Lift Automation Module for AGVs, Robots

Mar 6, 2023

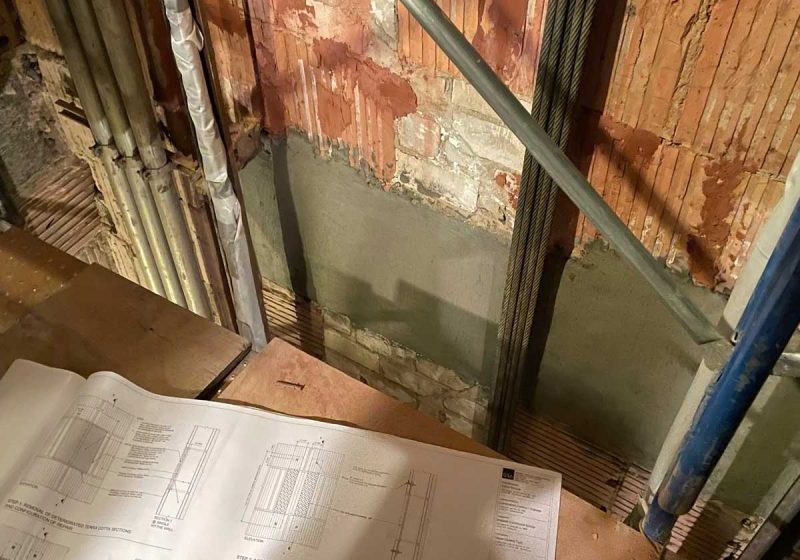

Heavy-load, multistory solution from Germany’s Lödige Industries is compatible with freight and goods lifts.

submitted by Lödige Industries

As available space for storage and distribution is scarce and, therefore, expensive, the trend toward multistory buildings is increasing. A new automation module from Lödige Industries allows both automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) to interact with different lift systems to move up to 20 mT of total weight vertically. Goods and freight lifts are intelligently networked with autonomous transport vehicles, enabling automated material transport across multiple floors. The automation module is compatible with both the Olympus freight lift and the Sherpa (ELEVATOR WORLD, July 2020 and July 2018) and Escorta goods lifts. There are various options for communication between the lift and the fleet management system. For example, parametric interfaces are offered for the Olympus goods lift, which reduces the need for cables and communicates directly with the fleet management system. In the future, this variant will also be available for the Sherpa and Escorta models. The new system is already being used in industrial production, for example in the automotive industry. Lödige Industries Chief Product Officer Tobias Wennekamp said:

“Through the intelligent integration of goods lifts, the range and, thus, the cost advantage of AGVs can be extended quickly and easily, even in existing buildings and confined spaces. Especially in combination with our Olympus goods lift, completely new possibilities arise for our customers in the heavy load range of up to 20 mT or more.”

Wennekamp, a mechanical engineer responsible for new technologies at the Paderborn, Germany-based provider of logistics systems and lift solutions, said AGVs and AMRs are important tools in optimizing intralogistics processes. The trend toward multistory production and warehousing, established in China and on the rise in Europe, further promise to drive demand for this technology, as well as an “automatic integration solution for goods and goods lifts” such as that offered by Lodige Industries.

Especially in combination with our Olympus goods lift, completely new possibilities arise for our customers in the heavy load range of up to 20 mT or more.

— Lödige Industries Chief Product Officer Tobias Wennekamp

Get more of Elevator World. Sign up for our free e-newsletter.