The Next KEB Generation

May 1, 2022

Company’s North American F6 elevator VFD addition to offer more abilities.

For nearly 20 years, the KEB F5 VFD (variable-frequency drive) has been used in the industrial automation and elevator markets. Its vertical-transportation (VT) product, the F5 VFD, has been used in elevator applications ranging from small, in-home elevators to high-speed lifts in tall skyscrapers. Various hardware, software and user interface upgrades have adapted the F5 over its lifespan to make it suitable for some of the toughest high-profile elevator applications. High peak current overload capability, advanced motor control algorithms for permanent magnet synchronous motors and dedicated elevator application adjustment parameters have made it a solid choice for the industry. However, as the F5 product matures and approaches the end of its lifecycle, KEB has been working to develop the next generation: the F6 VFD.

The F6 VFD is KEB’s sixth-generation VFD. Like the F5, it will be used in both industrial automation and elevator applications. The F6 has been in development for several years, and prototypes are currently being tested in the company’s North American manufacturing facility. The F6 will eventually replace the F5 product line in power ranges of 3 hp to 300 hp, in 230/460-V classes. Using the latest insulated-gate bipolar transistor (IGBT) and microprocessor technology, a completely redesigned power stage allows the F6 to occupy a much smaller physical footprint, compared to the F5.

The F6 power stage will feature an output current overload profile consisting of three parts: long-term, short-term and emergency. The short-term current overload rating of 5 seconds provides between 220%-300% of output-rated current to the motor, depending on unit size. The emergency overload profile is intended to be used in conjunction with the emergency terminal slowdown (ETS) function and allows a high-peak current overload rating between 240%-325% of output-rated current (for 1 second), depending on unit size. This feature reduces the need to upsize drives to perform ETS tests.

F6 User Interface

The F6 user interface, sometimes called operator or keypad, will have a parameter structure based on the current F5 LCD operator. Parameter names and layout will be identical, meaning elevator adjustors will not have to learn a different parameter structure. Advanced diagnostic screens and parameter upload and download capability will remain. Additionally, the KEB Elevator app will be able to interface with F6, allowing smartphone access to diagnose, troubleshoot and adjust parameters.

Multi-Encoder Technology

The F6 contains multi-encoder technology that features one programmable encoder feedback interface that can be set to work with multiple encoder feedback types. Interfaces, such as incremental TTL, EnDat and SinCos encoders, are all supported. Additional encoder feedback options, such as EnDat 2.2 and BiSS, are being tested for use in the elevator application.

The F6 features an advanced synchronous motor control algorithm that allows permanent magnet motors to be run in open loop (without encoder feedback). This capability can help troubleshoot encoder feedback problems, such as faulty hardware or ride quality, which previously were not available for permanent-magnet motor applications.

Brake Control

The F6 contains a dedicated brake control board that can be used to operate the release of the motor brake. The module contains a dual solid-state output with short circuit and failure detection. It is capable of directly supplying 24 VDC brakes up to 2 amps, or it can supply high voltage brake contactors with 24 VDC coils. The board contains two 24 VDC digital inputs that can be connected to a monitoring contact on the brake or separate contact to provide the drive with brake-release feedback.

This board also contains terminals that can be used for motor temperature measurement. PTC-, KTY- and NC-type temperature sensors are all supported.

