Jerk-Free Takeoff With Pulsed Pre-Torque Drive Software

Oct 1, 2017

New method and system for reducing rollback senses needed pre-torque before the mechanical brake is released, resulting in a smooth start.

by Peter Stipan, Garry Anderson and John Backman

Magnetek took up the challenge of creating the smoothest elevator ride possible, despite the fact that every run of an elevator car has a unique load. In our new control method, our permanent-magnet AC (PMAC) elevator drive determines preoperation torque (pre-torque) needed for an elevator motor before the brake is opened.

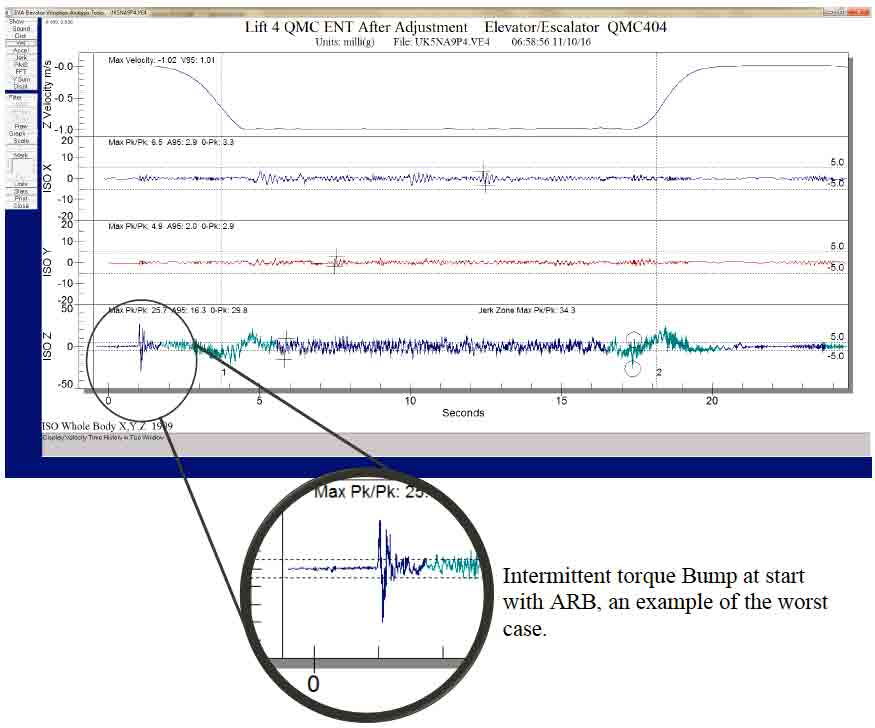

In November 2016, Magnetek visited a U.K. medical center where a consultant specified aggressive acceleration and deceleration for fast floor-to-floor travel times. While Magnetek’s drive met these requested times, the ride quality was less than ideal, so the travel time was slowed down by 2 s. Using Magnetek’s standard anti-rollback (ARB) technique, at this reduced (yet still aggressive) travel time, there was no rollback (when the elevator rolls back on the start of a run); however, there was a slight torque bump (noticeable shudder either at start or stop). This torque bump was more pronounced at the top of the shaft (when the brake is released). We felt we needed to understand this condition and develop a means of eliminating the undesirable torque bump at faster travel times, while eliminating rollback. Further, we wanted to ensure any solution we developed did not require an external pre-torque device, such as a load weighing system.

Background

In a gearless traction machine, five to eight lengths of wire ropes are attached to the top of the elevator cab and wrapped over a drive sheave in special grooves. The drive sheave is directly mounted to the shaft of the gearless elevator machine (motor). The other ends of the cables are attached to a counterweight that moves in the hoistway on its own guide rails. The combined weight of the elevator car and the counterweight presses the cables into the grooves on the drive sheave, providing the necessary traction as the sheave turns.

To reduce the load on the motor, the counterweight is typically calculated to match the weight of the car and a half-load of passengers. As the car rises, the counterweight descends, balancing the load. This reduces energy consumption, because the motor is generally required to lift no more than the weight of half a carload at any time. The electric motor that runs the elevator must be powerful enough to turn this drive sheave at 50–200 rpm to move the elevator at the proper floor-to-floor speeds.

A brake is used in conjunction with the motor to provide further safety in the system and reduce strain on the motor. In such systems, the brake is able to hold the sheave, cables, cab and counterweight stationary. When a call for the elevator to move to another floor is provided from the car controller, the AC drive is enabled to run. The brake is commanded to release before motion is initiated. During this transition from a stationary to moving elevator car, a proper level of torque must be provided by the motor as the brake is disengaged (or “picked”). The motor then continues to move the cab according to the floor call from the car controller.

