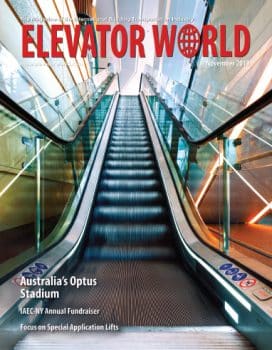

A Panoramic Incline

Nov 1, 2019

thyssenkrupp improves accessibility for a port with a sleek and modern design using an MRL elevator.

Installation of an inclined panoramic elevator with a nominal load capacity of 1150 kg (15 people) in Puerto Viejo in Getxo, Spain, between existing parking on Muelle Ereaga and Ribera streets posed an interesting challenge for thyssenkrupp.

The solution proposed to facilitate access to the area is a machine-room-less (MRL) panoramic elevator with a constant and rectilinear 74° inclination. It also features a double entrance at 180°, two stops, a travel height of 15.4 m and a gangway at the upper landing to provide access to the Ribera Street sidewalk. Additionally, the elevator includes air conditioning equipment and video-surveillance cameras. Also, for maximum integration of the elevator with its surroundings, extensive landscaping was added. This helped the elevator integrate completely into the landscape, facilitating access for all users and enhancing the commercial and tourist area. It is equipped with a remote-monitoring system and thyssenkrupp’s cloud-based predictive-maintenance solution, MAX.

Getxo is a coastal municipality with a population of about 80,000. It is located 14 km from Bilbao in the province and historical territory of Vizcaya near Bilbao estuary at the mouth of the Ibaizábal-Nervión River. The complex orography boasts cliffs and numerous beaches (Las Arenas, Ereaga, Arrrigunaga, Azkorri-Gorrondatxe, Barinatxe, La Bola, Tunelboca and Puerto Viejo). It also has a marina for cruise ship docking, hotels, leisure and cinema services, as well as the Puerto Viejo of Algorta, which features traditional bars and restaurants.

Puerto Viejo is emblematic and highly visited, so demands and requests from residents and tourists to improve access to the area constantly increase. That is why the installation was included in the “Mechanical Improvement Project for Accessibility in the Puerto Viejo of Algorta (Getxo)” of the Getxo City Council.

The cabin of the lift features a panoramic glass enclosure made of stainless steel with materials suitable for an aggressive saline environment.

Prior to the execution of the project, access to Puerto Viejo was from Aretxondo Street, through a steep longitudinal slope via stairs or by the existing walkway at the edge of the sea from the beach of Ereaga. Where the elevator’s lower landing is now, there was a parking lot without a sidewalk where the cars parked sideways, while the new upper stop was a pedestrian promenade.

The existing pedestrian promenade at the end of Ribera Street on the upper part of this facility has been improved, and it connects directly with Usategi Park. The elevator runs through a completely covered shaft consisting of a reinforced concrete pit at the lower landing and a stainless- steel marine-grade tubular structure. The shaft is also covered with glass panels, to create a panoramic transparent effect. At the height of the upper board, the metal structure of the shaft connects with a metallic, covered glass walkway, which gives access to the pedestrian promenade.

Technical Characteristics

- Type of elevator: Panoramic inclined elevator in glazed shaft

- Nominal load: 1150 kg

- Number of passengers: 15

- Inclination: 74° (constant and rectilinear)

- Speed: 1.6 m/s

- Stops: 2

- Number and disposition of entrances: Double entrance, 180º

- Travel height: 15.4 m

- Total travel time: 10 s

- Nominal power: 14.9 kW

- Cabin dimensions: 2,530 X 1,440 X 2,040 mm.

- Traction ropes: Six 10-mm diameter Drako 300-T high- resistance ropes

- Cab guide rails: Two International Organization for Standardization (ISO) profiles T90/B with brushed guide rails

- Counterweight guide rails: UPN-140 laminated profile as counterweight truss and ISO T90/B brushed guide rails serving as anti-tip guide railing

- Buffers: Energy dissipation type (two for cabin and one for counterweight)

- Type of shaft enclosure: Stainless-steel tubular hollow profiles SHS 180X6 and SHS 120X6, with the entire structure enclosed by glass panels

Cabin Type

The cabin of the lift features a panoramic glass enclosure made of AISI 316SB stainless steel with materials suitable for an aggressive saline environment and 6 + 6 safety glass. It includes a stainless-steel handrail, slip-resistant rubber floor, a bidirectional emergency system, LED lighting spots, an emergency light, air-conditioning, overload signaling and an alarm button. The stainless-steel push button is located at a maximum height of 1,200 mm.

Traction System

The electric lift is roped 2:1. It includes three-phase traction control with a frequency and voltage inverter to ensure a smooth performance. It is asynchronous gearless and has a traction sheave with hardened grooves.

Floor and Cabin Doors

The lift has two automatic, 1,000-X-2,000-mm center-opening glazed doors and frames in AISI 316SB stainless steel. It is also equipped with an electromagnetic lock that prevents the doors opening during travel.

Signaling and Control

The unit is equipped with Braille electromechanical anti-vandal push buttons and call recording lighting on the stainless-steel push-button panel, as well as a stop selector.

The cabin signaling system consists of alarm push buttons, open doors with call register, an electronic position and direction indicator, optical and acoustic overload signals, and an alarm and emergency lighting for a minimum of 60 min. The landing signal system has a waterproof anti-vandal button with a call register and 3.2-in. thin-film-transistor displays in the hall door lintel.

Safety and Protection

The electronic control system for the lift is CMC4 + 20/50 with IP-54 protection with microprocessors, including a 24-h communication system and a remote monitoring system connected to the cloud by MAX. It also includes an automatic rescue system and a control cabinet at the upper landing with the control system and frequency inverter inside. Additional safety features included in the lift are a progressive safety gear activated by a speed governor fixed on the top of the shaft, speed governor rope tensioning pulley in the pit and an emergency stop function integrated into the gearless machine. All elements are marine grade.

The MAX system installed in this elevator makes it the first inclined elevator connected to the cloud. All information is collected in real time and sent to the cloud, making predictive maintenance possible and notifying technicians of needs before an event occurs. Specifically developed algorithms calculate the remaining lifetime of the most critical systems and components of the elevator, recognizing the components and moments at which they need attention.

Get more of Elevator World. Sign up for our free e-newsletter.