Maintenance, the Correct Approach to Raise the Quality

Sep 1, 2020

Proper maintenance improves equipment quality and, thus, the industry’s reputation.

This article was first presented at the 2019 International Elevator & Escalator Symposium in Las Vegas. For more information on December 6-7, 2021’s event in Amsterdam and to participate, visit www.elevatorsymposium.org.

Many global maintenance organizations have developed various methods by which to efficiently maintain their portfolio. This efficiency is usually based on a balance between time spent per unit and components adjusted/checked per maintenance interval. However, do these efficient maintenance visits really benefit clients, too?

Wear is compounded on every moving mechanical component, current-carrying electrical component and electricaly controlled electromechanical component. This limits the components’ lifespans, which deteriorate quicker as they suffer more wear. The wearing out of mechanical parts is caused by mechanical forces like friction, torque forces, direct forces or environmental conditions like corrosion, humidity and temperature differences, causing the materials to weaken. Wearing out of electrical parts, on the other hand, is caused by effects of mechanical forces that act on physical parts of such electromechanical components like relays and contactors. Vibrations generated by the system cause loosening of fixing screws, cracking of soldiering points, loosening of cables from terminals, etc. The malfunction of integrated electronic elements on electronic boards like capacitors, central processing units and insulated-gate bipolar transistors weaken the materials of electronic components. This is because of charge/discharge limits; heat generated by electricity; fading of data inside integral chips, etc.; or the aforementioned environmental conditions.

The basic tasks of a maintenance service involve reducing and slowing down wear. This will lower replacement costs for the owner and keep the devices functional. These goals are achieved by keeping the components clean/neat, adjusting the devices or components properly and continuously monitoring the system in terms of functioning of both the electrical and mechanical components. However, maintenance organizations tend to complete these tasks not in every maintenance interval, but in a sum of maintenance intervals, which brings the issue to the table of what happens between the completed maintenance cycle.

Maintenance quality greatly affects the lifespan of components and rates of mean time between call-backs (MTBC). And, the fact is, every installation has different circumstances, even in the same building.

This presentation will mention benefits/disadvantages of these maintenance methodologies and focus on wrong actions executed on maintenance intervals, as well as actions required but not executed at all on real-life project inspections and assisting ways to improve the quality of services for all related parties, resulting in longer lifespans and fewer breakdowns.

Introduction

One of the leading methods for modern maintenance operations is to follow a checklist for the units at hand for every kind of elevator and escalator in the portfolio of the service company. Service-providing companies use control lists to make the maintenance easy and efficient for their service staff. Items to be checked are explained in the maintenance instructions, as well as in various technical guides prepared according to hardware and installation types.

EN 13015 lists the scope of maintenance as:

- Lubrication

- Checks

- Passenger rescue operations

- Setting and adjustment

- Repair or replacement of worn-out components

The above tasks are executed in different forms of instructions by different vendors changing according to installation variations. Yet, the maintenance instructions may focus more on efficiency by unifying the instructions to be used globally, which, in the end, decreases the number of persons and/or time spent per unit for maintenance, benefiting the service company. Although this may seem like an adequate method to follow for these companies, the result for the product owners does not seem to be as brilliant.

Disadvantages of Unified Maintenance

As much as maintenance companies state they are focused on preventive maintenance, in practice, what we observe more is that they still go by the corrective maintenance methodologies. Thus, the intervention occurs after the faults happen, and root causes of the problems at frequent occasions are not addressed. One of the reasons preventive maintenance cannot be achieved is that the checklists and instructions used by companies are based on pure product knowledge, rather than environmental circumstances. The service company, planning to save time and labor, still provides the minimum sufficient maintenance by periodic visits, continuing to make the unit vulnerable against risk of breakdowns and early wearing out. This is mainly caused because of the following.

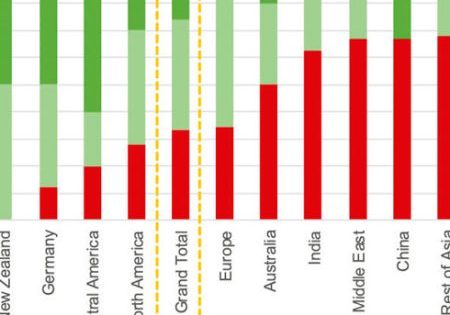

Service Visit Periods Not According to Use Intensity of the Unit

Elevators and escalators are maintained generally on equally divided monthly periodic field visits. However, the frequency of visits are not chosen according to field conditions, thus creating a risk for over-busy units. The reality is that installations are subjected to different severities of use and different levels of wearing out. Usual monthly maintenance visits are maybe sometimes too frequent for a rarely used carpark elevator but can also be too long a gap for an overused shopping-center elevator. Hence, the adjusted periods of visits are not an applied method by most service companies unless there is a specific demand from a client or consultant involved.

