One Stage Higher: Digital Rotary Encoders for Elevator Motors

May 1, 2012

This article examines various elements of elevator drive technology.

The technical demands placed on elevator technology have grown steadily in recent years. For example, conventional electrical drive technology with gear motors is increasingly replaced by torque drive systems, usually on the basis of permanent-magnet synchronous motors. For new construction and modernization projects, buyers have given favor to gearless elevator-motor designs.

Compact and maintenance-free designs, high power density and high energy efficiency play an important role for buyers when choosing between elevator systems. The desire to offer passenger convenience and improved quality is paired with a demand for innovative approaches in an efficient drive package that consists of a motor and control device. A basic package component is a feedback system for providing position values with which the motor’s actual shaft speed can be ascertained in the control unit and the commutation of the motor coil can follow the correct phase. Heidenhain’s rotary controllers contribute to this, coming into use in electronic drive control as commutation rotary encoders or absolute rotary encoders. In this application, absolute rotary encoders offer distinct benefits, especially for the use of rotary encoders with high resolution and serial transmission protocol (without additional incremental signals), such as Heidenhain’s ECN 1325 (Figure 1).

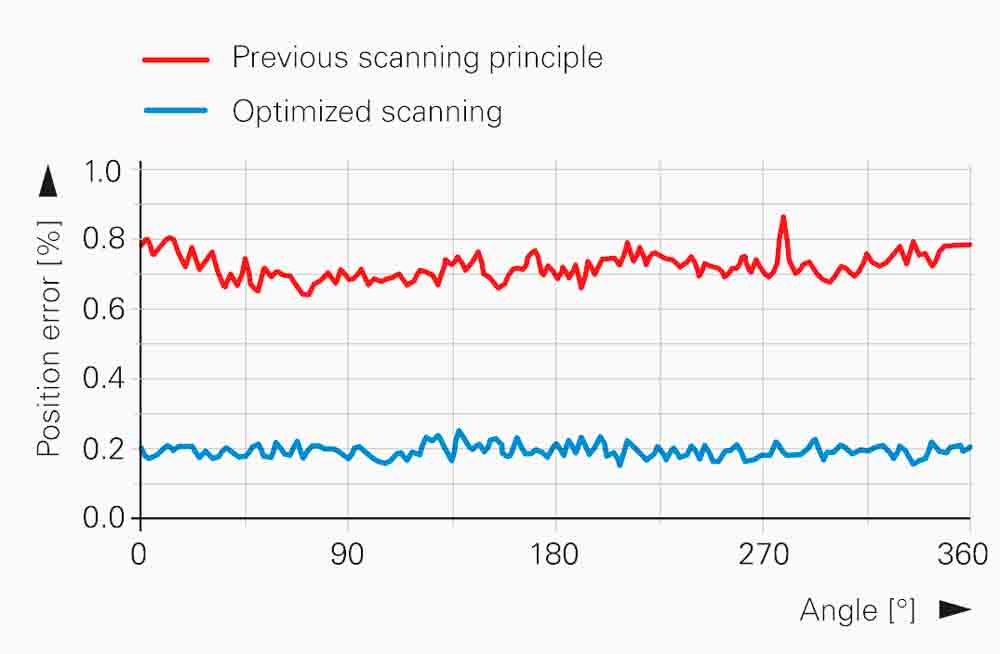

ECN 1325, with 25 bits per revolution and high accuracy values, provides the resolution required for a reactive drive control. These 33,554,432 distinguishable positions per revolution are generated through scanning, a graduation with 2,048 lines (Figure 2) and subsequent 14-bit interpolation of scanning signals in an application-specific integrated circuit developed for the task. This provides the drive controller with sufficient position data and, at a rate of 8 MHz, enough to permit a dynamic motor control and provide passengers with a quality ride.

The desired position value assignments (e.g., zeroing) over the EnDat 2.2 bidirectional serial interface enable the control unit to simply and efficiently provide commutation at the correct phase to the motor’s magnetic field for optimum torque. Thanks to the rotary encoder’s high resolution, it is possible to adapt this phase assignment to almost any number of motor pole pairs. This makes it possible to combine many different motor designs with only one rotary encoder version.

The bidirectional interface provides further advantages as the communications link between the motor and control unit. Aside from permitting position value transmission, it also allows the transmission of encoder-specific and motor-specific parameters that can be loaded from the electrically erasable programmable read-only memory area of the rotary encoder electronics into the control unit during the system boot phase, as well as for system configuration. Using this capability for factory preloading of relevant data reduces initial servicing and precludes input error during manual parameter input to the drive system.

The interface supports monitoring functions for achieving a high elevator availability rate. The rotary encoder electronics also make evaluation routines possible for temperature sensors. Besides the temperature sensor within it, the encoder also features a connection technology made to permit evaluation of the encoder’s circuit board of a temperature sensor on the motor coil and transmit the evaluation data over the EnDat 2.2 transmission protocol to higher-level electronics. In addition, diagnostic values generated in the encoder electronics in the form of evaluation numbers can be transferred over the interface for evaluation of the encoder’s functional reserve. If the value halves become critical, preventive measures can be taken to avoid unplanned maintenance downtime.

With routines to ensure high data transmission reliability based on a cyclic redundancy check and a variety of warning and alarm sources, ECN 1325 offers a high level of self-monitoring and diagnosis. Shaft speeds up to 15,000 rpm and a maximum operating temperature of 115°C emphasize its suitability for demanding electric-drive control tasks.

The new rotary encoder design with serial data transmission has proven itself against electromagnetic noise, with the noise resistance of bit information transmitted in push-pull mode (RS 485) classified as solid. Because scanning signals are interpolated in the rotary encoder, a single shielded cable with only six to eight wires is sufficient. ECN 1325’s power supply range of 3.6 to 4 V eliminates the need for remote sense lines, which track voltage attenuation over long cable lengths.

In contrast to the technological improvements in functionality and electrical characteristics of ECN 1325, such as the generation, processing and transmission of signals over rotary encoders with sine/cosine or transistor-transistor logic signals on commutation encoders, identical mechanical dimensions ensure mounting compatibility with other rotary encoder variants. Designed with a field-proven taper-shaft connection and expanding ring coupling, ECN 1325 is mechanically compatible for mounting with the more familiar ERN 1387, ERN 1326 and ECN 1313. This enables motor and elevator manufacturers to keep uniform motor designs, regardless of the control unit’s specific interface requirements. This ensures flexibility of the motor’s application. The modular versions mentioned previously (ExN 13xx) are also available as mountable versions (ExN 4xx) with an IP64 level of protection (EN 60529) and an attached cable to provide increased protection from dust and water.

ECN 1325 can optimize control loops and, with diagnostic capabilities derived from monitoring, can regulate preventive service and maintenance intervals. Mechanical compatibility with other electrical-interface variants from Heidenhain enables elevator-motor manufacturers to easily upgrade to a new generation of rotary encoders.

Get more of Elevator World. Sign up for our free e-newsletter.