STOP and GO in Lengfurt

Your author arrived in Lengfurt, Germany, on one of the hottest days of the year at the invitation of the Professional Association for Wood and Metal (BGHM) to attend the BGHM Lift Symposium on July 2-3 at the Lengfurt Training Centre. There, a mandatory “STOP” was followed by a constructive “GO.” STOP stands for Substitution, Technical, Organization and Personal protective measures and describes the sequence in which hazards should be prevented as effectively as possible in occupational safety. This unique national event brought together experts from all areas of the lift industry to discuss occupational safety and develop practical solutions.

Lengfurt as a Center of Expertise

The BGHM Training Centre in Triefenstein-Lengfurt provided the ideal setting for focused technical discussions. Elevator manufacturers, installation and maintenance companies, independent engineers and testing organizations took advantage of the opportunity to engage in an intensive exchange of experiences. The two-day program followed the proven S-T-O-P principle: substitution, technical, organizational and personal protective measures — the hierarchy of effective occupational safety measures.

STOP: Focus on Accident Statistics

Philipp John of BGHM opened the symposium with current figures on accidents in the lift industry. The analysis covered 311 companies from the lift construction, installation and maintenance sectors from 2022 to 2024. There were 1,288 reportable accidents at work (resulting in more than three days of incapacity to work) recorded. Particularly alarming was that 8% of accidents were falls — a proportion that calls for action from the industry. “Occupational safety requires continuous attention and consistent action,” John emphasized. “Every accident is one too many.”

GO: Developing Practical Solutions

Safe Maintenance of MRL lifts

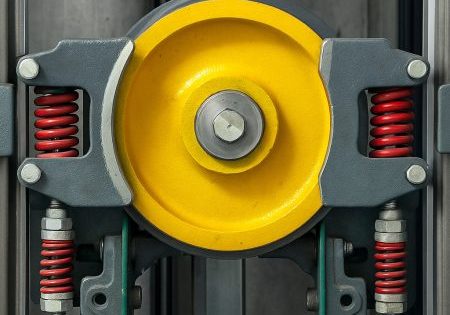

Thorsten Kalweit’s presentation was on “Working on Machine Room-Less (MRL) lifts.” Using practical examples, he raised awareness about the wide range of hazards and highlighted where cost pressures can lead to safety deficits. Problems arise, for example, when inspections are not carried out after changes have been made for cost reasons or when safety systems are tampered with.

TK Elevator (TKE) received special recognition with the Schlauer Fuchs Safety Award for its TKE-STP Safety Transformation Programme — the first safety award for a lift company.

PPE for Fall Protection

Martin Leopold of IKAR GmbH — a wind energy industry partner specializing in safety solutions for working at height — discussed various aspects of personal protective equipment (PPE) and fall protection. His workshop, “Selecting and Using Suitable PPE,” addressed familiar problems and developed practical solutions for everyday work.

Risk Assessments in SMEs

Udo Niggemeier provided concrete assistance for small and medium-sized enterprises (SMEs). His approaches illustrated how even smaller companies can meet German Social Accident Insurance requirements. He summed up the main objective of the Occupational Safety and Health Act in a simple formula: “COME HOME!” His passionate appeal was that occupational safety pays off, both when conducting risk assessments and investing in high-quality PPE.

Special Topics: Scaffolding and Asbestos

As a civil engineer, Kathrin Stocker discussed the requirements for assembly scaffolding and sought to bridge the gap between theory and practice. Dr. Maike Unverferth raised awareness of an often-underestimated risk with her presentation on “Asbestos-Related Occupational Diseases Among Lift Engineers” and highlighted ways of gaining recognition for those affected. Conclusion: Constructive cooperation is needed for greater safety.

The BGHM Lift Symposium impressively

demonstrated that when experienced practitioners, competent speakers and committed participants come together, constructive solutions emerge. The event filled an important gap in the professional landscape with a balanced program of presentations and workshops. According to the BGHM, there have been “no comparable specialist events on occupational safety in lifts” to date.

Impetus for Further Training

As someone who works in further training, your author found this symposium a valuable source of inspiration for curriculum development. Not only current accident statistics, but also the asbestos problem and MRL solution approaches, will be incorporated into future training courses.

Conclusion: Occupational Safety as a Joint Task

The symposium impressively demonstrated that occupational safety in the lift industry is a multifactorial challenge that can only be successfully addressed through a systematic approach and continuous cooperation among all parties involved.

The most important findings at a glance:

- Accident prevention: 8% of fall accidents are 8% too many. SRS (Suspension Relief Stirrup) and fall accidents are the main cost drivers, averaging more than £4,000 per accident, and require priority attention.

- Technical solutions: MRL lifts require specific safety concepts, especially for the shaft head, pit and control cabinet areas.

- Legal compliance: System-specific risk assessments are not only mandatory, but also a practical tool for systematic risk minimization.

- PPE expertise: Choosing the right restraint or fall-arrest system for the situation can be a matter of life and death.

- Quality standards: Installation scaffolding must meet the highest safety requirements; improvisation costs lives.

- Long-term risks: Asbestos-related occupational diseases, which cause more than 1,300 deaths annually, require consistent preventive measures.

The message from Lengfurt was clear: Occupational safety works best when everyone involved works together constructively. The participants — occupational safety specialists, managers and association representatives — took away concrete ideas for their daily work. During breaks and at the joint dinner, valuable contacts were made that will continue beyond the symposium. The symposium showed more “GO” than “STOP” — an encouraging sign for the industry.

Get more of Elevator World. Sign up for our free e-newsletter.