A review of what is needed from the industry’s workforce today

An Attractive Industry?

All European engineering industries complain of the difficulty to recruit young mechanics and technicians. The problems are well identified: in the eyes of young students, the image of these industries – the elevator and escalator sector included – is that of a dirty, greasy, “old industry,” where work is very physical in all weather conditions. It doesn’t make them dream, contrary to careers in the telecom or computer industries, perceived as sectors of the future. Our industry can do better to recruit the best. We are not an industry of the past; rather, the technological content of an elevator and its traffic modulation patterns are impressive.

The other recurrent problems in some countries are the inadequacy of courses, compared to the requirements of recruiting companies, and the absence of a specific curriculum in technical colleges. But these two main issues are not the only recruitment hurdles for companies in our field. Contrary to the North American job market, which is fairly similar from Vancouver to Miami and where everybody speaks the same language, the European Union (EU) is splintered in 27 member states, with different languages, cultures, legislations and job requirements. Add to the picture countries such as Switzerland and Norway, or those on the fringe of the EU with strong economic relations, such as Turkey or Ukraine, and you get a very complicated picture.

Migratory Work Forces

Over the last few decades, the process of European integration has meant important “working population” moves, where young professionals from the ex-communist states migrated west for immediately better salaries. University graduates from Poland or Hungary were even taking up unskilled jobs in the construction sector in “old Europe,” because they were simply much better paid than for a skilled job at home. The lift and escalator companies – like many others – had to tackle the difficulty: British firms, for example, recruited Polish workers (despite their sometimes poor English), while Polish companies complained about the disappearance of their skilled mechanics, who had moved west for better pay. In January 2007, the European Commission reacted by imposing restrictions on work abroad for the citizens of new member states. These restrictions were lifted at the end of 2011, except for Romanian and Bulgarian workers, who will need a permit to work in some European countries until December 31, 2013. The countries affected are Austria, Belgium, France, Germany, Ireland, Luxembourg, Spain, Netherlands and U.K. Norway and Switzerland keep full restrictions, at least until the end of 2016.

This migration within Europe was actually less important than originally feared. With the present lingering economic crisis, the number of jobs offered has declined, and the problem has subsided. On the other hand, the economy is improving rapidly in Poland, the Czech Republic and other former communist bloc countries. Salaries have increased, and the westward attraction is much less evident for young technicians. Skilled Bulgarian and Romanian mechanics are still tempted, however, since job restrictions were lifted in most European member states. Even where restrictions still apply, though, many jobs in the construction sector remain in high demand for both skilled and unskilled workers.

This leaves elevator companies with two main questions:

- How to make sure there will be a constant flow of young, specialized mechanics who at least know the basics of elevator and escalator technology before beginning further in-house training?

- When hiring nationals from other countries, how can their knowledge level be assessed? Can each young person rope a car or maintain a machine-room-less elevator? One cannot simply assume “Yes” for an answer, especially if the applicant barely speaks the language. It is, above all, a matter of safety.

Training the Technicians of the Future

Each European country faces the challenge differently. Germany champions a “dual” culture of training at school and on the job. In France, a network of technical colleges recently created a curriculum specifically for elevators, with harmonized programs, awarding a Lift Technician diploma in two years. The arrival of this increased the number of new dedicated technicians on the job market at the right time to absorb the much increased order books, with the French legislation on the safety of existing lifts imposing a major upgrading of the existing elevator stock in three periods of five years each, starting in 2004. The U.K. has established a unique system of “on-the-job” training run by the British Lift and Escalator Industry Association (LEIA).

The Original British Vocational Training System

LEIA’s vocational system is intended to complement schools’ teaching and improve mechanics’ competencies. The national vocational training, recently renamed “Qualifications Credit Framework,” recognizes LEIA as the approved assessor, which issues the certificates in three qualification levels: diplomas in Elevator and Escalator Installation and Commissioning, Engineering Maintenance, and Inspecting and Servicing Lift and Escalator Equipment. These ensure individual, on-site, step-by-step training.

