In this Technology article, your author shares insights on emerging trends in India’s elevator industry.

images courtesy of Inovance

The vertical-transportation (VT) industry is seeing significant technological changes in many areas, including commissioning, control, motors, maintenance and remote access. These exciting innovations across the sector provide a range of opportunities and challenges to elevator OEMs, as well as significant benefits to end users.

The Internet of Things (IoT) is becoming increasingly popular throughout the manufacturing industry and is now making its mark on the VT segment. When it comes to elevator technology, IoT solutions can be used to create smart elevators, that deliver a host of new capabilities, including remote, real-time elevator status monitoring and control, remote diagnosis and commissioning support and important predictive-maintenance data collection.

In addition, the increasing use of permanent magnet synchronous machines (PMSM) and the move toward gearless elevators delivers a range of benefits for VT, including higher power density and torque in a lighter, more compact package. PMSM gearless traction machines use permanent magnets to generate a magnetic field for the motor and deliver greater efficiency, controllability and a smoother ride.

IoT Creates Smart Elevators

Smart technology is revolutionizing the VT market by providing real-time information and remote access to elevators. OEMs looking to stay ahead of the curve should ensure they have explored the potential offered by IoT, with more than 64 billion IoT devices predicted to be installed worldwide by 2026[1] IoT refers to a network of connected physical devices that collect and exchange data, which can be shared in order to automate and optimize processes such as manufacturing and transportation.

IoT technology is being developed for the elevator industry and its end users, making VT smarter, more responsive, less complex and more efficient. This includes remote monitoring, testing and control in real-time, up-to-the-minute status reports, text/email alerts and self-learning capabilities.

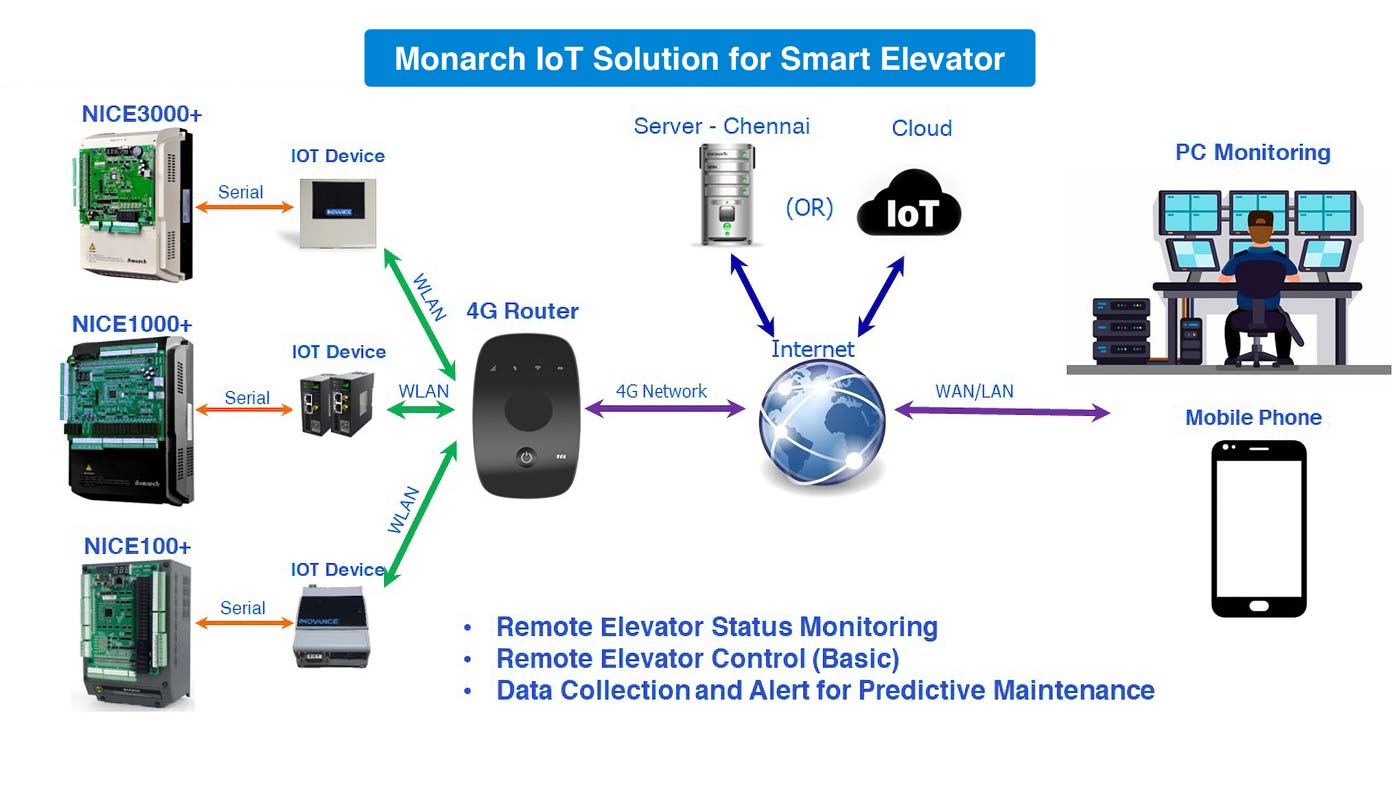

Inovance has its own IoT device that delivers connectivity between the 4G router and the rest of the world, providing remote monitoring via a smartphone or PC with internet servers based in India or in the cloud. Inovance has been working in smart elevator technology R&D for several years, and our Monarch smart elevator IoT solution includes all key features required by customers for elevators of the future.

