider, but we will instead look at the monetary risks to people who own, operate and maintain elevators.

Modernization Decision

The decision of if and when to modernize an elevator is full of monetary risks. Doing too much or too little can have serious budgetary consequences. Modernizing an elevator may cost more than US$250,000 in a class-A office building.[2] Knowing how an elevator is behaving is important when deciding between a repair (which does not affect the code applicable to the system) and a complete modernization that may be subject to a newer code.

One application in which analytics are being used to facilitate the decision process is at a university with 200 elevators of various types and ages. Given a fixed budget for modernization, it is important to prioritize the candidate elevators. A portable elevator diagnostic system can be used to evaluate and compare the operation of these elevators. It can be installed in each elevator for a period of a few months, spanning periods of varying traffic densities.

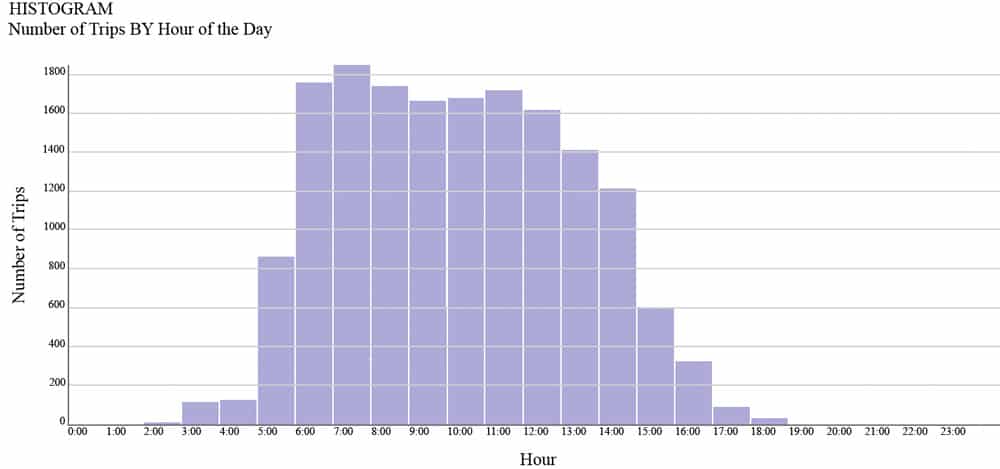

Several factors affect the modernization decision. The total usage of the elevator and its daily distribution of trips relative to those of other elevators in a building should be considered. Figure 2 shows the distribution of trips by time of day. This elevator is used primarily from 7:00 a.m. to 4:00 p.m. and makes approximately 350 trips per day. This is a lightly used elevator, but it is the only elevator in the building, increasing its priority.

Energy usage is also an important consideration in the modernization decision. Figure 3 compares the energy used by five traction elevators in one day. Elevators 3-5 have motor-generator sets, which use proportionally more energy when idle than they do when moving.

There are other factors that contribute to the modernization decision, such as elevator age, parts availability, downtime and repair frequency. But, being able to compare the performance of different candidate elevators will reduce the monetary risk of any decision.

Maintenance Support

There are monetary risks in elevator maintenance for both the building owner and maintenance company. Both parties have the same objective of keeping the elevator running in a safe and cost-effective manner. Building owners face the risk of losing tenant income and repair costs. Maintenance companies with comprehensive service contracts risk unnecessary service costs.

Elevator analytics can be used to reduce risk by helping to understand the behavior of an elevator during the service period and before the contract is written. Using a small, portable performance analyzer prior to proposing a contract can help the maintenance company understand what it is getting into. Once the contract has started, a remote performance analyzer (Figure 4) can provide a complete history of every elevator trip.

Knowing what is happening to an elevator prior to a service call can determine the severity of a problem. This will facilitate repair scheduling, ensure that the right personnel are dispatched with the needed parts and minimize downtime.