Workplace observation is done by seniors and complemented by a portfolio showing evidence of the work done and techniques mastered. Many people of all ages enter the scheme and join the elevator industry, some coming from completely different industries. It is a great recruitment tool for the elevator industry, and recognized and used by companies in LEIA, both large and small. The system improves personal development by identifying skill levels. It is also integrated into U.K. standards. For the elevator industry, it ensures a regular flux of motivated technicians, who share a similar level of knowledge.

The Polish Option

In Poland, PALM (Polish Lift Association) and the Warsaw Education Authority’s Education Department Deputy Director Mieczysława Nowotniak have created a new curriculum for elevator mechanics. It takes some 210 hr. to train these future elevator technicians using a mix of school and practical training prepared in active collaboration between the industry and Warsaw Education Authority to make it fit the needs of the companies and the market’s latest technological developments.

The expected effect of the Warsaw Education Authority’s cooperation agreement with PALM for the lift industry is the realization of “new opportunities, new qualifications through lift maintenance specialization” to better fit with the labor market’s needs. Other sectors signed the same agreement with the ministry in a series of similar pilot projects. The project is co-funded by the European Social Fund in the framework of the “Human Capital Operational Programme Priority” of the European Commission.

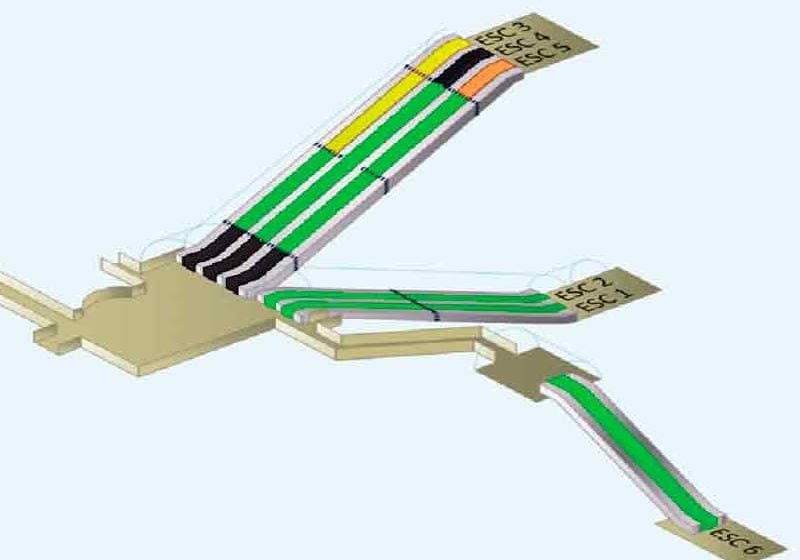

The general objectives of the project are evident: modernization of teaching to better fulfill the needs of the lift industry, creation of a new lift maintenance specialization in the fields of mechatronics, electronics and electrical engineering, and improvement of the qualification of the youth and their employability. Three school sites were involved, with 30 teachers and lift-company specialists, addressing 45 pupils for a total of 210 hr. of practical learning. The program’s 10 modules are focused on all facets of maintenance, and health and safety rules. It also touches on platforms and other devices for the disabled, ending with an examination by UDT (Polish ministry of economic affairs inspectorate).

It must be stressed that equipment used in the training (a lift simulator, for example) was given by lift companies and acquired through EU funds. The first results were visible on the day of the European Lift Association (ELA) conference at the General Assembly in Warsaw: the first group of students received their UDT diploma from the Polish officials and President Michel Chartron of ELA. This first group is expected to be followed by other groups each year to ensure the Polish lift industry can recruit young mechanics who know their trade.

A Solid, Harmonized Knowledge Base for All?

These two original examples in the U.K. and Poland, show that education systems in the 27 European countries are very different from each other, but that each country and association tries to improve the adequacy of education and qualification needs of the elevator industry. The increasingly mobile and migrating work force makes it important for the elevator industry, at the continent level, to simply “know” the level of qualification of each individual. Competence is closely linked to safety, not only of mechanics working on site or maintaining an elevator, but also of the general public, who use it more than one billion times a day in Europe. The ELA intends to identify all systems and harmonize them to help the elevator industry be attractive, recruit the best and optimize its training. The task may be huge, but strides are being made.

Get more of Elevator World. Sign up for our free e-newsletter.