In certain circumstances, which may depend on the system configurations and weights involved, the period between disengagement of the brake and activation of the motor may cause a brief rollback of the elevator cab. This crossover period may also cause auditory noises and/or noticeable vibrations when the motor must hold the car to keep it stationary. The dynamics of this situation changes with every floor call, as the load of an elevator changes with each stop. A rollback condition may cause uneasiness for car occupants and/or disturbances for building occupants nearby and is, therefore, undesirable. An improved counterbalancing system in which one or more of the drawbacks may be minimized in such circumstances is needed.

When a lifting device is engaged for motion, a fixed amount of weight may be established for the individual run or motion profile. At this point, the drive may be made ready to operate (or “enabled”). A pre-torque direction and magnitude may be determined between the time an enable signal is commanded by the elevator car controller and the brake is released to begin motion. This may be done so the loading being held by the brake may be transferred to the motor before the brake is released, resulting in a smooth transition.

In Magnetek’s analysis of this transition period, a pulse of torque may be applied to the motor, and any corresponding movement can be fed back to the drive prior to picking the brake. An increasing level of torque pulses may be applied to the motor in the positive, then the negative direction, while monitoring for movement. If there is backlash between the motor shaft and brake, such that the backlash is taken up and motion is sensed beyond a torque level, it is determined to be the level of torque required to maintain the offset load when the brake is subsequently released. This may be done in both directions, because the load offset is load dependent on every run.

The application of torque before the brake is released may take up a load offset and avoid an audible and/or vibrational transient, which may ordinarily occur. In other words, a sheave and motor may be pulled one way by a load, and a small movement may be sensed. A smooth transition from stationary to run will occur if the motor produces a torque equal to or higher than (but in the opposite direction) to the load just as the brake is picked.

Moreover, varying a magnitude of the pre-torque pulse may allow for determining a magnitude for the pre-torque command, in addition to a direction, regardless of elevator car loading at the start of a run. With both direction and magnitude of torque determined, the operation of the counterbalancing system can begin, while providing a smooth start.

Solution

From the patent details, “Method and Apparatus for Controlling Motion in a Counterbalancing System,” invented by two of your authors, Garry Anderson and John Backman; and Mark Kobiske and Ed Butte, Magnetek determines a pre-torque direction and magnitude during brake engagement prior to each elevator run. This Pulsed Pre-Torque (PPT™) function applies this measured pre-torque in the commanded rotational direction prior to brake disengagement.

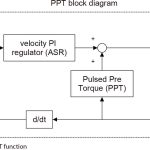

In this technique, Magnetek PMAC drives use small amounts of feedback, as seen by a shaft mounted encoder interpolated to much higher pulses per revolution. With that feedback, incremental movements (movements smaller than a passenger in the car can detect) can be used to properly provide pre-torque feedback to the PMAC Drive. The PPT function operates at the start of the elevator run before the brake is picked and generates an offset torque that estimates the elevator load. Consistent with our stated objective, the control function operates without the use of a load-weighing system. Synchronization with the brake must be built into the system so this pre-torque value can be applied prior to the brake being opened (Figure 1).

Validation

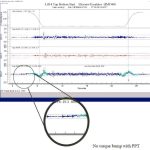

We returned to the medical-center customer in March 2017 to find that local adjusters had set an even more aggressive acceleration/deceleration profile than originally specified. These elevator-drive adjustments were made after our first visit, and, as anticipated, while the ride was acceptable, it was not ideal. We then introduced our new firmware employing the PPT function. This significantly improved ARB performance (Figures 2 and 3). These ride-quality measurement plots show elevator vibration analysis before and after implementing the PPT function.

Conclusion

The simplicity of using the PPT function is nearly as beneficial as the resulting improvement in ride quality. To use the PPT function, Magnetek disables the traditional ARB function, while setting the PPT parameter to “Enable.” This is a big advantage over traditional ARB functions, in which a series of run and stop commands are needed to adjust ARB levels. Further, the PPT function eliminates the cost, setup and maintenance of external load-weighing devices. There are no settings to configure; only the PPT function needs to be enabled. Most importantly, the PPT function pre-torque calculation did not translate to vibration or sensation underfoot. When the brake is released, there is no rollback, torque bump, or audible sound of the brake releasing — just a transition from stationary car to smooth acceleration.

Whether modernizing or installing a new PMAC-equipped elevator, the PPT function reduces rollback in a counterbalancing system as a holding brake is released. Since our first field installation, several Magnetek HPV® 900 Series 2 PMAC drive customers have enjoyed its simple function, which requires no setup or tuning.

- Figure-1

- Figure 2: Ride quality plot 1: ARB performance (October 11, 2016)

- Figure 3: Ride quality plot 2: ARB performance (August 3, 2017)

- Figure 4: A Magnetek HPV 900 Series 2 PMAC drive

Get more of Elevator World. Sign up for our free e-newsletter.