Technology Redefining the Future of Elevator Installation Methods for High-Rise Buildings

Sep 1, 2024

A look at how the methods have progressed from the traditional to breakthrough construction technologies

by Philip Hofer, Urs Püntener and Miguel Castro

This paper was first presented at the 14th Lift & Escalator Technologies Symposium in September 2023 and published at Lift Escalator Library

Keywords: Installation, Scaffold & Scaffold-less, Climb lift, False Car, BIM, Robots

Abstract

The installation of lift guiding systems is fundamental to the ride quality felt in the car. This paper will look at typical elevator installation methods and the technological journey of elevator installation in the construction business. Traditionally, elevators were installed by fitters using scaffolds to access the hoistway, aligning the guide rails and adjusting the distance between them. The process was often quite challenging for the installation teams, as safety was the main concern along with the physical strain of working in a harsh environment. The process then progressed further to scaffold-less installation methods with temporary suspended platforms, which offered improved safety standards according to the guidelines defined in EN 1808 and GB T 19155. At the same time, climb elevators were developed as the building industry required elevators to be installed and operational while buildings were progressing in the construction phase. Today, new technology has allowed robots to become mobile, leaving the factories for robotic installation systems for lifts on construction sites. The repetitive tasks and harsh environments that challenged humans can now be done with the high quality and precision of robots.

1. Introduction

The correct installation and alignment of guide rails to form the lift’s guiding path are fundamental in achieving acceptable levels of ride quality in the lift system. Installation methods are continuously developing to fulfill today’s challenging market requirements. Safety, manpower, labor shortages and installation time optimization are key drivers for developing new installation methodologies of the future.

This paper will take a brief look at how installation methods have progressed from traditional scaffolding to breakthrough construction technologies for lift installations of today and the future.

The vertical-transportation (VT) industry is a very special discipline within a building. While most disciplines base their design and models on a floor-by-floor basis, VT manufacture must inevitably cross more than one floor at a time.

As lift installation projects are complicated and time-consuming, proper on-site management and defined processes are mandatory for a successful project. This also includes better site coordination and on-site material logistics, as material storage is generally challenging on large projects.

2. Lift Installation Methods

2.1 Scaffold

Traditionally, a scaffold was supplied by the main contractor in order to install the shaft material, and generally, scaffolds were a concern for the health and safety of the installation personnel. Additional work was required to bring scaffolds up to the standard expected to ensure that employees could carry out installation tasks. Scaffolding was often in the way of components being installed, like landing doors, and required continuous alteration to suit the lift system being installed, and often, safety procedures were compromised with people working above each other.

The scaffolds generally had quite a low installation efficiency, as materials had to be transported to the individual floors and then hoisted into the shaft. Such methods also had no defined method statements or risk assessments to define the installation sequence with the appropriate tooling supplied. It was generally up to the subcontractor to decide how they would install the unit based on previous experience without training.

Although fitters were wearing a fall protection safety harness connected to a rope in the shaft, the general working environment was quite dangerous and physically demanding with the constant danger of debris falling down the shaft.

Furthermore, rental costs for scaffolds over longer periods were expensive for shaft heights of up to 500 m. Also, the structural loading on scaffolds is quite questionable, with excessive heights required for high-rise lift installations.

2.2 Scaffold-less Installation Methodology

As safety standards were raised across the whole lift industry, building contractors were also pushing for safer installation methods with a clearly defined process. One major building contractor was pleased to have an installation method that mitigated risks based on sequential method statements for the entire installation process. This allows for a safe and independent installation methodology to be deployed over all product lines. The method also has a high degree of independence regarding the builder’s readiness, allowing for greater flexibility to commence the installation work on the job site, as soon as the shafts can be handed over.

