New Rise Building

Jun 4, 2022

Fujitec supplies VT for Omkar Alta Monte.

by Sreekumar Nambiar

Mumbai is home to many high-rise buildings. The majority of high-rise buildings are residential, and one of the best among them is Omkar Alta Monte. This is a tower with an amalgamation of all the good things that a harmonious lifestyle should aspire to: inspired architecture, progressive lifestyle, well-designed living spaces, intelligent landscaping, plenty of green spaces, smart amenities and resourceful connectivity.

Keeping their high standards, Omkar Alta Monte also required a world-class elevator system that would meet the international standards of quality and energy conservation. For this purpose, the group evaluated a number of elevator system providers in India. After an in-depth process, Fujitec India emerged as Omkar Alta Monte’s official partner for the elevators.

A total of 15 “Made-in-India” elevators were provided for the project. The models are Zexia IN, with a capacity of 17 persons and 20 persons, speed of 4 m/s and special etched pattern finishes along with a mirror finish. In Tower D, the team behind the project have supplied elevators, which open directly into the passenger’s house.

A Single Solution for the Building System

Alta Monte decided to partner with Fujitec India on a variety of building systems for this residential project. Bundling systems allows building owners to have one source for all support, repair and maintenance needs, while reducing energy costs as Fujitec India building systems use the minimal energy required and lengthen equipment life, providing reliability for a building’s mechanical, vertical and electrical systems.

It has a nighttime self-checking operation, which checks during the stage when the elevator doesn’t receive any car and hall calls. The system will move the elevator and check the mechanical brake conditions automatically. This further improves safety and reliability. Quality and reliability testing prior to handover reduces the need for maintenance calls.

With second-to-none quality, Fujitec elevators are gearless, delivering a world-class ride, maximum life cycle and exceptional reliability with a speed of 4 m/s.

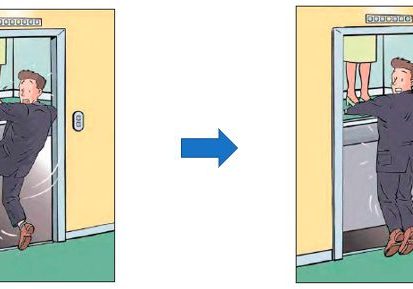

The integration of a destination control system (DCS) ensures authorized users/passengers are able to gain quick and efficient entry to an elevator. This results in shorter transit times and fewer intermediate stops, which will save time, reduce energy consumption and improve buildings efficiency.

Cab interiors feature an etched pattern, a design that suits the taste of the passengers and integrates well with the overall design of the building. The unique car operating panel exhibits a 10 digit-keypad consisting of a symmetric matrix of 12 configurable touch-sensitive buttons arranged in three columns and four lines. This exemplifies the advantage of using standard components already present in the market.

Fujitec India has close to 18 years of experience in the research and manufacturing of world-class elevators, escalators and auto walks. Fujitec India Pvt. Ltd. is a fully owned subsidiary of Fujitec Co. Ltd. Japan.

To keep pace of growing demand, Fujitec India has set up a manufacturing facility in Chennai-Mahindra World Center, a total area of 39,100 m2. Fujitec realizes the importance of an elevator system in determining the degree of serviceability of a highrise.

The Fujitec Elevator Make-in-India journey began with a manufacturing facility in India in 2010. Since then, the company has been expanding production and our portfolio for the Indian market of its high-quality, reliable products.

Team members were given the opportunity to serve the country by supplying elevators at the Omkar Alta Monte project. As standard features, they are equipped with specific functions required in India, such as automatic landing devices that can operate in the case of a power failure and other safety features.

The use of locally produced products ensures reduction of CO2 emissions during transportation, as well. Thus, designers ensure uncompromising safety and environmental sustainability simultaneously with our Make-in-India products.

Key Highlights

- Capacity: 1360 kgs; 20 passengers

- Travel height: Maximum 202 m, 59 floors

- Speed: 4 m/s

Get more of Elevator World. Sign up for our free e-newsletter.