GSSE 2023 Preview

Aug 14, 2023

Global Stainless Steel Expo (GSSE) set to once again unlock the potential of stainless steel in the vertical-transportation (VT) industry.

After an impressive debut last year, the second edition of GSSE will be held on September 14-16 at the Bombay Exhibition Centre in Mumbai. Among recent additions to the tradeshow portfolio of organizers Virgo Communications & Exhibitions, GSSE has a special significance for the VT industry and is a “must-attend” event for all those who are connected with the stainless steel industry and related processes.

Explaining the importance of the event, Vijay Sharma, director, Jindal Stainless, said:

“As the exclusive title partner for GSSE, we are looking forward to yet again interacting with fellow stakeholders in the stainless steel ecosystem, including suppliers, users, traders, associations, regulators and fabricators. Together with these partners, we intend to leverage this event to discuss issues pertinent to the growth of India’s stainless steel industry and solutions needed to raise the bar for the whole country.”

Stainless steel plays a key role in fabricating the steps used in escalators and moving walkways, as well as the decking and balustrades. From quick and hassle-free installation to eliminating rust, stainless steel is an element that incorporates multiple benefits for all stakeholders, from real estate and infrastructure developers to maintenance teams and end users. Nowadays, all major lift and escalator manufacturers, their partners and contractors offer stainless steel cladding elements and accessories in a wide variety of designs. Stainless steel sheets and plates are used for:

- Elevator doors

- Wall and ceiling cladding of lift cabins

- Floors

- Press plates

- Control and display panels

- Handrail systems

- Architraves

- Shaft cladding

Stainless steel is a suitable material for cladding in the lobby, entrance or reception areas of buildings like residences, hotels, airports, museums, etc. Due to their exposed position and close contact with passengers, lifts are “the business card” of every building. An excellent finish, high-quality materials and an aesthetic and functional surface inside and around the lift give the user an impression of timeless modernity and up-to-date technology and quality, as well as a feeling of comfort and safety. Finishes can increase the image, prestige and value of public or residential buildings, company offices, shopping malls, etc.

Stainless steel in the form of custom-sized sheets, parts or accessories is the ideal material for a variety of applications for elevators and escalators due to several advantages:

- Great resistance to high temperatures, moisture and corrosion

- Attractive, high-quality appearance

- Long service life and durability

- Robustness against mechanical and chemical influences

- Good resistance to weather conditions, UV radiation and high and low temperatures

- Low cleaning and maintenance costs

- Environmentally friendly low water and cleaning agent consumption

- Protective fire-resistant properties

- Sustainable, consisting of 80% recycled material and 100% recyclable itself

It is not surprising that all leading elevator manufacturers use stainless steel material for their passenger and cargo lifts and escalators. Further, its usage in lifts is advised and, in some cases, even required by building regulations in many public areas, private and public residential buildings, offices, shopping centers and medical facilities. When it comes to materials, the most important requirements for the construction of stainless steel escalators are important aspects such as:

- Safety

- Fire protection

- User comfort

- Visual appearance

- Durability

- Hygiene

- Cleanliness

- Ease of maintenance

The metal and surface quality, as well as the design aesthetics, are decisive factors in standing out in today’s competition. Therefore, GSSE has a special significance for the VT industry because stainless steel is extensively utilized in many facets, from the structure of the elevator car to the handrails inside it, the beams above it (crosshead) and the sling extending down, as well as the guide rollers or guide shoes attached above and below it, springs inside that help regulate the speed, wire ropes, landing operating panels and cabin operating panels. Load-bearing steel shafts are preferred for maximizing usage of limited available space, combining functionality and aesthetics.

GSSE is an apt platform that attracts participation of India’s leading stainless steel producers who come together to showcase sustainable business solutions to end-user industries. The event will further augment usage of the metal mainly in India, which is the second-largest consumer of stainless steel in the world.

The expo presents an exclusive opportunity for manufacturers and suppliers of stainless steel products to meet with potential customers representing 200-plus product applications from India and across the globe. GSSE has quickly developed into the largest dedicated stainless steel industry stakeholder event helping end-user industries source and network. Apart from the expo, a concurrent three-day conference featuring 12 power-packed knowledge sessions with 50-plus renowned national and international speakers is expected to draw more than 1,000 attendees from more than 500 organizations.

