Membrane Potentiometers Simplify Position Sensing

Mar 1, 2011

Discusses how membrane potentiometers have changed the way engineers think about sensing and how they improve upon mechanical potentiometers.

by Guido Woska

Membrane potentiometers have changed the way engineers think about sensing. With some only 0.5 mm (0.05 cm) thick, ultra-flat membrane potentiometers feature comparable product characteristics to conventional potentiometers, but are liberal with design freedom at significantly lower costs.

Today’s membrane potentiometers can be used in the same applications as conventional potentiometers, and can also fit into space-constrained areas. The function can follow the form, a feature not often seen with mechanical potentiometers.

Because most producers of membrane potentiometers offer customized products with only small tooling efforts, the costs are competitive, even for small prototype quantities. Three additional advantages are found in the basic construction of the membrane potentiometer: the ability to

be fully sealed; the possibility for a hollow shaft design; and numerous wiper options, including operation by hand.

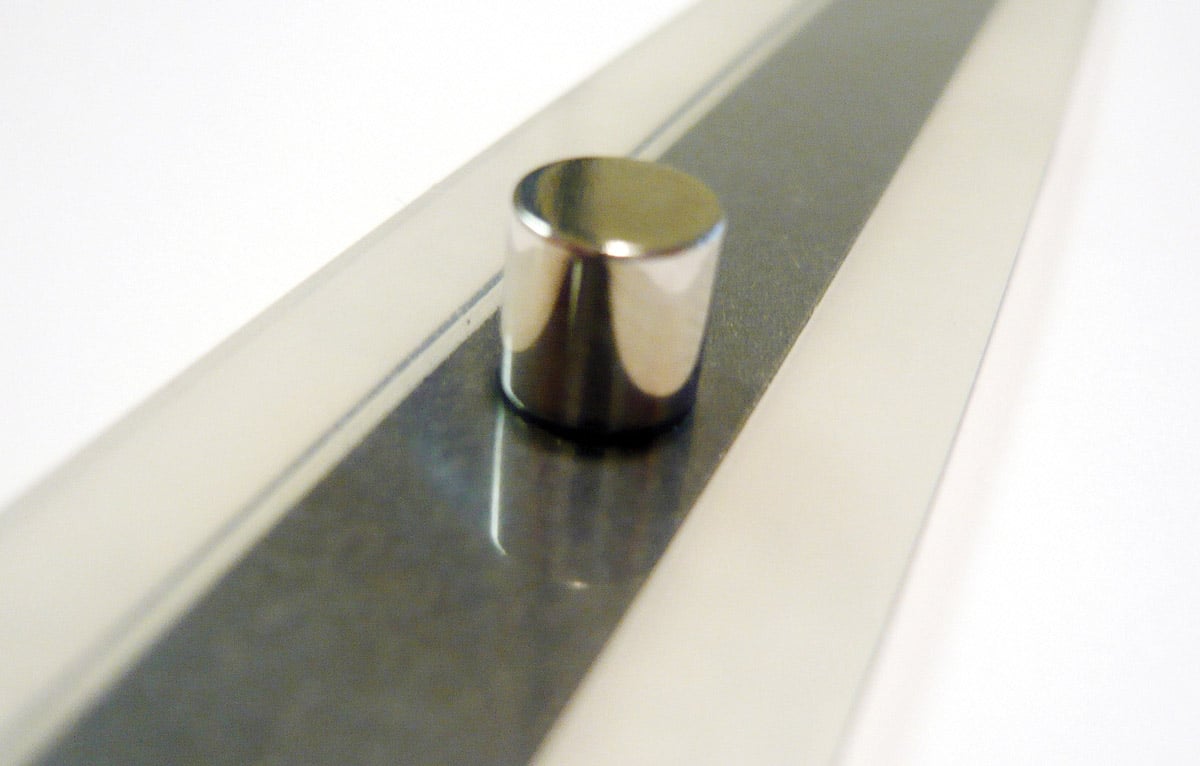

Most membrane potentiometer products can be sealed at up to an IP65 (NEMA4x) rating and higher. Conventional potentiometers require a difficult assembly of the wiper, particularly in a “hollow shaft” assembly, which is more reliable and cost efficient. Because of the simple nature of many membrane potentiometers, such technical adjustments are not required. The wiper for the membrane potentiometer can be as simple as a small plastic knob sliding across the surface and it requires no external electrical contact. Most membrane potentiometers can also be operated by sliding a finger over its surface and some even offer contactless magnetic versions.

