Shaping Transformation Through Localization

May 23, 2023

Santosh Subbiah (SS), director, Sales & Marketing for Mother India Forming Pvt. Ltd., provides perspectives to your author (SSP) on the company’s evolution and significance for the vertical-transportation industry.

SSP: How has Mother India Forming Pvt. Ltd. evolved and grown over the past four decades? What have been the key developments or milestones achieved during this more than 43-year journey, including technological advances?

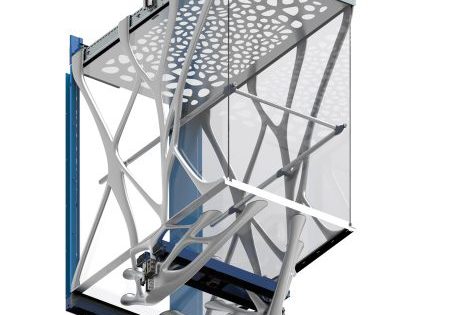

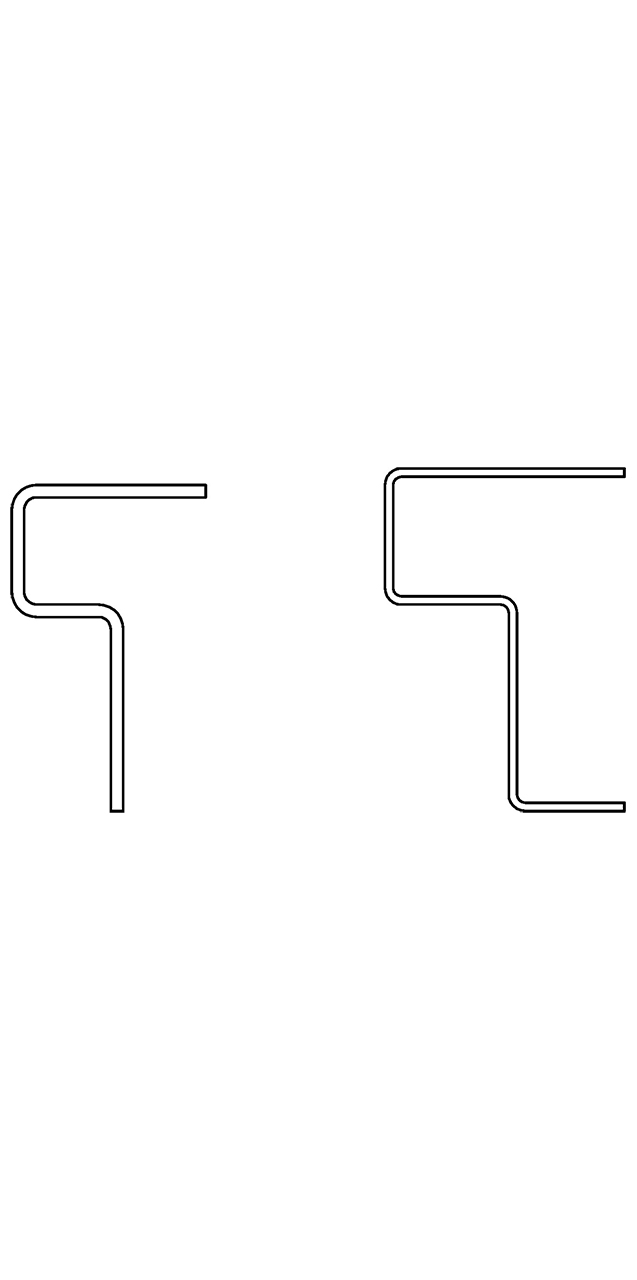

SS: Mother India is a leading organization with invention and innovation as its hallmark and has been making customized tubes and ready-to-use components for more than four decades now. Mother India has evolved as a one-stop solution for all tubular, roll-forming needs, and our operations are fully integrated. From developing a concept to components with computer-aided design, ideas are digitally conceptualized using the most advanced simulation software. Localization of imported safety critical parts in construction equipment, elevators, storage racks and the textile industry has made us front-runners in the roll-forming industry.

