Smart Hydraulics Guarantee Lowest Cost of Ownership

Sep 1, 2016

Making the case for hydraulic elevators with electronically controlled elevator valves

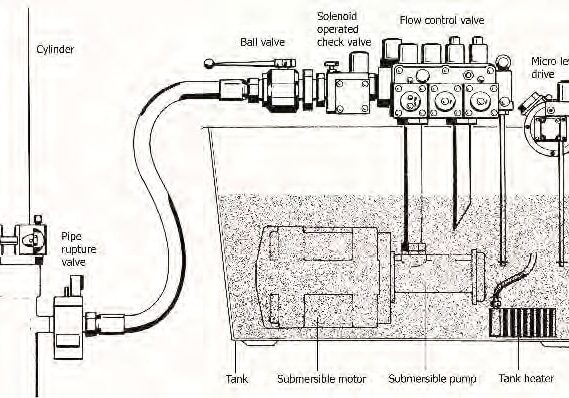

Bucher Hydraulics AG has developed and manufactured cost- and energy-efficient lift driving packages for decades. Its ability to offer a smooth ride, simple commissioning and fully automatic adaption to different load and temperature conditions is directly related to the electronically controlled lift valve.

Cost efficiency is becoming more and more important. Within the elevator industry, there is now a tendency to think beyond the initial investment. The end users recognize that the investment cost is only half the truth. A “cheap” installation could turn into a quite expensive one, considering also the operating and maintenance costs that occur during the entire lifecycle.

The typical proprietary systems provided by major elevator companies sometimes entrap building owners. Decisionmakers are now interested to compare not only the initial investment, but also relevant operating and maintenance costs. In addition, they would like to have the freedom to change the service partner whenever they want. This opens a competition that keeps prices for spare parts and services on a healthy level. Within this context, hydraulic elevator drives provide unique advantages, and this is valued in an increasing number of markets. Besides other advantages, this might be one further reason to keep hydraulic elevator drives in demand.

Of course, up-to-date cost efficiency may not be reached with old-fashioned hydraulics. To get the full benefit of their physical prerequisites, investments must be made in R&D.

High Technology Is the Key for Low Cost of Ownership

Forty years ago, Bucher’s elevator division (at that time under the company name Beringer), in Neuheim, Switzerland, introduced the first electronically controlled elevator valve, LRV. The product is still the benchmark for a highly reliable hydraulic control, providing high riding comfort at a low cost of ownership. The quality foundation of this electronically controlled lift valve led to several developments within the hydraulic-drive market. Further advantages that contribute to reduced costs of ownership are:

- Short installation time

- No wear and tear on moving counterweights

- Hydraulics are simple and easily accessible – this results in fast and cost-effective repairs

- Inexpensive spare parts

- Drastically reduced maintenance costs compared to traction elevators, since no sheaves and ropes need to get replaced

- Increased shaft utilization due to no counterweights

- No expensive headroom designs required

The main goal of the LRV’s design is unsurpassed riding comfort independent of load and temperature. In addition, the efficiency of the drive is already remarkably higher than that of conventional mechanical valve blocks. Depending on the application, using the electronically controlled valve results in up to 30% less energy consumption compared to mechanical designs. This results, of course, in 30% less heat, which is favorable for all groups involved. As a final benefit, many applications do not require an oil cooler, as they do when running with conventional mechanical valve blocks.

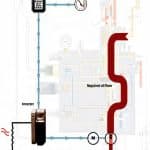

Other features include a touchless feedback device showing the current oil flow rate. Due to the touchless “Hall-principle,” it works maintenance free throughout the product’s lifespan. Additionally, a proportional valve controls the bypass oil flow, resulting in the correct flow rate provided to the cylinder.