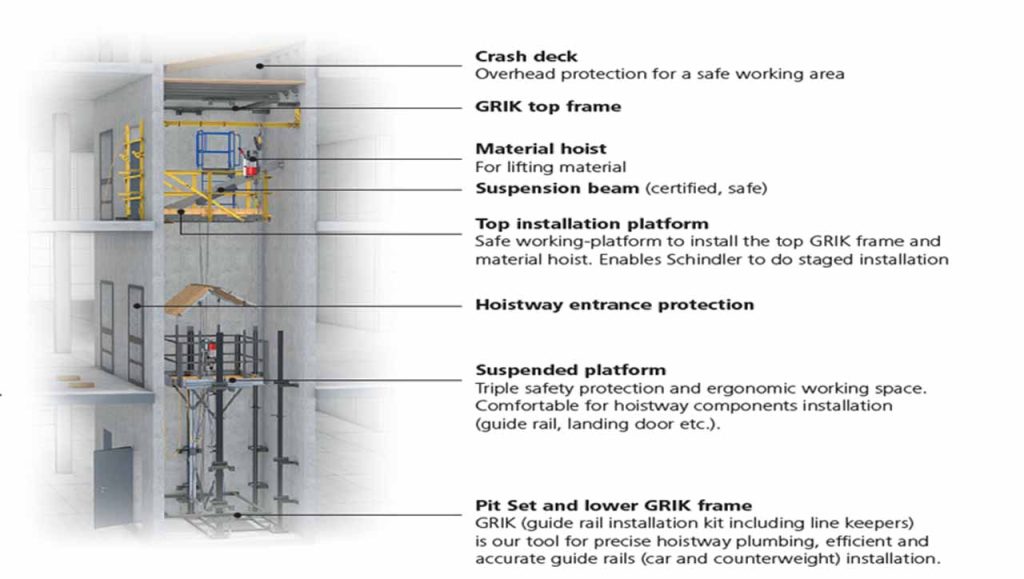

Scaffold-less installation methods (SLIM) were developed and certified to create safe working environments for the installation teams, with the highest safety standards according to EN1808:2015 Safety requirements for suspended access equipment – Design calculations, stability criteria, construction – Examination and tests.[1]

The SLIM is adjustable for all shaft dimensions and travel heights. Thanks to the pre-engineered material, it can be reused numerous times. The suspended platform, or false car[2] as it’s called, has three independent safety redundancies: primary rope with hoist, secondary rope with fall arrest device and independent free fall safety gear acting on the guide rails. The safety gear is automatically activated with spring force the instant that no suspension members are detected.

One of the main advantages of the methodology is that installation can start while the building is still under construction with only temporary power supplies available. The so-called “staged installation process” is applied, where the installation teams can work under the safety of a crash deck, temporarily installed in the shaft. With a staged installation, a shaft platform is installed along with suspension beams for the hoisting ropes to suspend the false car. The whole installation kit rises with the construction of the building. Once the final building height has been reached and the machine rooms handed over, the lifts can be finished.

The SLIM offers flexible, safe and tailor-made solutions to meet project specifications, allowing the customer to have the lifts ready for handover at an earlier stage or to be further utilized as builders’ lifts throughout the construction phase.

SLIMs still require a guide rail installation kit (GRIK) to be installed as a reference to plumb the shaft for the accurate positioning of the rail brackets and guide rails. The GRIK enables the guide rails to be positioned within a tolerance of 0.5 mm to be able to achieve superior ride quality at 10 m/s2.

Generally, the advantages for the installation fitters are:

- Clean, safe and bright working environment

- Being able to move the false car into position at the optimal height for drilling

- Stable platform working area instead of open scaffolds

- Optimal room for hoisting and positioning rails in the shaft

Customers are often confronted with different on-site situations; solutions need to be optimized and tailored depending on the construction site requirements and progress.

A. SLIM, topped-out installation.

The machine room with a concrete slab and machine beams already exists for the suspension of the false car.

B. SLIM, staged installation.

The complete shaft platform is installed with a Lean2Beam for suspension points and the templates for the plumbing of the shaft.

This option allows for fast execution since it can be continuously moved in line with the construction of the building.

2.3 Digital Quality Assurance

During the installation process, it is important to do quality checks (QC) at each hold point to ensure the equipment is installed at the expected precision. Once the car is installed and the lift system is operational, it is too difficult to make the necessary adjustments and rail realignment.

- QC1: Guide rail alignment

- QC2: Landing door alignment

- QC3: System Check

These checks are done fully automatically with the QC-APP, which allows the quality inspector to execute the three checks in a paperless way, using his/her mobile phone — measurements, photos and reports will be uploaded to a cloud where they can be analyzed via a power BI (Business Intelligence) solution, transparent to all stakeholders.