SSP Mother India operates at four different locations in Bangalore. What are the advantages of this locational focus for the company and its customers?

SS: Over the past 43-plus years, we expanded with more verticals being added into the business. This model gave us sustained growth with expansion being self-financed. While the company operates from four different locations right now, it is consolidating its operations to one single location near Attibele, Bengaluru, and will move there by July 2023. This will result in combining efficiencies, bringing together multiple jobs and simplifying operations for us.

SSP Mother India manufactures parts for a wide range of applications. What is the importance of construction equipment and elevators among them?

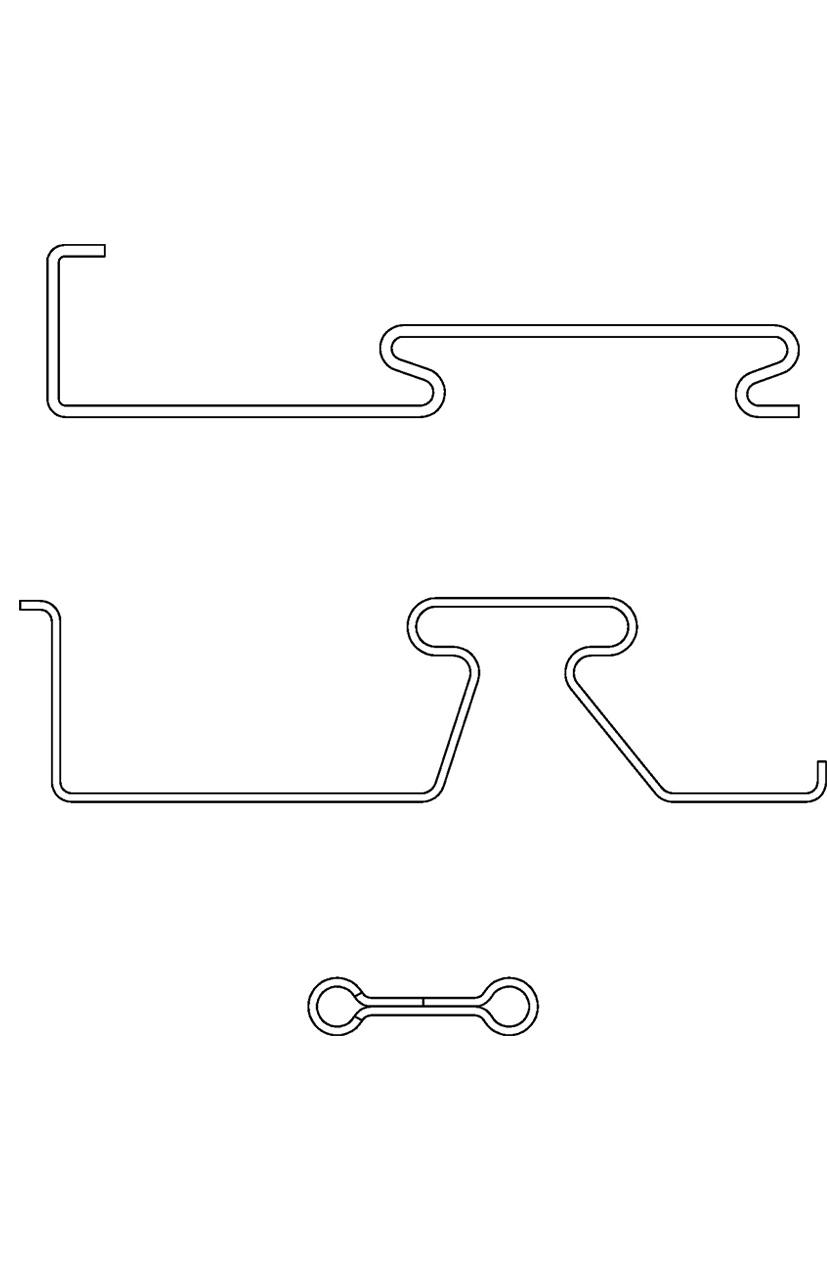

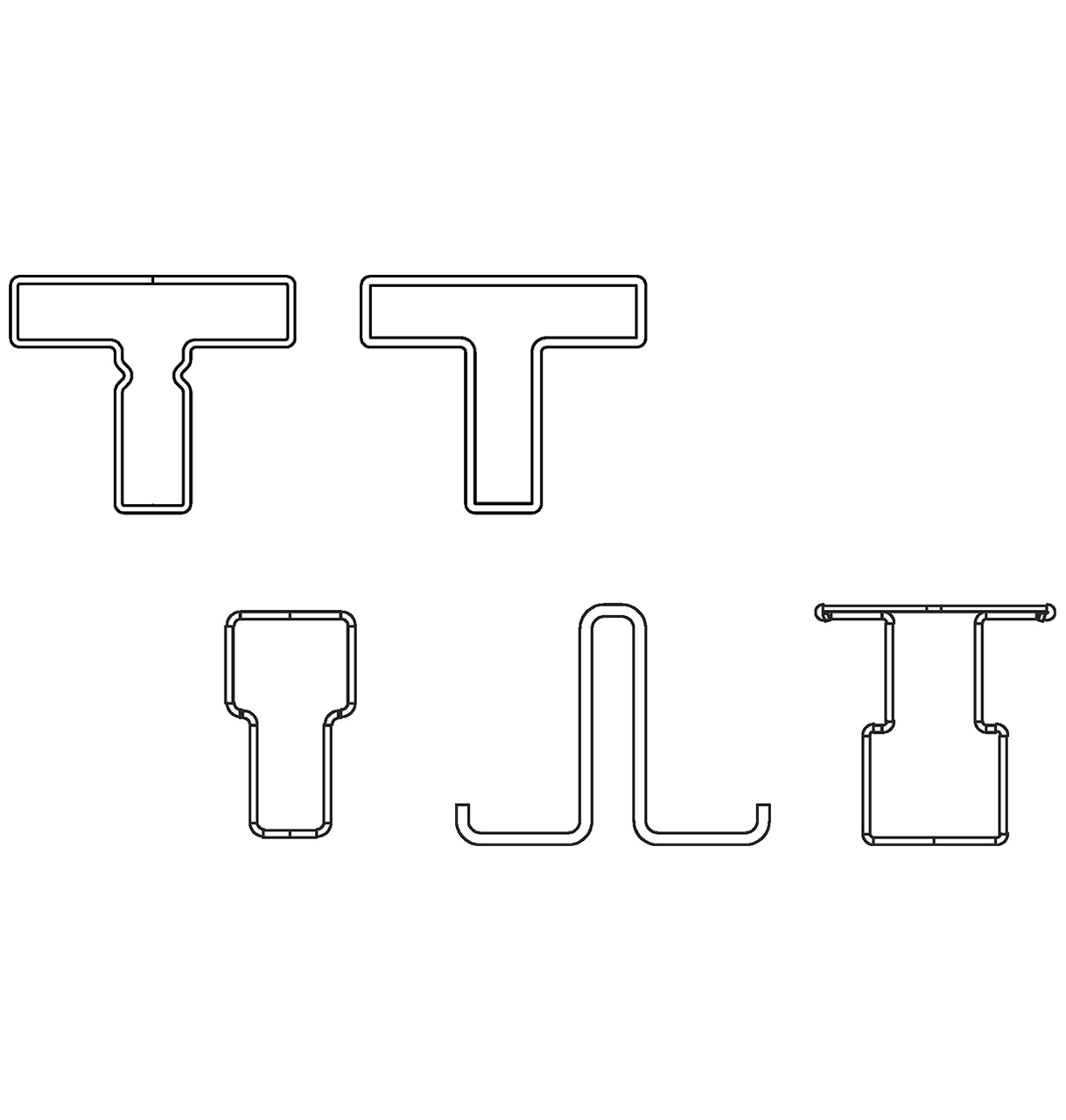

SS: Mother India manufactures parts for a wide range of applications, such as automotive, cabinets (electrical and network), construction equipment, elevators, formworks, furniture, storage racks and the textile industry. Among these applications, construction equipment and elevators are two important segments that require high-quality and safe, reliable parts. Construction equipment, elevators and FormWorks are essential for the development of infrastructure and urbanization in India. They enable faster and safer construction of buildings, bridges, roads and other projects. Mother India provides parts that meet the global specifications and standards of these sectors, such as driver cabin frames, door tracks, stiffeners, uprights and load-bearing members. By supplying parts to construction equipment and elevator manufacturers, Mother India contributes to the growth and progress of the country.

SSP What have been the demand patterns and requirements from the elevator segment for your products and services?

