Optimized Elevator Brakes for the New Standards

Oct 1, 2025

Revolutionary new system from mayr minimizes noise and maximizes safety.

by Alexander Hutler and Sebastian Steinart

This paper was presented at Elevcon 2025 in Lisbon, Portugal.

Abstract

Wherever people are transported by elevators, passenger safety is the top priority. Safety-relevant components such as elevator brakes must therefore meet the highest quality requirements. In addition to safety, the focus in an elevator is always on the noise level, especially with brakes. The number of international manufacturers of elevator brakes is small, but the market offers various noise-damping concepts with elevator brakes. A new, revolutionary damping system from mayr® power transmission of Germany not only makes the brakes quiet as a whisper, but also has a decisive side effect: It ensures more stability and, under certain circumstances, more safety over the entire service lifetime. It enables reliable, intelligent and innovative brake monitoring — without any additional sensors. This monitoring not only helps reduce — or even completely avoid — errors and downtime, but also supports demand-based maintenance of elevators in line with the workload and automated remote maintenance.

1. Introduction

Passenger elevators are still one of the safest means of transportation today. The low number of accidents involving passengers in accident and malfunction statistics confirms that high-quality technical products, especially safety components that must pass a notified body (NB) process, are reliably tested in advance.[1] This is particularly true for the safety of fail-safe brakes used in elevators. This is why leading manufacturers take great care to ensure their safety brakes meet the highest quality requirements. Among other things, many leading manufacturers carry out a 100% final inspection before delivery, during which all important technical properties are recorded, documented and permanently assigned to the serial number. The delivery status of each individual brake can therefore be traced back and documented at any time. These data sets ensure the quality standard is maintained throughout the series, as safety does not allow for any compromises. In addition, the safety brakes must be prototype-inspected by the NBs.

2. Background: Brake Solutions in the Past and Today

Geared traction machines with traditional drum brakes (brake solenoids) have dominated the elevator market for many decades and are still on the market today (Figure 1, left). Modern machine-room-less (MRL) elevator installations require compact and low-noise machines and brakes. Further, gearless technology has not only taken the majority share from traditional geared machines, but belt solutions (versus ropes) have become more popular in the market today (Figure 1, right). Higher speeds of up to 10 m/s on specific high-rise elevators have been realized in famous buildings.

Changing conditions impact the design requirements of several safety components, especially brake designs.

2.1. Requirements For Brakes Following European Market Standards

- Dual-circuit brakes (double shoe type) in traditional fail-safe, spring-applied drum brake designs were required by the standard for many decades already, but many of them were realized with a single brake solenoid only.[2]

- An upgrade like retrofitting of micro-switches to such old models increased brake safety.

- Unintended car movement/upward elevator overspeed protection requirements have put the whole system at a further safety level per EN 81 A3:2009.

- The new EN ISO 8100, to be launched at the end of 2025, includes new requirements for brakes. On the other hand, switchless brake technology with an innovative monitoring device as part of a package that comes with the brake will realize the next level, allowing predictive maintenance.

2.2. What Else You Should Take Into Consideration When Selecting Safety Brakes for Elevator Traction Machines

Incorrect selection or dimensioning of brakes can lead to serious injuries and/or damage to property. That’s why it is essential for all parties to take a critical look at technical product details and the performance spectrum when selecting elevator brakes. In all-important industrial sectors where humans and machines work closely, but especially in the elevator industry with passenger transportation, we need to have the highest safety standards.

If, for example, a power failure occurs during a process, the elevator cabin must be held during the e-stop accurately so people are not harmed in any way. Therefore, it is important to permanently exclude the risk of an inadvertent dropping of loads, as well as unpermitted long stopping distances, already in the design phase.[3] Decisive for this purpose is the correct selection of safety brakes, as well as their proper integration into the overall system.