Design Characteristics

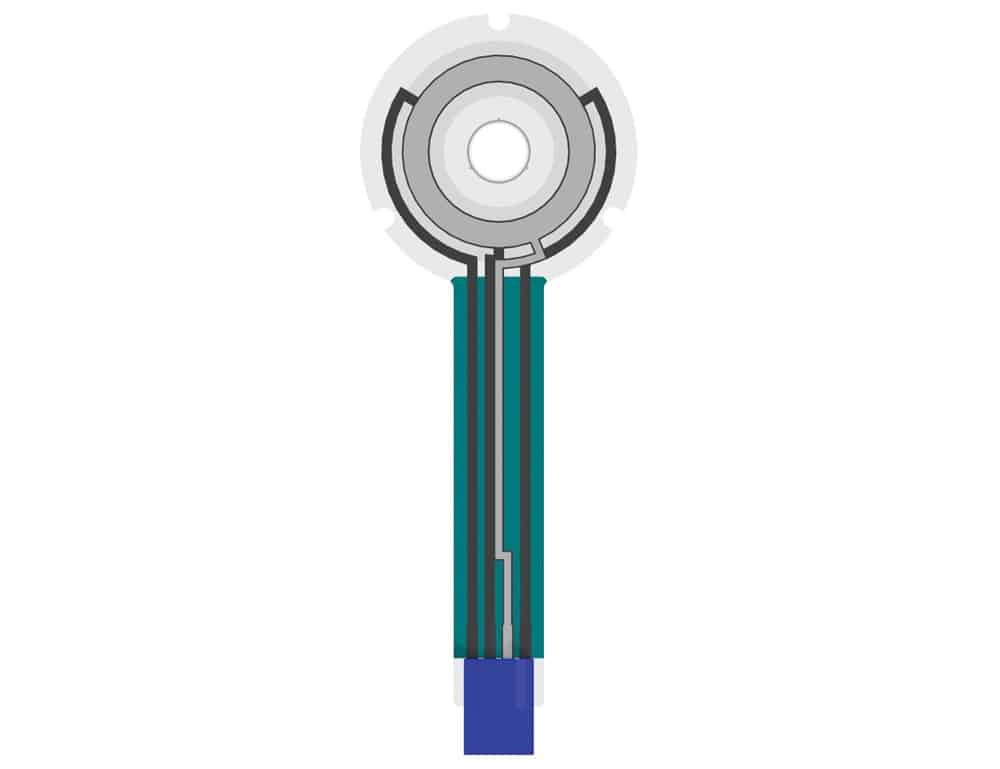

In general, a membrane potentiometer is a voltage divider – constructed as an open circuit that only gives output when the wiper connects the top and bottom circuits by applying pressure to the membrane surface. The spacing between the top and bottom circuit is constructed mainly of a sealant adhesive, which allows the potentiometer to be sealed against external environmental factors, such as moisture or dust. This spacing adhesive requires a minimum width of 2 to 3 mm (0.2 to 0.3 cm) on all sides of the membrane potentiometer. The ideal width of the resistive active area should be between 3 and 6 mm (0.3 and 0.6 cm), but can also be extended to 10 mm (1 cm) or even 12 mm (1.2 cm). Linear elements can reach up to 760 mm (76 cm) in active length, while rotary elements with a center hole can measure from 20 mm (2 cm) diameter to approximately 450 mm (45 cm) diameter.

The life cycle and operating temperature correspond to those of mechanical potentiometers’ more than 20 million movements, depending on the design even up to 100 million operations are possible. The operating temperature can range from -40°C to +85°C (140°F to 185°F) and there are even systems in development that can withstand temperatures up to 125°C (257°F).

Due to the design of membrane potentiometers, temperature compensation is not necessary if being operated in a voltage divider mode, and electromagnetic interference will not affect the system.

The standard actuation is a wiper or slider but some types require a defined magnet instead of a wiper. For hand tipping actuation, a SET-function (value does not change) in Z-direction is available as an option.

Installation Process and Wiper Design

Due to the flat design of membrane potentiometers, they can be brought close to the motion area of the device which it is measuring, and does not requires much installation space. They are adhered on a substrate by simply removing the protective paper and applying it to the surface, other options are snap-in mounting or using screws. The wiper can also be easily integrated into the application.

With small quantities, an off-the-shelf wiper might be the easiest choice, while with higher quantities or space limitations, a custom designed wiper might make more sense. One application might require a spring-loaded screw; others will require a spring-plate attached to a POM/Delrin plastic; each application is particular to the needs of installation space, cost and accuracy.