SS: The elevator segment has witnessed a steady growth in demand patterns and requirements in recent times due to various factors. Some of these factors include rapid urbanization, rising investment in commercial and residential infrastructure projects, increased focus on safety standards and growing preference for machine-room-less (MRL) traction elevators. According to various market reports, the elevator segment is expected to exhibit a healthy CAGR of around 6-7% during the forecast period of 2022-2029.

SSP As a source of global supplies to leading OEMs, what are the specified norms that you adhere to for the elevator segment?

SS: The elevator segment is a highly regulated and competitive industry that requires suppliers to meet various standards and norms. Some of them are:

- Quality management system: Suppliers must have a certified quality management system that complies with ISO 9001 or equivalent standards.

- Safety and performance: Suppliers must ensure that their products meet the safety and performance requirements of relevant codes and standards.

- Environmental and social responsibility: Suppliers must follow the principles of environmental and social responsibility like reducing waste and emissions, using renewable energy sources, respecting human rights and labor laws, etc.

- Innovation and technology: Suppliers must demonstrate their ability to innovate and adopt new technologies that enhance the efficiency, reliability and sustainability of their products and services.

Mother India has adopted and strictly adheres to these norms.

SSP Mother India has major elevator brands like KONE, Schindler, TK Elevator and Wittur in its portfolio, providing door guide rails and tracks, counterweight guide rails and stiffeners. What are the requirement types and frequencies from these brands that set this segment of your clientele apart from the others? What feedback have you received from them?

SS: Mother India is an ISO 9001:2015 and IATF 16949:2016 certified company providing components to the elevator industry that meet their global standards. The components produced by us are tested to meet those high safety standards. We actively contribute to the “Make in India” movement and have been aggressively supporting it.

