A Gearless Future

Aug 4, 2024

Nayan Movaliya (NM), director, Tectronics Engineers, provides perspectives to your author (SSP) on the company’s latest innovation, the RTG 32P 0606 Model, and how it will advance the VT industry.

SSP: What are the significance and prospects of gearless elevator machines for the vertical-transportation (VT) industry?

NM: Gearless elevator machines represent a significant advancement in the VT industry due to their ability to provide smoother rides, improved energy efficiency and enhanced environmental friendliness. As the industry continues to prioritize sustainability and efficiency, the demand for gearless technology is expected to grow, offering substantial long-term prospects for innovation and adoption.

SSP: What are the latest innovations introduced by your company that will contribute to the advancement of the VT industry?

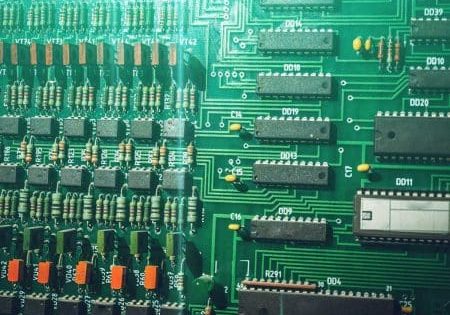

NM: Our latest innovation is the RTG 32P 0606 Model, a patented product with advanced technical specifications. It offers exceptional speed and operational excellence, setting a new standard in the industry.

One of its key features is its low voltage requirement in the technical segment, which provides significant advantages. Additionally, its 32-Hz frequency and 32-pole configuration further enhance its technical capabilities, making it a groundbreaking product in the VT sector.

SSP: What are the recent advancements and trends in elevator machines? Are there any innovative products recently introduced by your company that feature the latest technological advancements or are built with modern engineering methods?

NM: In the realm of elevator technology, recent advancements have focused on optimizing efficiency, safety and environmental sustainability. The future of elevator systems lies in the development of high-speed elevator machines specifically designed for high-rise structures. Our R&D team is committed to enhancing the speed of our gearless elevator machines to meet this growing demand. Through ongoing innovation, we are diligently working toward increasing speeds from 2 m/s to 3 m/s.

SSP: What is the significance of manufacturing in India? Does this enhance the company’s ability to offer the most cost-effective solutions and superior service to its customers?

NM: Manufacturing in India allows us to leverage local resources, skilled labor and cost-effective production methods. This not only enhances our ability to offer competitive pricing but also ensures that we can provide superior service through a localized supply chain. By manufacturing in India, we are able to respond quickly to market demands, customize solutions for regional needs and support the local economy, all while maintaining high standards of quality and performance.

Additionally, we are proud to announce that we are offering a five-year warranty on all our products, underscoring our commitment to durability and customer satisfaction. This warranty reinforces our confidence in the reliability and longevity of our products, providing our customers with peace of mind.

SSP: What are the strategies implemented by your company to remain competitive in the market while also ensuring that high-quality services are provided to your customers at economical prices?

NM: To remain competitive, Tectronics Engineers focuses on continuous innovation, quality control and customer-centric solutions. We invest in R&D to stay ahead of industry trends and implement advanced manufacturing processes to ensure product excellence. Additionally, we prioritize customer feedback and tailor our services to meet their specific needs, providing economical yet high-quality solutions. Our commitment to sustainability and efficiency also helps us deliver value to our customers while maintaining cost-effectiveness.

SSP: What is the significance of modernization in elevator machines? And why is it necessary for the VT industry to consistently adopt specific measures to upgrade elevator technologies?

NM: Modernization in elevator machines is crucial for improving safety, efficiency and user experience. As buildings become taller and more complex, the demand for advanced VT solutions increases. Modernization allows for the integration of the latest technologies, such as energy-efficient motors, smart controls and enhanced safety features. For the VT industry, adopting these measures is essential to meet regulatory standards, reduce environmental impact and provide reliable and efficient transportation solutions that keep pace with the evolving needs of modern infrastructure.

The benefits of Tectronics Engineers’ gearless technology are as follows:

- Gearless Technology: Provides smoother rides, improved energy savings and enhanced environmental friendliness.

- No Machine Room Required: Lightweight and space-efficient, requiring less structural support and offering easier access for maintenance.

- Energy Saving: Utilizes optimized power factors to reduce power consumption and heat production with energy savings of up to 40% compared to conventional geared elevators.

- Noise-Free Operation: Operates without vibration or noise, ensuring a peaceful and comfortable ride.

- Compact Size: Eliminates the need for a traction machine gearbox, minimizing space requirements and optimizing design efficiency.

With these advantages, Tectronics Engineers continues to lead the industry in providing innovative and efficient elevator solutions that meet the evolving needs of customers and the VT market.

About Tectronics Engineers

Get more of Elevator World. Sign up for our free e-newsletter.