2.4 Climb Lifts

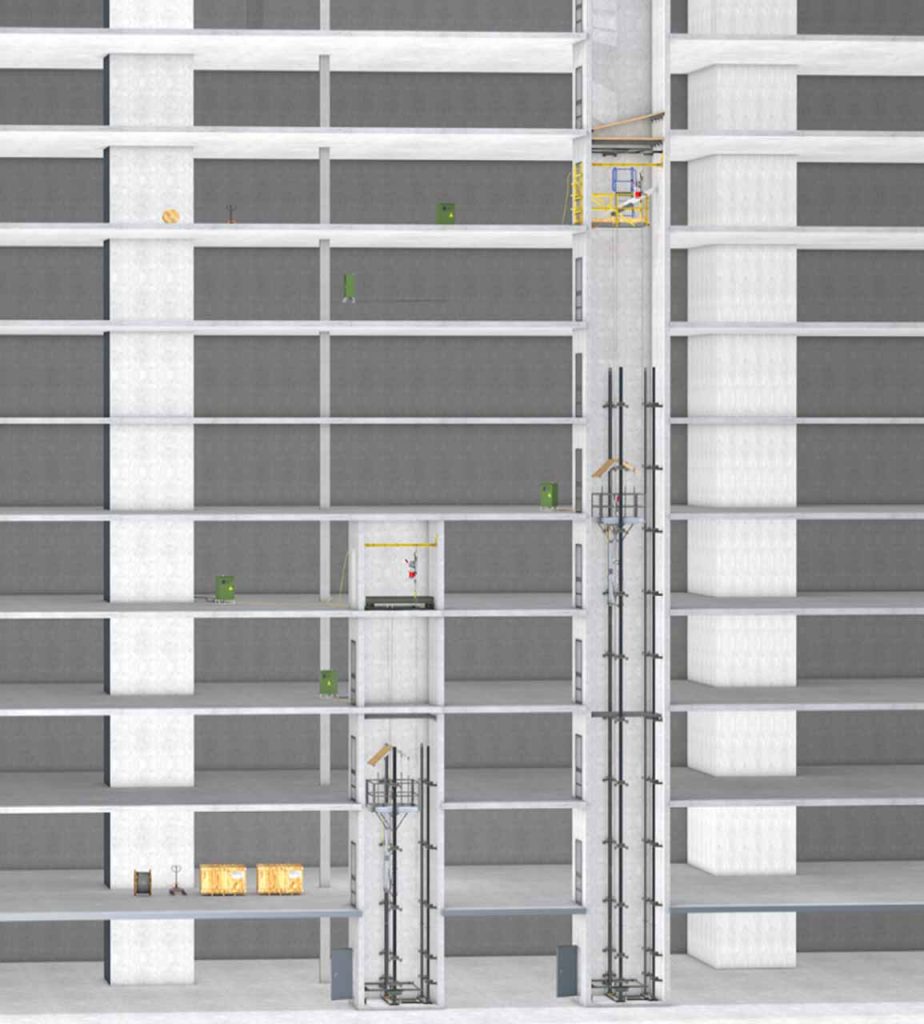

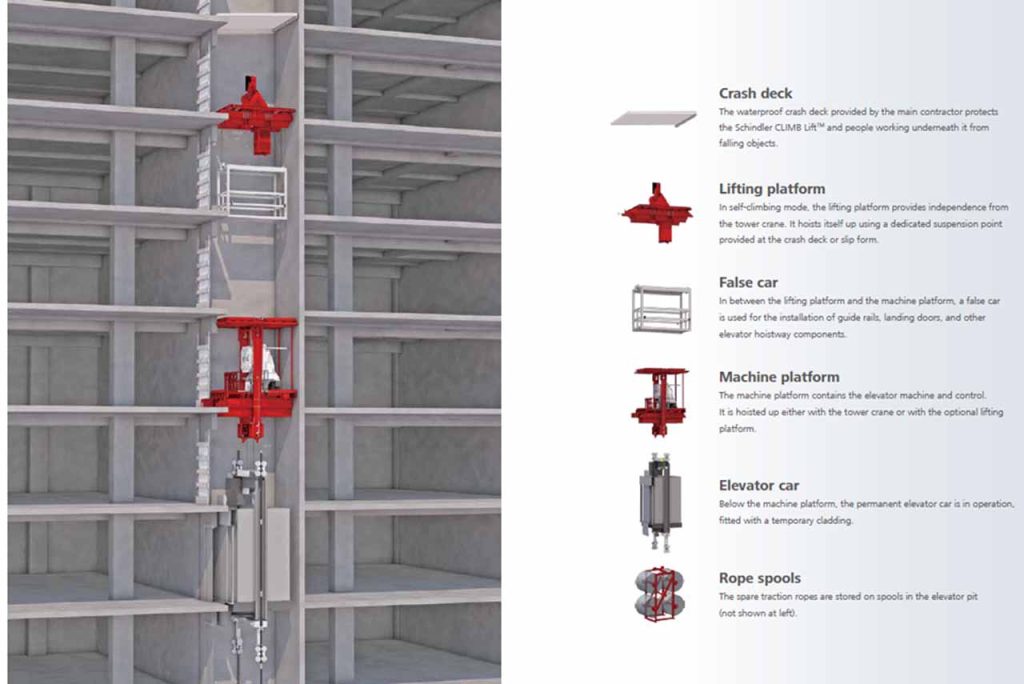

Climb lifts are basically fully operational lift systems that utilize the permanent shaft, generally located central to the core of the building. They have a temporary machine room that moves upwards (“Climbs”) in the shaft as the construction of the building progresses.

The main advantages of a climb lift are:

- A faster construction process, enabled by lifts being able to travel at higher speeds compared to the conventional rack-and-pinion Alimak lifts on the outside of the building.

- They are self-climbing using dedicated suspension points at the crash deck or slip from and therefore can be independent from the building site crane if required.

- Increased safety, security and comfort, especially during severe weather conditions, when generally an Alimak would be out of service. Also, the added advantage of 24-h operation with no noise disturbance is due to the central location.

- Much earlier availability of permanent lifts in the building and the fact that the façade of the building can be progressively closed to allow the customer to rent out the building on lower floors while the construction above continues.

- The methodology requires pockets at the rear wall of the lift shaft to allow the retractable support beams of the machine platform to be inserted and the front beams to remain securely on the floor slab.

The general installation method of climb lifts follows the same methodology as SLIM with a false car as a suspended platform. The installation fitters can work safely from the platform of the false car, moving up and down to install the guide rails in the section above the climb lift.

2.5 Benefits of Using Building Information Modeling During Installation