If lifecycle requirements are very high, a magnetic wiper is recommended for contactless connection. In general, a spherical wiper can be recommended. The typical wiper covers about 10 to 50% of the active width. Materials such as steel, brass, hard plastics (e.g. Delron, Delrin) are typical, but depend on the type of membrane potentiometers. Engineers should always seek advice from the manufacturers regarding the right choice of material.

Surface Pressure

Different surface pressures are defined depending on the application, but in general 1 Newton (N) up to 6 Newtons (N) is the range that is recommended for most applications, depending on whether the membrane potentiometer is configured in a standard foil layout or in a hybrid version with additional metal bonds to strengthen the structure. Standard off-the-shelf wipers are usually divided in a 1 to 3 N and a 3 to 6 N range.

Electrical Characteristics

The electrical characteristics will vary somewhat with the design, but are generally standard, with similar output to a conventional potentiometer, e.g. as voltage divider.

In comparison to the conventional precision potentiometer, the most significant difference is the method of achieving linearity. While the conventional potentiometer might use laser-trimming to achieve linearity, membrane potentiometers, which are based on PET-Material (a thin film), rely on production improvements to improve linearity. Hence, the typical linearity offered is 2% for standard linear potentiometers, although FR4-based membrane potentiometers can reach as little as 0.5% as an option.

But, more important than linearity, is the repeatability and hysteresis. The accuracy of membrane potentiometers can be as good as 0.01 mm (0.001 cm) over a length of 500 mm (50 cm), but most standard membrane potentiometers range anywhere from 0.05 mm (0.005 cm) to 0.1 mm (0.1 cm). The main impact on all of the electrical outputs is found in the mechanical motion and stability of the wiper. As a benchmark, energy dissipation of up to 1 W and a dielectric strength of 500V is standard, with isolation strength of 100VDC also possible.

Applications

A typical application, due to the small height of membrane potentiometers, is the linear measuring of actuators. Control valves are another benefited application, in which the standard currently requires gears and a turning sensor to measure position. The structure required to install and use a membrane potentiometer is much more simple and form-friendly than the large and difficult mounting of certain conventional potentiometers.

An improved design, creating linear output signals right next to the motion device, can sometimes increase accuracy over a conventional rotary potentiometer, which is connected by gears far from the actual motion which is being measured. Hoffman + Krippner’s SENSOFOIL® can reduce these costs significantly.

In many applications, both rotary and linear membrane potentiometers can be used in the same device, (e.g. a seat

level adjustment requires linear motion), while inclining the seatback angle requires rotary motion. Similar applications are found in automotive interiors, where sliding doors, sun roofs, seats applications, etc. require small installation spaces and low weight.

Another simple solution to space problems is using the printed-circuit board (PCB), which already exists in many applications, as a base for the membrane potentiometer. The PCB can be fully populated, and afterwards, the membrane potentiometer can be adhered to the board and the connectors inserted directly into the PCB. Additionally, few manufacturers can even print a conductive ink directly on FR4 and combine this with PCBs and components, as they are able to directly assemble the components onto the PCB.

Other applications, which use a membrane potentiometer mainly for cost saving reasons, are string-pots/wire sensors and magnetic tape. Additionally, membrane potentiometers can be fully integrated into a keypad for hand-control. Seamless integration makes the keypad highly innovative and useful for position tracking. The integrated potentiometer can avoid installation holes, as needed by a standard potentiometer and can create a completely sealed and washable front panel surface.

In relevance to elevator and escalator technology, membrane potentiometers can be integrated into a variety of applications. They can be used in elevator door systems to prevent doors from closing on passengers. Additionally, they are appropriate for position sensing of the actual elevator car relative to the position of the floors. The sensors do not require contact between the moving cabin and any static device, as they can measure current position and any change in position contactless via the option of magnetic operations. Membrane potentiometers can also be useful inside the elevator car, as their functionality relies on pressure. They can be integrated into touch panels and work as input devices, both for direct input (i.e. pressing of a button) or continuous input (i.e. slider functionalities).

Conclusion

Because of its ultra-flat design and flexible usage, combined with low costs, the membrane potentiometer has opened up sensing possibilities which were not possible before. With new and innovative materials like magnetic operations or hybrid membrane potentiometers, designers and engineers can use these potentiometers in different applications. Complex sensor constructions can be reduced, simplified and integrated less expensively with modern membrane potentiometers.

Get more of Elevator World. Sign up for our free e-newsletter.