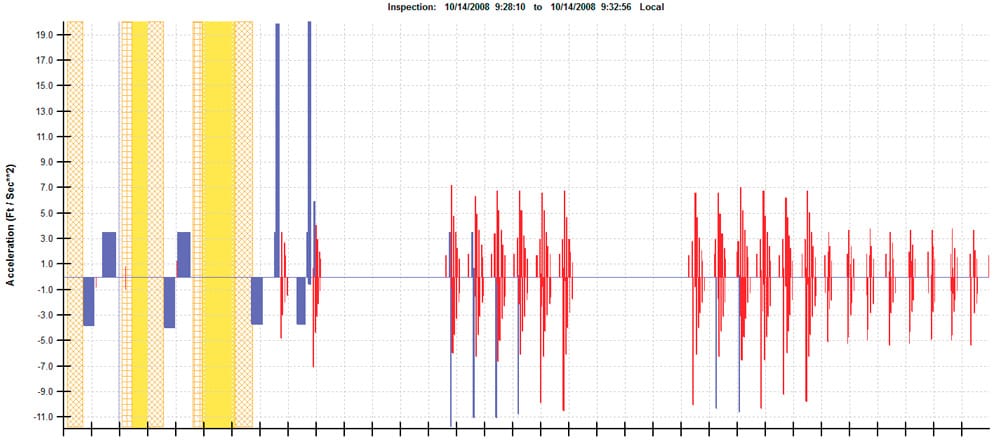

Elevator analytics are being used to diagnose difficult problems. Failures are rarely isolated events, sometimes happening for days before they are reported. It is often the case that the elevator behaves normally while the technician is on site. This was the case shown in Figure 5, where the elevator made two normal down trips (at left). Then, it was making another down trip, when it stopped abruptly with a deceleration of 20 fps2. The elevator then restarted by itself and abruptly stopped again. After this, it began to start and stop abruptly every 7 s. This continued for 8 min.

When the problem was reported and the technician arrived, the problem was found to be due to a sensor that detected stretching of the ropes. Every time the elevator started to move, it stretched the ropes slightly, which caused the sensor to trigger a switch to shut down the elevator. Examining the data showed that the behavior occurred several times in the preceding week but only when the elevator was empty and parking. If the limit on the acceleration had been set, the monitor would have alerted the maintenance company when the problem started.

Construction Rentals

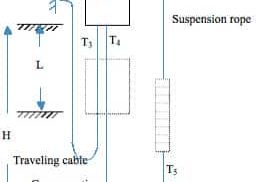

Nowhere is there more monetary risk than in construction elevator rentals. These machines are rack-and-pinion elevators (Figure 6) that have characteristics that make them unlike other elevators: they are manually operated, and the elevator owner has no control over their operation; they are subjected to heavy loads and bad weather conditions; they are often located hundreds or thousands of miles from the owner’s office, making maintenance calls expensive; and they are disassembled and reassembled when moved from job to job.

The downturn in the construction industry due to the recession made the rental industry highly price competitive. Controlling costs is extremely important, and with construction companies under tight schedule constraints, there was increased pressure to reduce downtime. These machines are still elevators, and a diagnostic system must answer the same “Is it working?” questions. Safety and reliability are just as important for these elevators as for elevators in buildings.

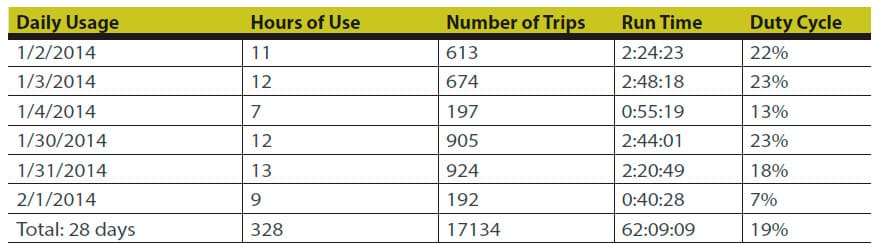

How and when the elevator is used affects the owner’s profitability. Construction elevators are usually rented for a fixed number of hours per month and certain times of the day. The owner can tell if the renter is abiding by the contract by analyzing the elevator’s usage pattern. In this example, the elevator was rented for 220 hr. per month and 8 hr. per day. However, the data show that the elevator was used 9-16 hours per day (Figure 7) and for a monthly total of 328 hours (Figure 8).