Building Information Modeling (BIM)[3] is defined as a collaborative way of working using digital technologies that allows all parties in a construction project to work more efficiently throughout the project life cycle (from concept design to operation). Previously, pre-created families of products were supplied to clients; now, this can be done by fully coordinated BIM models with individual components that form the elevator or escalator system and contain all the relevant information used throughout the life cycle of the asset. Each of the elevators and escalators provided are tailor-made for each individual project. The uniqueness of this approach guarantees a higher level of integration and collaboration within the projects and creates personal relationships and trust in the quality of the work performed, which is positively valued by the customers, especially in large and complex jobs.

The installation of climb lifts is not only a technical challenge, but also a fine-tuning exercise where all parties must work in unison. To assist in this process, BIM offers the possibility to time-phase the models to coordinate material installation, transportation of material within the construction site, crane operations, temporary works and more importantly, the jumps.

The use of BIM allows you to leverage the data available in traditional project management tools such as Gantt Charts (data source) and link it to specific components in the BIM models. By linking this data, the site team will get a visual overview of the project, and tasks can be assigned to components, groups of components, etc. (Granularity will depend on each specific scenario and the tasks to be performed). Once the model setup is finished, the site team will amend the data source when necessary and the simulation will be automatically updated to reflect the current installation status.

3. Robotic Installation Methods

As we are entering the new era of digitalization in the building industry, the question arises of how technology can support us in shaping the future of smart high-rise buildings. One answer was to look at what applications exist for robots in the construction industry and, more specifically, at lift installations that require repetitive and physically demanding tasks with a high level of accuracy.