What Can Smart Elevators Do?

Varying levels of control and complexity can be accessed via smart technology, ranging from remote monitoring for proper functioning and alerts delivered on any abnormal conditions, to remote assistance for commissioning and diagnosis and operation data collection for predictive maintenance to advise of the need for action before a breakdown occurs.

From the very beginning of an elevator’s active lifecycle, IoT can help to improve control, monitoring and service. This can help with remote elevator diagnosis for sophisticated issues where expert intervention is needed to restore the unit to normal. As the IoT details all data remotely, including parameter validation, elevator operational and fault code records and all I/O status monitoring, this information makes remote fault diagnosis easier and faster. With an IoT-connected smart elevator, a skilled expert can also assist a job site technician remotely for safe and quick commissioning.

Smart technology is revolutionizing the VT market by providing real-time information and remote access to elevators.

During operation, smart solutions enable trapped passenger alerts to be sent based on car panic/alarm buttons and load status. If an elevator is stopped between floors, floor call control and emergency communication systems can be used to call the elevator over the internet.

Other benefits IoT technology can deliver to optimize performance and enhance user experience for VT include enhanced energy savings (using intelligent algorithms and sensors), advanced security features such as biometric scanners and access control systems that provide increased capacity by reducing wait times and tackling bottlenecks. User experience can be enhanced through features such as virtual assistants or touchscreen interfaces, and wait times cut by considering factors such as time of day and building occupancy to optimize operations.

Predictive Maintenance Can Save Costs, Time and Labor

IoT can also deliver remote, basic elevator control for error reset to avoid unwanted callbacks and advanced predictive maintenance, with functional and error data and component operation counts collected and stored in a server to alert OEMs when maintenance is needed. Predictive maintenance solutions can monitor data relating to an array of different functions, including the operation count of doors, brakes, cars and counterweights, variable frequency drive run duration for the cooling fan, capacitor, motor temperature and controller warning errors, etc.

Many existing maintenance practices are labor intensive and time consuming, considerably disrupting business operations. IoT technologies work with sensors to make elevators more efficient, responsive and able to predict the likelihood of breakdowns before they occur, significantly reducing downtime and disruption to business operations, as well as reducing time spent on false callouts. OEMs can monitor the overall health of the elevator remotely and schedule maintenance proactively, with convenient access to real-time data from sensors.

The elevator industry in India is undergoing significant change, with the latest innovations marking an exciting time for companies involved in VT.

PMSM Motors: Faster, Smaller, Smoother

Another key trend that is emerging in the VT industry is the use of PMSM. PMSM traction machines are starting to play a central role in elevators — one that will only become more important over time — as they are smaller and more compact than traditional geared AC induction motors and deliver a wide range of benefits for OEMs and end users.

PMSM motors are now being used to create gearless elevators and provide high levels of efficiency, better controllability, smoother operation and increased reliability. The compact and lighter design of PMSM gearless traction machines paved the way for extensive use of machine-room-less (MRL) elevators in recent times, as it allows the owner to utilize the maximum allowable height of the building and reduces cost. The high torque and high power density they deliver means they can provide more power in a smaller frame size and, as the technology develops, costs are coming down.

Indian elevator OEMs are increasingly switching to PMSM gearless elevator technology, which offers smooth ride comfort, low audible electromagnetically induced noise and optimized direct-to-floor technology. Further, PMSM gearless machines produce higher power during regenerative direction running of the elevators compared to an induction geared machine, which can be converted into reusable energy with the help of the Monarch active front-end unit.

PMSM Gearless Traction Machines Without Gear Oil Are Better for Environmental Conservation

Our Monarch NICE integrated elevator controller range is precisely designed for PMSM gearless traction machines and integrates the elevator drive and controller into a single product. Having a complete solution such as NICE, which comes with pre-adjusted parameters suited to PMSM machines, means easy configuration. The safe, reliable and durable NICE range also supports different variants of encoder, meets EN 81 standards and will meet BIS 17900, with products being used by most of the elevator OEMs in India.

Looking to the Future of India’s Elevator Industry

The elevator industry in India is undergoing significant change, with the latest innovations marking an exciting time for companies involved in VT. This is a transformative period and OEMs need to be aware of the key trends affecting the market, as well as the challenges and many benefits they can offer to manufacturers and their end users. As technology continues to advance, new capabilities and features will emerge that enhance the performance of elevator controls and systems to improve user experience and make them even safer, smarter and more efficient.

Reference

[1] Phaneuf, A. (2020) “Top IoT Business opportunities, benefits, and uses in 2020,” Business Insider.

Get more of Elevator World. Sign up for our free e-newsletter.