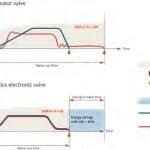

Note in Figure 2 that the motor runtime is shown on the X axis. This means the covered distance for one ride is the same, but, obviously, the runtime may vary drastically when using a mechanical valve. This results in a huge energy-saving advantage for the electronically controlled valve. A further money-saving fact is less downtime due to changing running conditions (e.g., changing ambient temperature or payload). This prevents unscheduled service interventions, which would be necessary on mechanical valves to adapt the mechanical adjustments to new conditions.

Figure 2 clearly shows the energy-saving potential of up to 30%, by just being accurate and “on time” at the top floor. This is ensured by the fact the ride curve is maintained, no matter whether the elevator is run with a full or empty cabin, or hot or cold oil. Hence, you just run the installation with the preset parameters, and the installer may set the timing for the deceleration signals at its preferred timing sequences. This ensures there will always be:

- No deviation due to changing operating conditions

- The same starting point

- The same creep speed distance

- The same acceleration/deceleration slope

- The same speed

- A smooth ride without turbulence

Furthermore, no oil cooler results in several advantages:

- No cutout for the hosing/piping to the cooler

- No expensive air-conditioning

- No noise emission or extra energy consumption of cooler fans

Inverter Technology Increases Hydraulics’ Efficiency

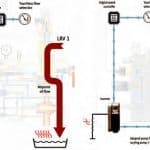

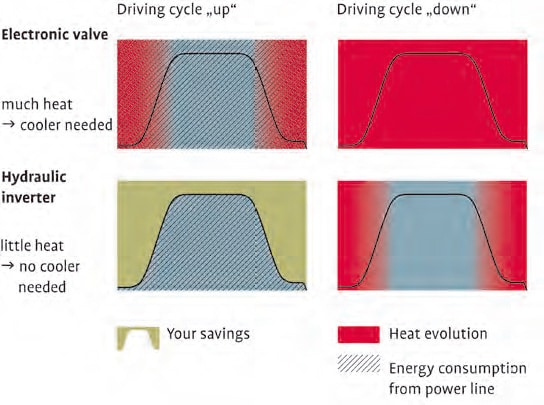

By using a frequency inverter to control the speed of the hydraulic pump, the efficiency of the hydraulic drive increases remarkably. As a result, the thermal loss gets further reduced, compared to the good values of the electronically controlled valve. The oil flow gets mainly controlled in both directions by the pump speed, which is determined by the individual speed of the attached motor.

The right sketch in Figure 3 shows that the heat loss can be dramatically reduced by using inverter techniques. This brings another important advantage: the small amount of remaining heat dissipation can be forwarded by a small cable from the inverter to a brake resistor, which is far less expensive than hosing/piping with required cutouts in the building structure to connect a conventional oil cooler. Additionally, there are fewer noise emissions, and no delays or current peaks when the motor starts.

Conclusion

Although energy costs considerations are major, choosing a system with low maintenance costs is even more important. In fact, maintenance costs can typically far outweigh power costs. In case of higher traffic demand, up-to-date hydraulic-drive technologies, such as Bucher’s inverter solutions, meet this request. It provides high energy efficiency without the need to sacrifice the enormous savings in maintenance costs of hydraulics.

The following list gives some final arguments why hydraulic lifts are cost effective:

- Lowest initial investment costs up to five floors

- Simple commissioning

- Lower wear and tear than traction applications

- Twenty percent fewer parts involved for less maintenance

- Easy and fast access when maintenance is required

- Electronically controlled hydraulic valves ensure high reliability and guarantee minimum required service.

- Service partnerships can be procured on the free market.

- Figure 1: A simplified overview of the working principle of Bucher’s electronically controlled lift valve LRV during an upward ride

- Figure 2: A comparison of the high accuracy and ride performance of the electronically controlled valve technology compared to that of a mechanical valve

- Figure 3: Comparison of an electronic valve and a hydraulic inverter in a downward ride

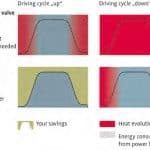

- Figure 4: Comparison of an electronic valve and a hydraulic inverter’s heat and energy consumption

Get more of Elevator World. Sign up for our free e-newsletter.