Improvements in space savings, residential installation, monitoring and metering join a new steel-belt-cable MRL system.

MRL Elevator for Low- to Mid-Rise Buildings thyssenkrupp has launched evolution

200, a cost-effective machine-room-less (MRL) elevator for buildings up to 350 ft. tall, in the U.S. and Canada markets. evolution 200 has up to 5000 lb. capacity and 600 fpm speed. This, the company states, means “building owners no longer have to sacrifice size for speed.” The system uses rubber-encased, steel-belt cables rather than traditional steel-wire ropes, which decreases the elevator’s footprint due to smaller sheave sizes that correspond to smaller pits and overhead space. The cables also last longer than steel cables.

Reduced hoistway size opens up more leasable or usable area for building owners. The controller fits into an 8-in. door jamb and is fully digital, saving space and reducing noise. A regenerative drive, which captures unused energy and feeds it back into the power grid, is standard on evolution 200. The unit switches to standby mode when not in use. In addition, automatic fan and light shutoff can reduce cab energy use by up to 90%. Health product declarations and Cradle-to-Cradle Material Health certifications help buildings meet Leadership in Energy and Environmental Design certifications. evolution 200 includes standard “emergency auto rescue,” which enables safe transport of passengers during power outages. All units include the predictive-maintenance tool MAX to maximize uptime.

thyssenkruppelevator.com/elevator- products/evolution200

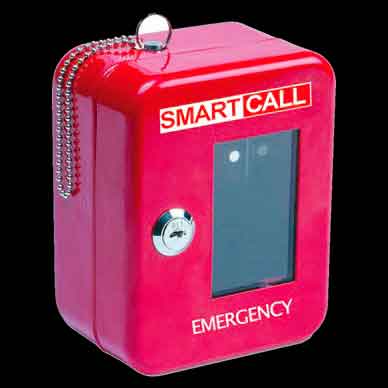

Wireless Car Monitoring, Calling

Smart Call Systems LLC’s Wireless Call System can remotely monitor the location of hoist cars in real time with a mobile app. It is connected to hardware in the hoist cars and includes sensors that detect hoist-car location and time spent on each floor, plus cameras that offer video footage of the interior of the hoist car, all of which can be viewed from the app. There are waterproof displays in each car that show call requests from floors, and they are connected to a base station on the ground floor that transmits over-the-air updates and reports via a cellular provider.

Smart Call’s Wireless Emergency System for construction sites is comprised of emergency boxes on every floor with a button to press in the event of a crisis. The button signals alarms on the displays in each hoist car and in the construction-site offices. When the alarm sounds, the display signals where the emergency is located. A text-message alert, which includes an interactive map and emergency phone numbers, is sent via a cellular provider to a predetermined list of emergency responders.

Specialty contractor Universal Builders Supply, Inc. (UBS) has implemented wireless technology from Smart Call in its hoist cars. UBS said it is now in lifts at construction sites throughout Manhattan, New York. “We worked with Smart Call directly to trial these new systems, and, having tested them, found that this technology [creates] a seamless hoisting experience, which we are excited to share with the industry,” UBS President Chris Evans commented.

Multifunction Electrical Meter

ATC Diversified Electronics’ VCFP96M Multifunction Meter monitors power quality and demand via six critical parameters of electrical systems. Its complete single- and three-phase digital metering system is suitable for low-, medium-, and high-voltage control panels, generator sets, load banks, and building and power management systems. The monitoring function can help determine where electrical inefficiencies exist and eliminate costly “phantom power” usage. Its display has four rows, LCD backlight and a representation of current via a bar graph.

The VCFP96M can be used on single-phase, three-phase three-wire, as well as three-phase four-wire balanced or unbalanced systems. The six front control keys are used for scrolling up or down through the parameters of voltage; current; power factor; power (active, reactive and apparent); energy; and frequency. The meter is permanently installed into the panel box and can use both pulse output and the RS485 Modbus RTU communication protocol.

Hydraulic Residential Elevator Hides Under Stairs

Inventor Todd Edmunds and Country Home Elevator plan to release The Stairwell Elevator this year. Using the stairway as a “shaft,” the stairs pivot so that the hydraulic lift has room to operate. Edmunds created the device for his quadriplegic brother. It uses a patented design to move the stairs. Then, the elevator is raised and lowered in a space that, in many homes, goes unused. Edmunds explained:

“Since my wife wisely would not let me cut a hole for an elevator in the living room floor, I realized that the basement stairwell seemed like it could work instead. Finding the staircase held in place by just a few nails, I cut through those nails and bolted on some gate hinges at the bottom to allow the stairs to easily pivot out of the way. Using part of an old personnel lift found in a salvage yard and various hydraulic and electric components from eBay, I then built a telescoping platform lift that could fit underneath the staircase.”

Intended for residences and care facilities such as senior and home-living centers, its benefits are:

- No shaft construction required

- Space conservation

- Can be installed in almost any home with stairs

- Preserves aesthetics

- No dedicated shaft, pit or overhead clearance required

- Constant pressure-controlled operation

Get more of Elevator World. Sign up for our free e-newsletter.