Taipa Houses-Museum Pedestrian System Macao, China

Jan 1, 2018

Quality of life is improved for residents of important cultural/historical complex.

submitted by Jiang Liming, Suzhou Rhine Lift Manufacture Co., Ltd.

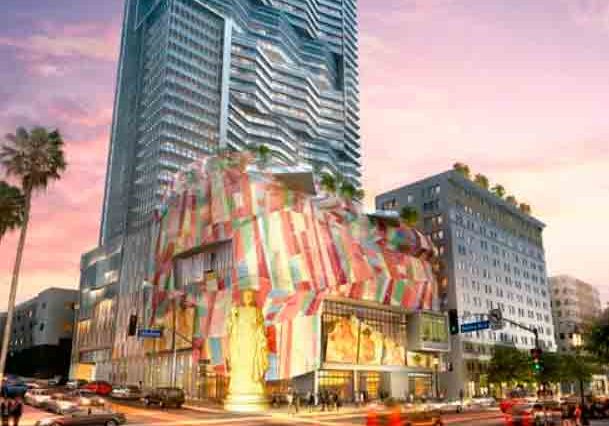

The Taipa Houses‐Museum is a tourist attraction on Taipa island of Macao. The museum complex consists of five houses, which were originally the residences of senior Macao officials during the Portuguese colonial era. They were built in 1921 and transformed into the Houses‐Museum complex in 1992. The government created a multicultural leisure area and built a platform for showcasing the culture of Portuguese‐speaking countries and international cultural exchange, which was opened to the public in 1999. To enhance the important historical and cultural Macao architecture, the surrounding environment of the Taipa Houses‐Museum was optimized in the interest of preserving the original characteristics of the buildings.

The Taipa Houses‐Museum Multicultural Leisure Area is one of the Eight Attractions of Macao. It includes the Houses‐Museum, Notre Dame Scarlett Church, Taipa Library, Taipa Municipal Garden and Cross Garden. There is a mangrove wetland in front of the museum, where people can see black‐faced spoonbills, egrets, grey herons, kingfishers, mandarin ducks and more.

The Macao government began plans to build a better leisure and exercise facility in September 2014 to improve the life quality of nearby residents. The “Taipa Pedestrian System from Lakeside Garden to Houses‐Museum” starts from the Lakeside Mansion overcrossing and goes along the Father Situ Zexiong Road to Mount Tai Tam Observatory, from which people can take an inclined elevator to Ka Lok Bailey Road. People can go from the Ka Lok Bailey Road to the Recovery Street and then the Houses Museum, Taipa Old District and the St. Lazarus’ Bay Road.

The transportation of people along the slope from Mount Tai Tam Observatory to Ka Lok Bailey Road is one of the biggest problems. The Macao government turned to Suzhou Rhine Lift Manufacture Co., Ltd. to solve this problem with an inclined elevator. On receiving the request, Rhine’s team went to the site to investigate its condition. We then made a satisfying slope transportation plan. With the joint effort of our technology, production, quality control, engineering and other departments, we finished the project, which passed inspection on October 6, 2016.

Installation

As the construction site was in a very small and heavily trafficked area and the elevator parts (especially the H‐shaped guide rails) consisted of heavy, bulky material, logistics and assembly were major challenges. We also needed to make sure the process didn’t affect the traffic on the road.

Two windlasses were placed separately at the top and end of the slope to set the H‐shaped guide rails in position and assemble them. Compared with the traditional method, this greatly shortened the time needed for installation and obviously improved work efficiency. And, of course, this also reduced the effects on the traffic of the main road to the largest degree.

Technology and Design

The elevator uses a rope gripper as the executive component of unintended car movement protection (UCMP), which is safer than braking via traction machine. According to the GB 7588‐2003 Safety Specification for Elevator Manufacture and Installation’s national “No.1 Modification List,” 9.11.1, the protection for unexpected movement of the car doesn’t include the failure of hanging rope, chain, traction pulley, roller and chain wheel. Also, the failure of the traction pulley includes the sudden loss of traction force. So, there is still risk for passengers to pass through the car door when the traction force suddenly disappears. Using the rope gripper, the sensor will detect car movement in the case of traction-force loss and then trigger the device to grip the steel rope, which can make the car stop reliably and ensures the safety of passengers going through the car door.

The rails’ surfaces and joints are milled, which makes them smoother so the running of the elevator can be more fluent. At the same time, the milled rails save energy to a great degree.

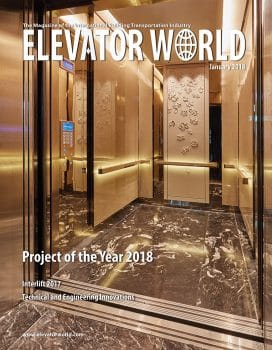

The design of the car adopts a simple and modern style. The car is made of 304 hairline stainless steel. The surface is coated by fluorine and carbon as an anticorrosion treatment, which gives a glazed texture. The four round corners make the car look soft and relaxing. The round corners are produced through constant bending, which reduced the production cost to a large degree and represents technological progress. To ensure the precise connection of the car parts and to satisfy the design, the car needed to be adjusted constantly in accordance with the jobsite conditions during assembly. Eventually, we realized it perfectly.

Bottom Support Structure

A backpack frame structure is used more than a bottom support structure for inclined elevators with angles greater than 45°. But, the latter has a simpler structure, and the passengers can have a 360° view. To realize the bottom support structure, the barycenter was designed to be near the rear of the car; otherwise, the car would easily lean forward, which would hinder the running of the whole elevator. We reinforced the bottom to move the barycenter backward to let the elevator run steadier.

By using inclined elevators (instead of traditional vertical elevators and escalators) to solve the transportation issues along the slope, the Taipa Pedestrian System from Lakeside Garden to Houses‐Museum is a breakthrough in public-transportation systems.

Get more of Elevator World. Sign up for our free e-newsletter.