For more than 20 years, Premier Elevator has dedicated its efforts to the fabrication and installation of elevator cabs and interiors. Operating in a 65,000-sq.-ft. precision-manufacturing plant in Oshawa, Canada, its diverse team fabricates traditional and specialized elevator cabs for the North American market. Clients have the option to purchase complete cabs, interior finishes only or have finishes installed by experienced and licensed mechanics. In addition to its full cabs and interiors, Premier offers a complete line of durable accessories.

From the start, Premier filled a niche in the custom elevator interior market. At the time, it worked predominantly on higher-end, exclusive elevator interiors. Today, it has expanded its offering to provide various elevator cabs, interiors and doors for a range of projects, including basic housing-project elevators to high-end triple-A building cab interiors, including a full line of glass cabs and entrances, along with large hospital cars.

In addition to serving the commercial and public sectors, there is a growing demand for its work in the residential market. This demand comes from both increasing numbers of residential high rises, to more private homeowners having elevator cabs installed in their personal residences.

Premier operates its own wood, metal and finishing shops on site. In addition, it owns a glass company, fabricates its lighting systems and manufactures protection pads. There is little reliance on outside vendors, except for specific materials. Premier currently employs more than 75 people. “We continue to grow. We are one of the largest custom elevator-cab companies in North America,” Tom Rennick, director of Marketing and Business Development at Premier, said. The company has the craftsmen and engineering to be able to pull together all required elements of an elevator cab within its own facility, which helps keep costs down.

With machine-room-less elevators playing a large role in today’s market, companies are continuing to look at ways to reduce weight and increase life expectancy and durability. Premier provides materials and engineering solutions to deal with weight issues on both new and modernized applications.

There are some features that cannot be eliminated from an elevator; some are mandatory, while others are logical. Handrails are required for safety and accessibility, while affording a protective bumper to the walls. Mirrors make spaces seem larger, and walls can look endless with them strategically placed in the corners of cabins or they can provide security features to let someone see inside the elevator before entering.

One of the most overlooked elements in elevator designs is lighting. Without light, cab interiors are conceivably invisible. With the wrong type of light, materials seem aged or discolored. This is why Premier has invested in a lighting division that specializes in LEDs, which reduce energy by up to 90% compared to that of typical halogen bulbs. Premier’s 3-X-1-watt MR-16s lights produce an equivalent 230 lm but at a higher color rendering index, providing an accurate representation of all materials and people. The positioning of the light can either wash the texture of the material away or enhance its natural beauty; it can increase purposeful reflections or create bright or unwanted hotspots.

One of Premier’s strengths is customization. When working on a project, the company deals with various elements. The initial phases of projects involve dealing with elevator companies, consultants and general contractors, which have building requirements. The work continues with the building owner, architectural firm and interior-design professionals from either the architectural firm or an outside interior-design company.

Rennick commented on the process:

“We have to satisfy these elements so the clients end up with the product they want, at a cost the elevator companies can afford to stay within their budget, and the timelines the general contractor requires to get the product installed. It is quite a juggling act, but it is one of our core competencies and a real strength to be able to take and understand the elements and bring them all together.”

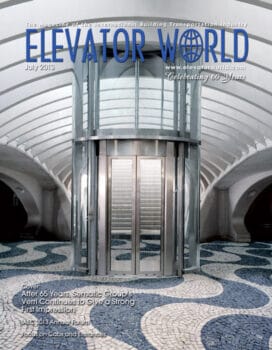

One of Premier’s recent projects was for Mississauga Transit (now MiWay in Canada). It involved a number of glass elevator cabs and entrances. It required significant coordination between Premier, Mississauga Transit, the elevator company, the architect and the general contractor. Glass has increased in prominence over the last five to eight years. Glass interiors offer a unique light effect, showcase the architecture, give passengers the illusion of an open space and provide a safety component. Along with the Mississauga Transit project, another key project that showcases glass elevator cabs is the BMW Toronto showroom. Here, Premier designed, built and coordinated the installation of the elevator cab, and worked with glaziers on the glass hoistways. “Glass projects are continuing to really escalate, in both the public and private sectors. We are now working on a number of glass cars in the residential sector, as well,” Rennick said.

Premier takes a hands-on approach to its work, which reduces the potential for problems. Bringing all project requirements together requires coordinating with the client from the beginning to understand what it wants to incorporate and whether this will meet building and elevator codes. “We have to gently guide them and shift them sometimes in different directions than they were initially looking at to ensure the product meets all the building and elevator code requirements,” Rennick said.

According to Dino Mele, Premier’s president and CEO:

“Our employees are definitely Premier’s greatest asset. They work very hard right from the start, [and] we have a live receptionist answering our telephones throughout the day, directing the calls, and getting the right people required hooked up quickly and efficiently.”

The company uses the latest technology in its scheduling and engineering programs, and in its design and rendering software, in combination with its onsite team, to complete the client “circle.”

Rennick said:

“Our dedicated sales team is often out in the field meeting with clients. Our engineering director, president and I are also directly involved in all the key projects on a day-to-day basis to ensure their fluidity and the satisfaction of the client. If that means meeting at 10 p.m. or having our installers there working through the night to not disrupt the building, we go the extra mile, and that philosophy stems right from when our phone is answered to when our truck driver delivers the product.”

Premier works to retain and build from its existing clients, and it prides itself on repeat business, while always looking for new companies with which to work. “We build on our referral base for our growth, as well as looking at the general dynamics of anticipated market growth,” Rennick said. Premier is an active member of the Canadian Elevator Contractors Association and the National Association of Elevator Contractors, and participates in the Canadian construction industry’s annual show.

Premier remains committed to the industry and its professionals. It plans to extend its project formula to other markets in the future. According to Mele:

“There is no reason we can’t take this formula to the larger U.S. cities with a greater intensity than we have in the past. Going forward, these are the areas to grow in. There are immense opportunities for us, and we have the product base and the knowledge to build from to be able to push forward.”

Get more of Elevator World. Sign up for our free e-newsletter.