Regular Service Staff Not Allowed to Take Initiative About the Unusual Conditions

Maintenance staff, by training given and company culture injected, tend to comply with the instructions to the letter. Instructions not being comprehensive enough often causes regular maintenance staff to miss things that are obviously going to cause problems in the future. The service staff is obliged to go with the instructions and list that prevent them to “go beyond duty.” If not in that month’s modular checklist, a slightly late-responding brake shoe or a weird noise coming from the motor bearings will be neglected. Such issues are likely to cause a breakdown soon, yet neither the staff nor the staff manager can be blamed, as they are all doing what is commanded, while the client suffers. The technician is supposed to finish in a limited time, so taking the initiative to further investigate the installation and locate a problem is not encouraged.

The Weak Points of Installation Are Not Determined at Service Visits

Whether it is an escalator or elevator, any installation can be subjected to extreme circumstances that will cause a specific component to be used more severely than normal. The ground-floor call button of an elevator and the right-side handrail of an escalator (Figure 1) are examples of components that may wear out quicker than they should. When the maintenance is standard, these components are insufficiently adjusted, cleaned or examined. This is often a problem for a slightly nonstandard product and pushes the client to go hard on the service company, as the unit consumes more money than the one next to it with the same specifications. The increase in the cost of a specific unit’s maintenance rapidly gives the owner the idea that maintenance is insufficient. Yet, the maintenance organization, which is sometimes the distributer of a global manufacturer, is often too stubborn to accept that the global instructions it is following is not comprehensive enough to maintain the specific installations.

Generic Control Lists Cause Service Staff to Miss Important Defect Risks

Control lists used for the jobs are often not even specified according to lift models, especially at local service providers. This causes staff to not take any action of a growing problem like floor-reader adjustment at an elevator in which the stopping accuracy gets worse and worse, eventually causing the lift to stop at more than 1 cm, for example, out of level (Figure 2).

Another example is an overly greasy escalator step chain (Figure 3) in a dusty environment. If it is never cleaned, the chain can become elongated as the new oil is unable to ingress inside shackles. The excuse presented by the staff in such situations is often that the scope of maintenance, as well as the checklists, are already presented to the owner, and it does not include the cleaning of step chains. This insufficient methodology creates unhappy clients and long controversies between the relevant parties.

A Natural-Solution Approach

Where such problems occur frequently, it is often to our observation that “preventive maintenance” only works on units in the same projects or on the same models in different projects working in ideal conditions and are even “over maintained.” And, the service providers are never talking about the results on more problematic or riskier installations. The methods being applied must go beyond today’s still very-much-applied corrective-type maintenance. The key factors for effective preventive maintenance are as follows.

Time-Based Maintenance

The cycle of visits should be alterable according to status of the lift, e.g., since a summer residential elevator near a sea coast is rarely used in winter, monthly visits are more of a cost waste. The frequency of visits can change the lifecycles, as well as MTBC.

Risk-Based Maintenance

Other than checklist items of maintenance intervals, a component risk analysis must be used to develop a specific unit-focused service-checkpoint system. When the elevator or escalator is subjected to extreme conditions like heavy load, dust, humidity, vandalism, etc., a component risk analysis will allow service providers to focus on the major risk source for breakdowns and early wear-outs. The maintenance staff also must be trained about how to act with such an analysis or even form the analysis by themselves.

Service Staff Motivation

Although most technical people think that motivation of any service person is irrelevant to do their jobs, it is almost always our observation that units that are problem free are maintained by service people who personally try to achieve the same goals as the company. Therefore, existing quality systems in service providers encouraging the service staff to take more initiative for future risks is helpful for the application of preventive actions.

Specifying Maintenance Instructions

When service providers receive units that are not of their own manufacture, they tend to use the same instructions for every type of installation. However, missing or misleading information about the settings or insufficient documentation of the controls cause risk for breakdowns and increases the time it will take to put the unit back in service. Therefore, instructions for the maintained units must be far from generic lists and developed focusing on a specific type or model of elevator or escalator.

Conclusion

The object of today’s popular maintenance methodologies is to gain from a standpoint of time and money, while achieving a good maintenance regime in which success is measured by the number of call-backs and out-of-service times. However, when doing that, the systems applied force people to work like a software having the same algorithm for all kinds of uses. In the end, neither service providers nor owners benefit as much as they hope. To reach higher efficiency for not only the providers, but also for all parties, these systems must focus more on circumstances and persons. To do that, maintenances must get rid of static approaches and become more alterable and unit-focused, as these will allow the reputation of the industry, as a whole, to rise.

Get more of Elevator World. Sign up for our free e-newsletter.