2.3. Safety Due to the Failsafe Principle in Product Construction

Besides some hydraulic brake solutions for high-rise buildings, electromagnetic spring-applied safety brakes according to the fail-safe principle are the first choice for elevator applications, as with these brakes brake torque is applied in de-energized condition (Figure 2). Such brakes provide the required braking torque even in the event of an emergency stop, a power failure or an interruption in the power supply caused by cable breakage, for example.[4] To ensure the safety brakes also provide sufficient friction and work in emergency-stop situations with a defined braking torque, a friction lining developed for this purpose with a corresponding steel counter-friction surface is required. While a quick torque check performed by clients is common with new elevator brakes, an adequate lifetime test wasn’t often realized during qualification. But friction combinations, especially in low-cost brake designs, often reach their tribological limits under certain conditions, like aging and in special ambient conditions. Brakes from global acting experts with years of experience are approved in the market under all conditions.

2.4. Checking Application Conditions Carefully

It is important to carry out an adequate qualification test and define the application conditions of the brakes precisely before making a selection. Therefore, users should define requirements for the brakes as precisely as possible based on the technical data of their traction machine and the elevator constellation. In addition to a lower or upper torque limit and the ambient temperatures, this also includes the number of dynamic-braking action scenarios or special requirements on the installation space. Here, a brake manufacturer’s technically sophisticated standard modular system can provide support and guidance.

3. Quiet and Consistently Safe Over the Entire Service Lifetime; Noise Emissions Well Below 65 dB (A) up to 5 Million Switching Cycles

In addition to safety, the noise level of elevator brakes also plays an important role in ensuring traction machines are user-friendly when installed directly in the elevator shaft. Such an installation is called an MRL elevator design. The noisedamping systems in a brake are force components that can contribute to the force effect of the safety mechanism. It is therefore all the more important that this force contribution is stable and remains consistent over time. Otherwise, safety reserves must be taken into account over the service lifetime. For this reason, experts and engineers from R&D departments of leading manufacturers are constantly further developing the damping systems of their brakes and offering new, technologically advanced solutions. After all, it is important that elevator brakes reliably provide safety in every operating state and that switching noises are practically non-existent — not just when brakes are in new condition, but over their entire service lifetime. Long-term tests confirm that mayr brakes, for example, still operate at a low noise level below 65 dB (A) even after several (up to 5 million) switching actions, and that the required consistency of the safety system is not affected. This is made possible by, among other things, a new, patented damping system based on the special geometry of the brake’s armature disk.[5] This is a new selection option in addition to the existing patented adjustable elastomer damping and provides additional benefits.

4. Metal-Damped Safety Brakes Provide Temperature Stability Compared to Elastomer Materials for a Longer Service Lifetime and Improved Safety

Many damping systems in elevator brakes based on elastomer materials are prone to aging due to the effects of temperature and heat. This can lead to a deterioration in noise development over time and, if dimensioning criteria are not adequately taken into account, may even result in safety risks.

Against the background of the new EN ISO 8100-1/2, standards committees are currently discussing daily brake force measurements that are intended to contribute to greater safety. Under certain circumstances, this can lead to increased downtimes for elastomer systems as they age. Common elastic noise-damping systems such as simple O-ring dampers without adjustment options should therefore only be considered for elevator brakes if increased dimensioning parameters are taken into account.

Existing European standards EN 81-20/50:2020, which will also be replaced by the new EN ISO 8100-1/2, must also be taken into account. Daily brake-force monitoring can ensure quality levels and reveal weak points in the damping system.

Mayr has opened up new possibilities with the new integrated metallic damping system in its elevator brakes. The new system is particularly durable and insensitive to low and high temperature, as it is metallic/mechanical. While changes occur in elastomers/plastics due to extreme temperatures, the modulus of elasticity of the metallic damping system is always the same (between 0° and 80° C). Mechanical adjustment is not required.[5]

