Custom Elevator a Crowning Achievement

Jan 1, 2019

New York’s Hudson Valley is a stunning riverscape of quaint towns and villages nestled among forested hills, a natural wonderland dotted with dream houses a stone’s throw from riding stables and boat landings. Most residents are drawn here for the lifestyle, but when you get right down to it, it’s all about the view. The owners of this architectural gem of a house surely think so. Visitors who ascend to the rooftop patio are awed by the sight: a lush, green vista cleaved by the gently flowing Hudson River.

The house’s four levels — guest space at the bottom, dining and bedrooms on the second, an office on the third and the rooftop patio — are connected by a custom-crafted spiral staircase, an artistic feature in its own right. And, while the homeowners love the staircase, they wanted to make the home more accessible by installing a residential elevator. This proved to be a somewhat tricky proposition, with several options for home additions considered and rejected for various reasons: one choice wouldn’t reach all levels, another wouldn’t blend in with the architecture of the house and yet another would have put the lift opening directly into a bedroom. Adding to the difficulty was the homeowners’ demand that the staircase not be removed, or even modified.

The Creative Vision

When Nationwide Lifts of Fayetteville, New York, was called in, the solution became clear. The four-level spiral staircase rises through a tall, narrow atrium extending to a cupola on the roof. The staircase fills most of the space but leaves a crescent-shaped sliver of space open. This would be the setting for the most creatively designed elevator Nationwide had ever built.

Nationwide proposed a custom elevator of a five-sided design that would fit in the space between the spiral staircase and outside windows. While this would eliminate all the problems related to adding onto the house to accommodate an elevator, multiple challenges remained:

- The elevator must use every inch of available space, following the contour of the windows and staircase.

- The elevator hoistway frame must be self-supporting, as there is no structural wall on which to hang rails.

- The hoistway frame must blend with the architectural elements in the home.

- The panels must be clear to complement the open atmosphere of the home.

- Entrances would be needed on both ends of the space, allowing for access at all four landings.

- The elevator cannot have a pit, as the construction of the bottom landing would not allow one.

In the process of meeting these challenges, Nationwide would file four patents and create the “Crown Jewel” of its Artisan Elevator line.

One-of-a-Kind Shape

The available space was only 34 in. wide and had a clearly unique shape. Sketching out a shape to fit was the easy part. Designing a structurally sound, self-supporting elevator hoistway was much more difficult. Nationwide developed a proprietary means to construct the unusual shape utilizing custom aluminum extrusions and steel ring components. Traditional elevator components (elevator T-rail and winding-drum operation) are integrated into the hoistway frame. Special care was taken to hide fasteners and elevator components. Three of the four provisional patents are related to the design and construction of the hoistway. The final design included a tight, 25-in. distance between guides, a deep cab and 24-in.-wide doors on each end. Though smaller than the typical home elevator, it will still comfortably fit two people.

Pitless Design

Nationwide took the pitless requirement of this project very seriously. The designers knew the right solution could be applied to future projects, so a tremendous amount of time and effort went into this aspect of the project. The fourth provisional patent covers the solution that solved the pitless challenge. This elevator has a floor that is only 3/4-in. thick and can land flat on the bottom floor. There is only a 3/4-in. step up into the cab, a transition easily addressed with a wedged entrance sill. Equally as amazing, this process can easily be applied to other shapes and sizes. This gives the Nationwide Artisan Elevators a new feature for retrofitting elevators into homes.

Remarkable Aesthetics

The assimilation of the elevator into this unique home was a critical part of this project. Color, fixtures, clean lines and even noise level were all very important. A custom powder-coat color was made to match the “Hudson Valley Blue” that was used on steel I-beams throughout the house. The vertical members of the elevator frame line up with the vertical beams that frame the windows of the atrium, allowing the elevator frame to blend with the structure of the house. Stainless fixtures match the modern style of the home.

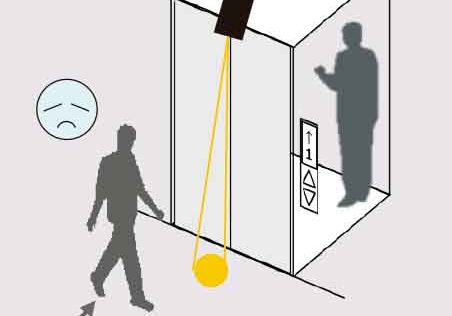

Winding-drum operation, with its inherent simplicity, is the ideal lifting mechanism for this elevator. The motor/gearbox is hidden at the top of the hoistway behind frosted polycarbonate panels. The high-quality motor/gearbox chosen for this application provides nearly silent operation as the cab smoothly travels. Crystal-clear polycarbonate panels fill in the frame of the hoistway and walls of the cab. Custom aluminum extrusions frame the panels with a fastener-free appearance.

Nationwide demonstrated creativity and innovation with this project, and the challenges were met with unprecedented solutions that brought remarkable results.

Credits

Designer: Andy Darnley

Installer and manufacturer: Nationwide Lifts

Drive system: Wurtec

Get more of Elevator World. Sign up for our free e-newsletter.