In many industries, stainless steel is rapidly becoming a preferred material that has replaced conventional materials. The varied properties of stainless steel make it a versatile element used in diverse applications across varied segments. Automobile manufacturers and the railway system, along with the building, construction and infrastructure segments, remain the biggest consumers of stainless steel globally.

Often used in the treatment and design of the external façade of modern buildings, it is a preferred material for the construction of load-bearing structures, supporting components and fittings, bridges and other utilities such as flyovers, elevated roads, metro lines, etc. The clean finish that it offers, ease of maintenance, lack of toxic coating and resistance to corrosion and discoloration are some of the key factors that have contributed to the extensive use of stainless steel in the construction industry.

Stainless steel can be used for kitchen slabs, industrial kitchens, hospitals, partitions and more. When not needed, it can be easily dismantled and recycled without any waste or loss of material or funds. As the use of stainless steel continues to grow, now is the time for manufacturers and dealers of the material to showcase their offerings to potential clients.

Gain insights about stainless steel applications for the VT industry and its inherent advantages at GSSE 2023. To register, visit GSSE Expo website or scan the QR code.

GSSE 2023 Highlights

- B2B exhibition

- 150-plus exhibitors

- Overseas participation

- 10,000-plus trade visitors

- 100,000 ft2 area

- Buyer/seller meet

- CEO roundtable

- Industry and technical conference

- 12-plus knowledge sessions

- 50-plus industry speakers

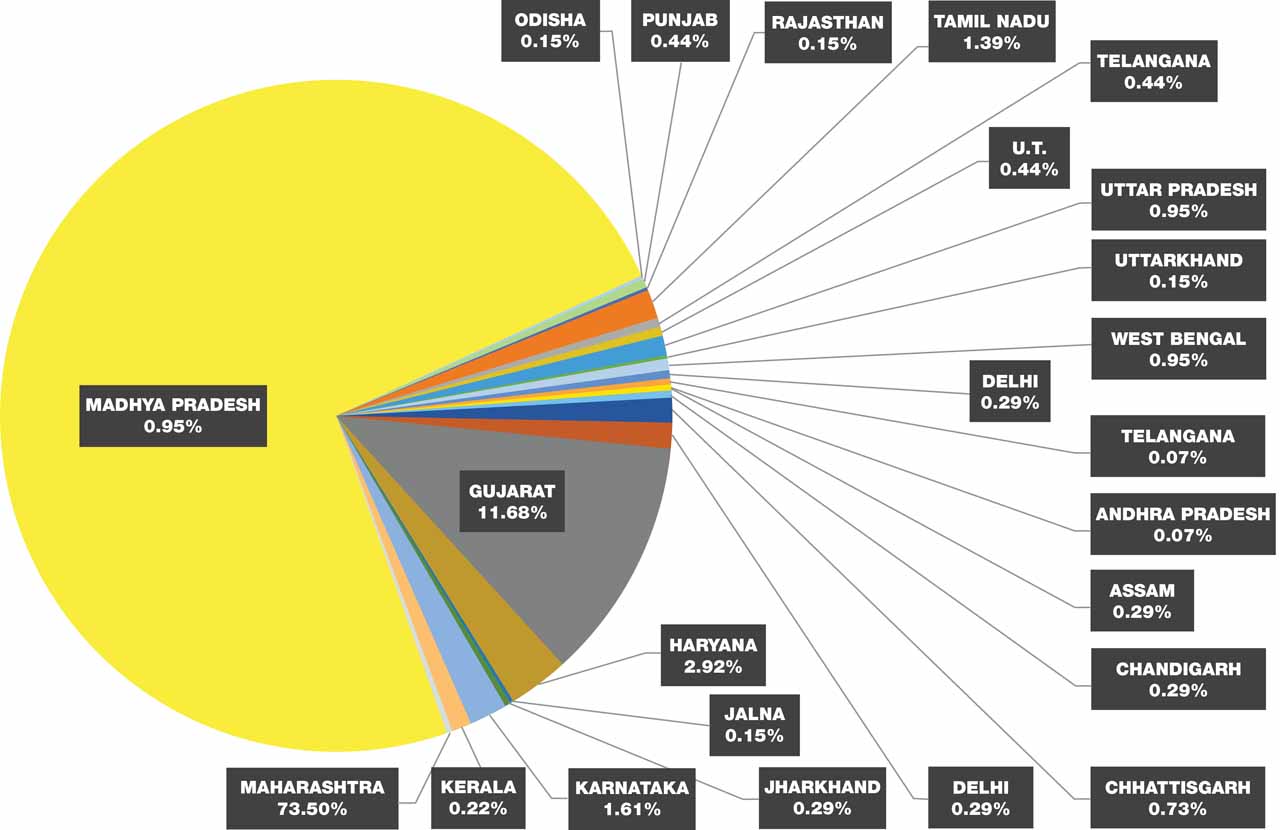

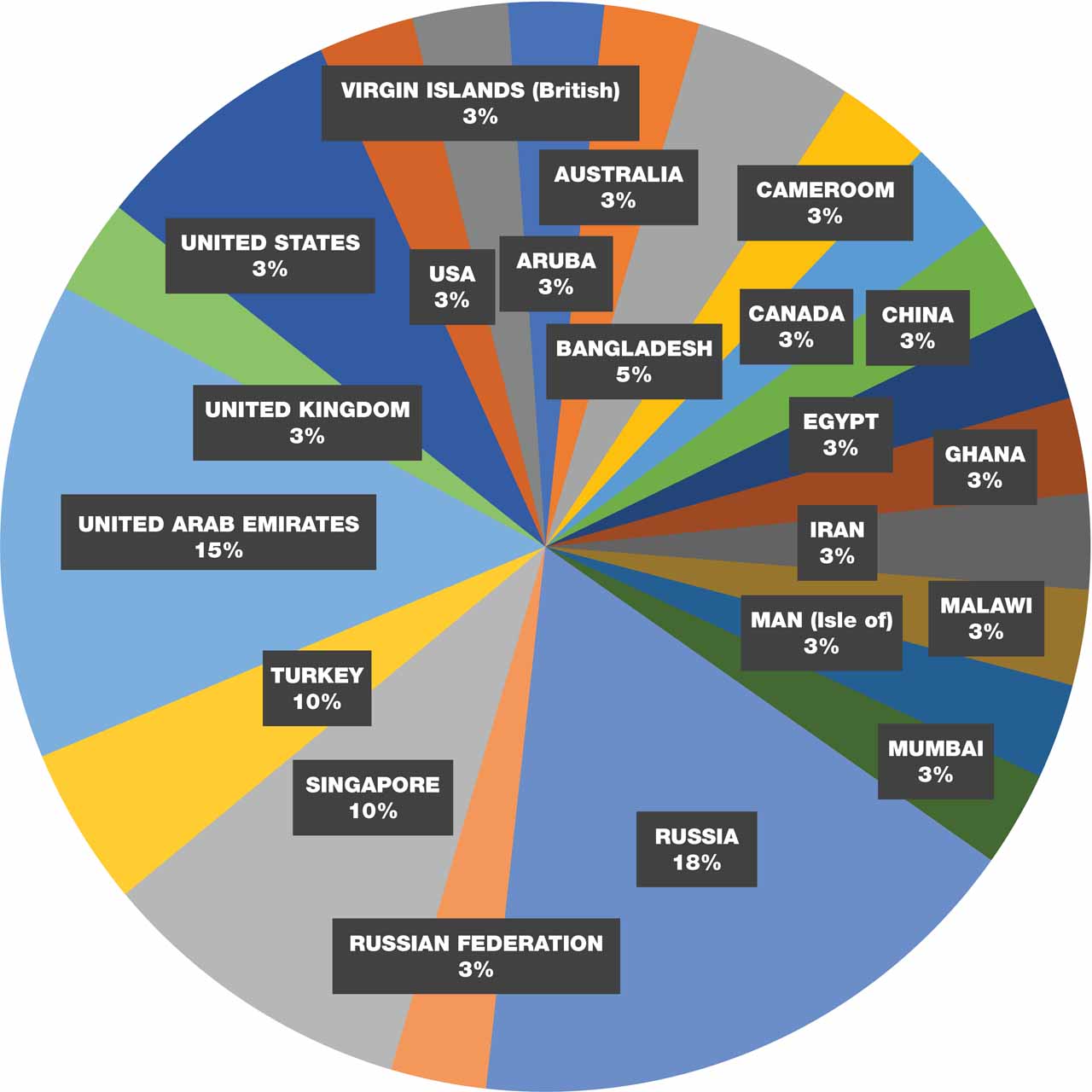

GSSE 2022 Visitor Footfalls

National: 25 states

International: 22 countries

Get more of Elevator World. Sign up for our free e-newsletter.