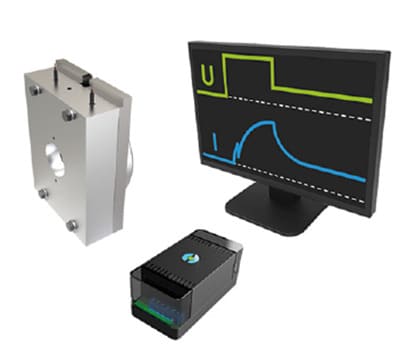

5. Intelligent Brake Monitoring Without Additional Sensors

Thanks to the new, innovative metallic damping system, reliable intelligent brake monitoring is now also possible without additional sensors. Particularly in elastically damped systems, continuous monitoring is possible only to a limited extent. Temperature and aging effects of the elastomers lead to varying current and voltage curves and contribute to error detection and failure of monitoring systems. This monitoring takes place in combination with the metallic dampers with the retrofittable ROBA® brake-checker® module, which mayr has been offering as an intelligent solution for sensorless monitoring of electromagnetic brakes for years. This module works without a sensor but uses the brake as an electromagnetic actuator itself as a “sensor.” The ROBA brakechecker analyzes the physical transformation processes inside the brake, i.e., the transformation from electrical to magnetic and then to mechanical energy. These processes can be identified by evaluating the current and voltage.

6. Software Package: Technology as an Integration Option in Controls Systems

Users are able to integrate the module easily and quickly into machines and systems without having to intervene in the converter or control components. However, as a special option, it is possible to integrate the existing ROBA brake-checker software (instead of the hardware module) into the client’s control system, which can be considered especially for large quantities. This can be done in the context of co-operations, for example. The brake supplier can draw on decades of experience in the field of brake monitoring and can contribute the necessary technology for integration directly into the client’s control system, if required.

7. Reducing Costs With “Talking” Brakes

The ROBA brake-checker module, which is clamped into the voltage supply of the brake, detects movement of the armature disk through extended analysis of current and voltage, and knows the condition of the brake. In addition to monitoring the switching condition and critical coil temperature, the ROBA brake-checker also performs preventive function monitoring for wear, functional reserve and malfunctions. This means processes can now also be evaluated, anomalies in the process can be detected quickly and conclusions can be drawn from complex inter-relationships. Also, integration into remote maintenance systems is possible. This means maintenance becomes plannable: The elevator operator or manufacturer is able to undertake maintenance in a targeted and aligned manner. This creates potential savings, not by using low-cost components, but by saving on time-consuming and costintensive services. The module itself is now able to provide detailed information on the condition of the brake. In some countries, regular maintenance procedures must be carried out by service personnel, and the results are documented manually. If such visits and service work are no longer necessary, customers (i.e., building owners) are able to save a lot of money. To achieve this, however, procurement costs and service costs must be combined.

8. Condition Monitoring Without Switches: Reliable Monitoring Independent of the Location of Use

As the ROBA brake-checker works without sensors — i.e., no microswitch or proximity switch has to be attached to the outside of the brake for switching condition/release monitoring — simplified safety brakes in a basic design can be used and smaller air gaps can be considered optionally on such brake designs.

In contrast to the solution with micro switches, which are exposed to impacts and vibrations due to their installation situation on the brake, monitoring with the external ROBA brake-checker is carried out from the control cabinet, i.e., in a protected environment. Failures due to special ambient conditions and error signals because of dirt (such as friction dust) are thus excluded.

It is important that elevator brakes reliably provide safety in every operating state and that switching noises are practically non-existent.