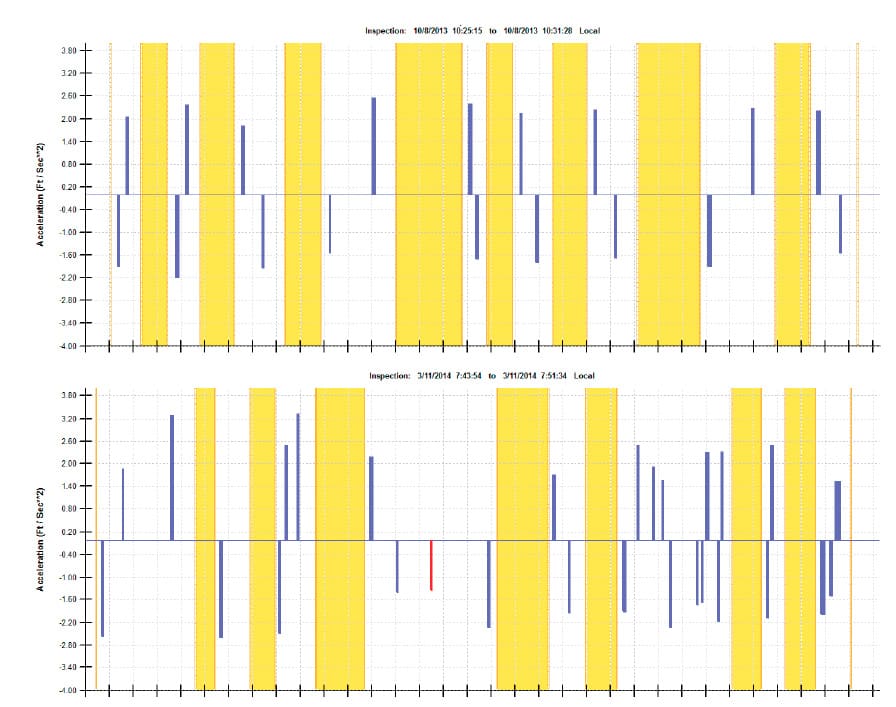

How customers use the elevator affects the owner’s bottom line (usage, wear and tear, etc.). Every time a mechanic returns to the construction site, the elevator owner loses profit. Figure 9 shows how the smoothness of an elevator changed over time. In both graphs, the operator was making single trips between the openings and closings of the door. When first installed, a single acceleration/deceleration pair was recorded during these times. After six months of use, the accelerometer recorded multiple motions. In the latter case, the elevator was jerking significantly when it should have moved smoothly. This may indicate that the elevator needed lubrication, was lifting unbalanced loads or just wearing out. Continued operation in such a case could result in failure or repairs.

Will My Elevator Work Tomorrow?

The ultimate goal of elevator analytics is to predict the behavior of an elevator. This will have a profound effect on the cost and risk associated with owning an elevator. Knowing how and why the performance of an elevator changes over time is the first step to recognizing its behavior patterns.

Creating a predictive system requires a significant amount of data. In addition to usage data, information about any maintenance and repairs performed on the elevator is needed. Before failures can be predicted, it is necessary to have a history of when they occur. It is also important to have information about how long parts last, how much it costs to perform repairs, etc. Automatically collecting the data about the elevator’s performance is easy. Painlessly getting the other information is the hard part.

Figure 1: The current to an elevator car over a period of approximately 24 hours

Figure 2: HISTOGRAM Number of Trips By Hour of the Day

Figure 3: Traction elevator energy usage

Figure 5: Elevator abnormal accelerations and decelerations, shown by red bars; blue bars show normal acceleration and deceleration. The yellow areas indicate that the door is open.

Figure 6: A rack-and-pinion construction elevator rental

Figure 7: Monthly rental use by hour of the day

Figure 8: Total monthly usage (not including the period between January 4 and January 30)

Figure 9: (top to bottom) Smooth operation when installed; jittery operation after six months

References

[1] Wikipedia. “Analytics” (en.wikipedia.org/wiki/Analytics).

[2] Collins, Jeff. “The Hidden Details of Modernization,” ELEVATOR WORLD, September 2014.

Get more of Elevator World. Sign up for our free e-newsletter.