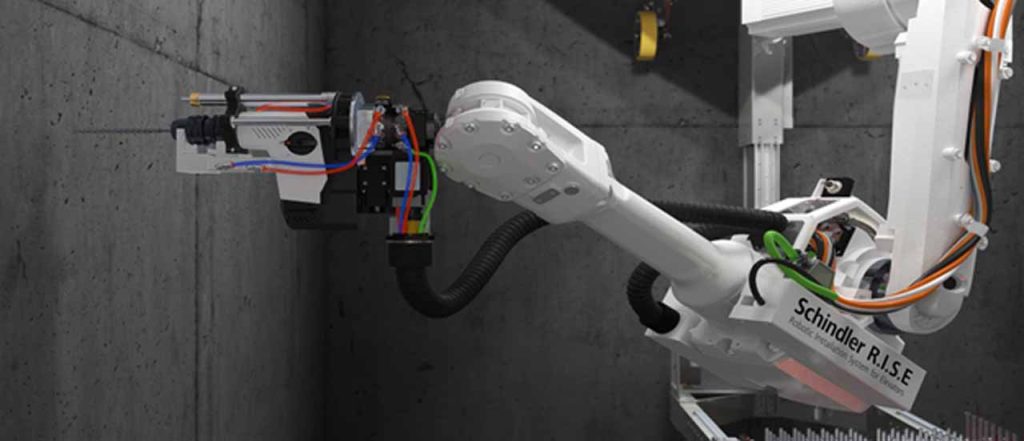

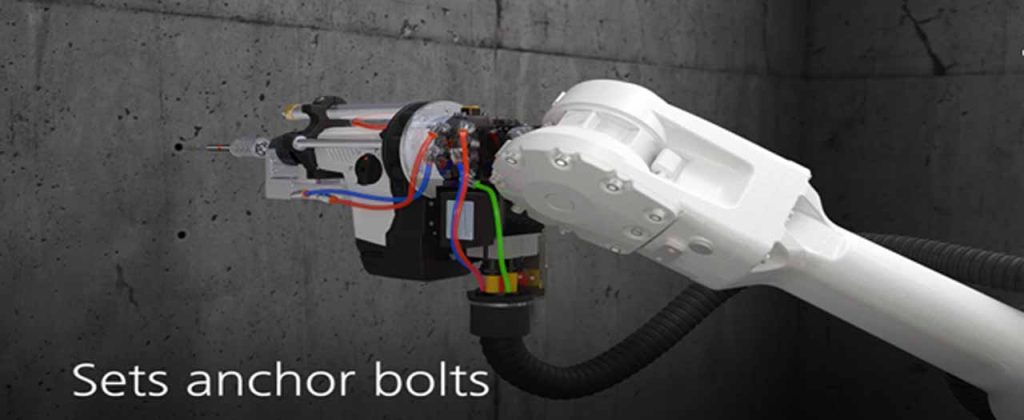

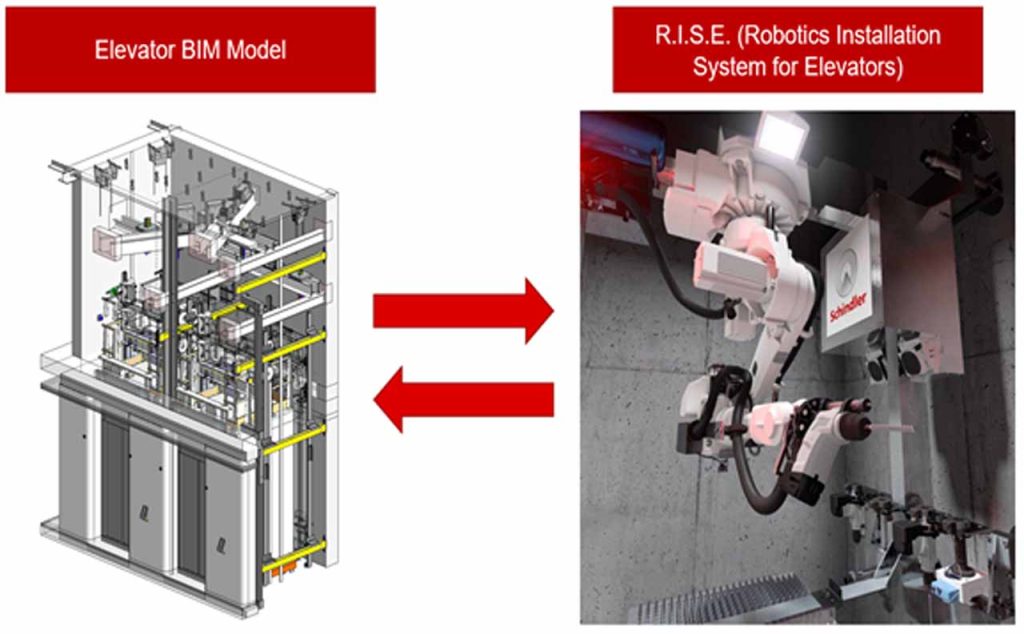

Robotic installation system for elevators (R.I.S.E) combines AI with lift technology to make lift installations safer and more efficient with automated accuracy.