9. Conclusion

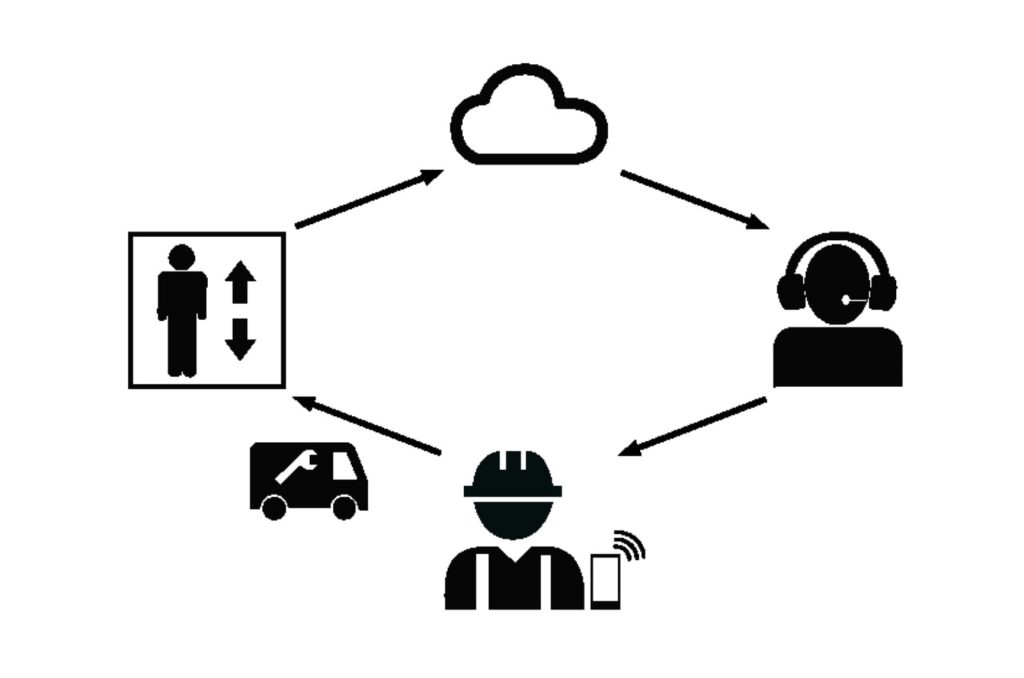

Permanent status information of the core components, demand-related maintenance (plannable and suited to the actual frequency of use of the elevators), automated remote maintenance and cross-elevator/cross-building error analyses are the key aspects of tomorrow’s elevator maintenance (Figure 4). Leading manufacturers offer solution concepts for the predictive maintenance of electromagnetic elevator brakes based on permanent status checks. The focus here is placed on the ROBA brake-checker module, which in the basic module version is not only able to monitor and supply brakes without the use of sensors. In an advanced version, it also provides data, thus ensuring intelligent safety. This means that technical trends can now also be evaluated, anomalies during application operation can be detected quickly and conclusions can be drawn from complex interrelationships. For users, this means plannable and cost-effective maintenance and maximum system availability. This module is a suitable technology for a new generation of elevator brakes and has been tested in the market at many different branches.

Finally, the safety of the passengers has top priority. Every single component, especially the integrated safety brake of an elevator traction machine, should attract interest because safety-relevant components such as elevator brakes must fulfill the highest quality requirements. However, due to intensive global competition in the elevator industry, price repeatedly plays a primary role, even for safety-relevant components. Despite this market situation, a well-founded selection of reliable products must be made since safety does not allow for compromises.

References

[1] TÜV-Verband (2024, June 13). Anlagensicherheitsreport 2024. tuev-thueringen.de/blog/anlagensicherheitsreport-2024-gutjeder- zehnte-aufzug-hat-schwere-maengel

[2] Brooks, Dru (2025, February 17). Elevator Code Compliance – Elevator Brakes. NYC Mandatory Elevator Safety Code Compliance, Section 3.8.4.1 Single Plunger Brakes. libertyelevator.com/blog/elevatorsafety- code-compliance-elevator-brakes

[3] Hutler, Alexander (2013). The electromechanical lift brake. In Volpe, G. (Hrsg.), How it works (3. Auflage, S.56-63). Volpe Editore S.r.l.

[4] Bestle. H. et al. (2014). Elektromagnetische Sicherheitsbremsen, Die Bibliothek der Technik. Süddeutscher Verlag onpact GmbH.

[5] Fichtl, Michael, (2018). Bremse mit integraler Dämpferstruktur (DE 10 2018 008 899 A1 2020.05.14). Deutsches Patent- und Markenamt. depatisnet.dpma.de/DepatisNet/ depatisnet?window=1&space=main&content= captcha&action=pdf&docid= DE102018008899A1&xxxfull=1

Alexander Hutler works at mayr power

transmission, a Germany-based international

manufacturer of safety brakes. In 1992, he

joined Mayr and worked in many different

areas of responsibility. Since 2006, he has

been part of global key account management

for elevator brakes, leading numerous

international OEM projects. mayr power

transmission is well-known as a leading

manufacturer of elevator brakes and holds

numerous patents in this field.

Sebastian Steinert works at mayr power

transmission. He is part of global key account

management for elevator brakes and has led

international OEM projects.

Get more of Elevator World. Sign up for our free e-newsletter.