Safety Module – Functional Safety

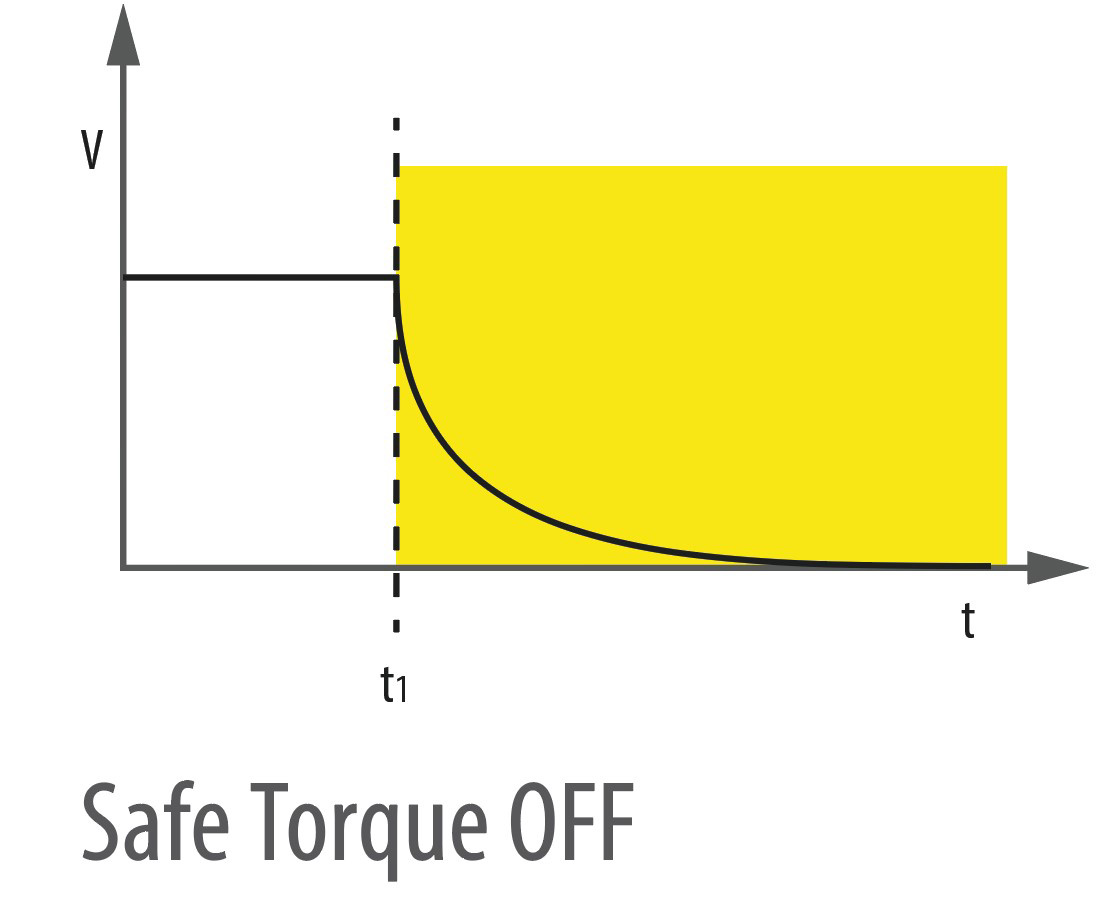

Functional safety as defined by IEC 61800-5-2 is an international set of standards meant to define “safe” states of a machine or area of machines involved in industrial automation applications. The standard defines these functions and, ultimately, it is up to the machine builder OEM to implement these functions. One of these functions, Safe Torque OFF (STO), will be standard on all F6 VFDs. STO is defined by IEC as “no torque at the motor shaft” (Stop category 0 in EN 60204-1). STO is a safety-rated circuit that must provide two unique methods of torque off to the motor, preventing rotation. Changes to both ASME A17 and EN 81-1 lift standards make it possible to utilize STO-rated VFDs and eliminate motor power contactors. When correctly applied, drives with STO can meet both ASME A17.1-2010 and EN 81-1:1998+A3:2009 standards.

F5 to F6 Retrofits

KEB has been supplying F5 VFDs to the elevator market for nearly 20 years. It is crucial to the market to provide a product that can easily replace the F5 once existing field installations reach the end of their designed life. The F6’s smaller physical footprint means that it will fit in existing controller panels. To make the transition easier, F5 to F6 mounting brackets will be available, meaning no additional holes will need to be drilled. Encoder and control terminal strip adapters are also in development, further easing the transition.

Summary

The F5 drive has proven itself as an incredibly innovative and versatile product in the most demanding, high-profile elevator applications. While the F5 will continue to serve the market for several years to come, eventually it will be replaced by the F6. KEB promotes itself on its customer-focused approach to developing new products, and the F6 product is no different. The F6 elevator drive incorporates the best qualities from the F5 — such as its LCD operator parameter structure — while adding new features for customers. Its functional safety STO, multi-encoder technology, open-loop control of permanent magnet motors and dedicated brake control module will make the F6 an excellent drive choice for the elevator market.

KEB has committed to supporting the North American market for years with a building expansion completed in 2019. The 150,000-ft2, ISO 9001:2015-certified facility allows increased inventory, manufacturing and R&D capability to support KEB’s entire product portfolio.

Get more of Elevator World. Sign up for our free e-newsletter.