Your authors elaborate on the company’s evolution and growth story.

by Ashish Patel and Alpesh Patel

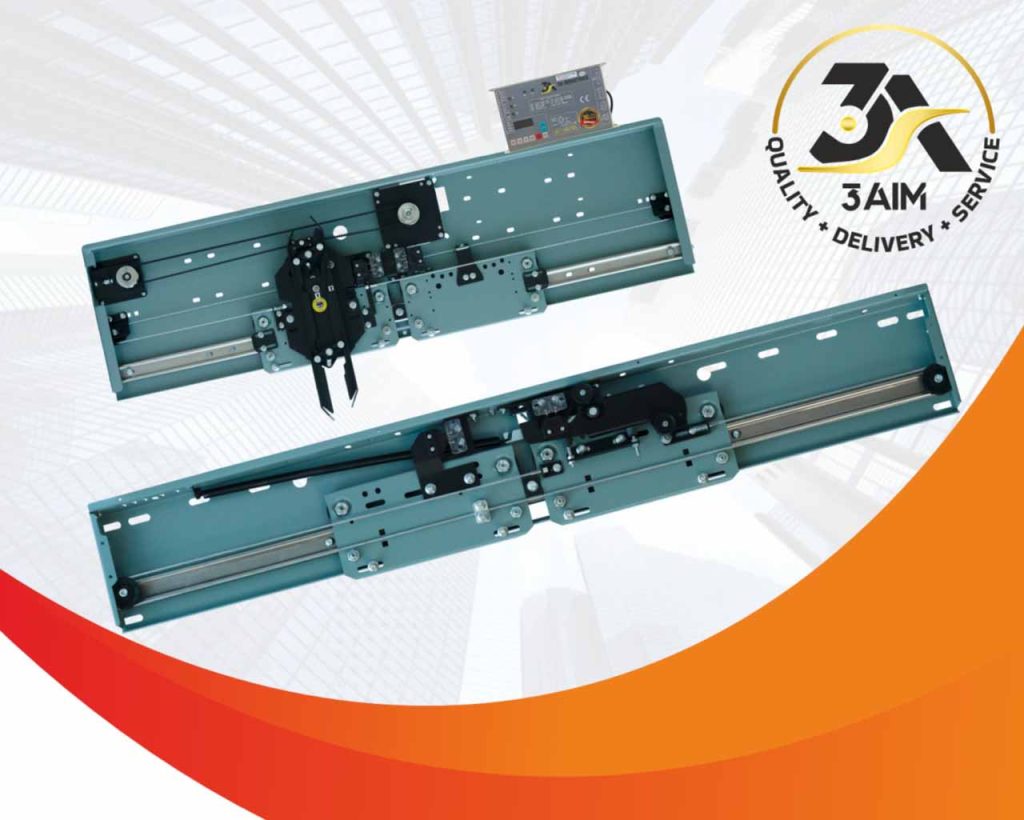

3A Industries was established in 2019. We have been in the technical field for the last 15 years after deciding to provide a safety-oriented product to the elevator industry. At that time, we considered one of the key components of an elevator, which was the elevator auto-door operator, and began with that.

Our management team has a good blend of experience and expertise: We are four brothers heading this business, managing different areas. Ashish Patel has done B.E Mechanical and look after the sales and marketing departments, and Alpesh Patel has a diploma in mechanical engineering and manages the finance and purchase responsibilities. Amit has done I.T.I Fitter (all-India first) and Nikunj Patel has a master’s degree in pharmacy; they both manage production and dispatch-related aspects of the company.

3A Industries always works toward three aims: quality, delivery and service. With our expertise in engineering and quality assurance, we aim to make the elevator and escalator industry safer for all passengers.

Currently, we have a 3000-ft2 area with three different units, two laser machines (1 kw and 3 kw), two bending machines, a press machine, a riveting machine, a packing machine and one goods assembly unit. Our production range is from 500 to 1,200 center-opening and telescopic auto-door operators in two panels. We also manufacture three-panel, four-panel and six-panel doors.

In this domain, we offer optimum quality products to our customers. These are highly recognized by customers for their accurate dimensions, high strength and sturdy construction. Our clients can avail these products from us as per their needs and demands, as we are offering these products in varied specifications and also in customized form. We offer these products at leading market prices within the assured span of time. Our monthly sales are 30,00 landing headers and 700 car door operators. We have a 98.7% repeat ratio of customers.

We are assisted by a team of skilled and proficient professionals, which puts in its best knowledge to offer a wide range of elevator spare parts and accessories. The team members have experience in their respective fields. To choose the best professionals for our company, we take a test of their experience, expertise and educational qualification before hiring them. Our workforce puts all its efforts to offer products without defects that fulfill market demands in an efficient manner. Moreover, we organize seminars and workshops time to time for updating the knowledge of our professionals.

They work in full coordination with each other, as well as with clients, and ensure an optimum level of customer satisfaction. We invest regularly to upgrade our facility so we can keep pace with ongoing market trends and developments. With the help of our production unit, we have been able to cater to bulk demands of products within the promised frame of time. Also, we are accepting multiple modes of payment, keeping customer convenience in mind.

Being a client-centric organization, we are completely devoted to offering and maintaining optimum quality in our range of elevator parts. In this regard, we make sure to utilize superior raw material procured by authentic and loyal vendors. Moreover, our in-house quality rigorously tests the range for key parameters.

Currently, 3A Industries is growing in the market at a very fast speed and competing with top brands. The company is exporting to several countries like Dubai, Africa, Nepal and Sri Lanka. Our vision is to join with a multinational corporation (MNC), which will create a greater impression of our products in the market. We are working on Bureau of Indian Standards approval, which we expect to be complete within a couple of months. Our next step is to set up a bigger factory — approximately 60,000 ft2 — within one and a half years.

Get more of Elevator World. Sign up for our free e-newsletter.