A few major differentiators for our customers are:

- Safety standards per IS 14665: Part 1 National building code.

- Ride quality per standard ISO 18738, where the counterweight guide rail supplied by Mother India plays a major role.

- With rigorous cycle time testing and various safety qualification trials, our products have supported our customers to maintain these standards.

SSP What are your plans for Mother India and specifically for catering to the elevator segment?

SS: To date, with all the localization we have done in the elevator industry, there is about Rs 500+ crores worth of metal products that are still being imported. We are evaluating the business case to take necessary steps to localize such metal products, which will greatly benefit our customers in saving cost and time and in reducing carbon emissions.

About Mother India

Vision: Best practices and work ethics to support the transformation of nation

Mission: To continue leading the invention, innovation and challenging localized sheet metal component development and supply.

How we give shape to ideas: Profile Concept > Roll Forming Simulation > 3D Prototyping > Actual Profile > Bending Simulation > Final Product

About Santosh Subbiah

Santosh Subbiah is a mechanical engineering graduate of Bangalore University and director, Sales & Marketing, for Mother India Forming Pvt. Ltd. He started his career in Mechanical CAD/CAM/CAE. From early 2002, Subbiah developed markets in India for a high-end German software for sheet metal cold roll forming tools. In 2006, as the managing director of a German subsidiary in India, he expanded sales and services to the Arabic and South Asia Region. In 2014, Subbiah became associated with Mother India and localized several components for the construction equipment and elevator industries.

Get more of Elevator World. Sign up for our free e-newsletter.