Schindler R.I.S.E consists of an industrial robot that is mounted to a movable platform: The power supply requirements are 400 V/50 Hz, 30 A, three phase + neutral + earth. The platform is winched up the shaft to the next defined drilling position where the platform bracing system is released, locking it into position. The robot obtains the positioning data automatically from the BIM models to identify the position for drilling the holes.

The robotic arm then selects the rebar scanner to scan the shaft wall, identifying the position of the rebar under the concrete. With the information on the location of the rebar, the hole position for the rail brackets can be compared with the uploaded digital data and adjusted accordingly to avoid drilling in the rebar.

Then the robotic arm returns to the tooling station where the impact drill is selected to drill all holes at the pre-determined position. Once the holes are drilled, the anchor bolts are set and pre-tightened ready for the bracket installation.

With all the holes drilled and anchor bolts set, the installation team can quickly install the rail and brackets from an installation platform like the lift car or false car.

The Schindler R.I.S.E fleet has already been successfully deployed on four continents, delighting customers, main builders,[4] supervisors and fitters on dozens of Schindler’s large projects.

The benefits of Schindler R.I.S.E are:

- Health and safety of personnel are not compromised by being subjected to work in the shaft.

- Significant time reduction in the measuring, drilling process and anchor bolt setting.

- High precision and quality of repetitive tasks.

- Automatic documentation with installation protocol.

- Attractive job profile for the Schindler R.I.S.E operator.

3.1 Schindler R.I.S.E – Bidirectional Dommunication

Intelligent BIM models can transfer the coordinates of the anchor bolts to Schindler R.I.S.E. This process is meant to be seamless and bi-directional, or in other words, the robot will pick up the coordinates from the BIM models, and once the anchor bolt installation has concluded, Schindler R.I.S.E will send the information of the coordinates back to the BIM models to obtain a level of accuracy of the as-built information never seen before.

The accuracy of the information provided by the robot is made possible thanks to the state-of-the-art technology the robot incorporates. In addition to the anchor bolt setting, the robot also incorporates a laser that measures the shaft dimensions at each bracket height, as well as a rebar scanner that can detect the position reinforcement bars embedded in the concrete and reposition the anchor bolts accordingly in case of a clash. This information can be sent back to the BIM models once the anchor bolt setting has finished.

4. Conclusion

The VT industry has come a long way from traditional scaffold installations with risk assessment-based installation processes. Lift shafts are harsh environments with humid and damp conditions, where the safety of employees is the main priority with any installation method. For lift systems to operate optimally, they must be installed with a high level of accuracy for the buildings that they were designed for.

The use of digital engineering, new technologies and AI is changing the lift installation process. According to Oetterli,[5] the vast range of new technologies and opportunities may also lead to a re-thinking across the construction industry about incorporating technology providers earlier into the design process for buildings, to deliver best-in-class holistic solutions for customers.

Digital innovation and state-of-the-art technologies have enhanced processes across the industry, not only in the way that internal processes and projects are delivered but also in the way that architects, developers, builders and consultants receive information throughout the project cycle.

The future of lift installation will also see an increase in prefabricated and modular construction where pre-assembled components can be assembled into a complete lift system.

New and future engineering development will not only benefit customers, but the innovative technologies will also help to motivate and develop employees.

References

[1] EN 1808:2015, Safety requirements for suspended access equipment – Design calculations, stability criteria, construction – Examination and tests.

[2] Wurtec False Car Installation Guide.

[3] “Lift Industry and BIM: a long overdue adopted and typically overlooked project enabler.” Miguel Castro, 13th Symposium on lift & escalator technologies, Volume 13

[4] “Uptown tower in Dubai becomes the world’s first supertall tower to adopt robotics for lift installation” — BESIX

[5] CTBUH Journal 2019, “Ask a CTBUH expert: Thomas Oetterli.”

Get more of Elevator World. Sign up for our free e-newsletter.