Precision in Motion

Aug 1, 2025

Sagle, Idaho-based EPC’s Encoder cross-reference solution lifts a major elevator manufacturer’s supply chain.

submitted by Encoder Products Co.

Encoder Products Co. (EPC) was founded in 1969 by a Northern Idaho native, Bill Watt. While the component manufacturer sells its products globally today, the company began with deep roots in the Northwest producing a line of custom encoders — the original Cube series — from a small, home-based shop. EPC has manufactured high-quality encoders at its Northern Idaho facility since the company’s founding.

As the largest privately held encoder manufacturer in North America, EPC produces the most complete line of incremental and absolute rotary encoders. Having invented the original Cube encoder, EPC prides itself on its focus on quick, live expert responses to customers’ requests and delivering technologically advanced products. The company also repairs and evaluates customers’ products sent to its Idaho facility. A strong work ethic and customer-centric mindset are cultural aspects of the Northern Idaho-based company and workforce.

When a leading elevator manufacturer faced a critical supply chain issue, EPC stepped in with an innovative cross-reference and rapid fulfillment solution that kept production on track. This solution lifted long-term confidence in EPC’s engineering and support capabilities.

A Case Study: Replacing a Legacy Encoder

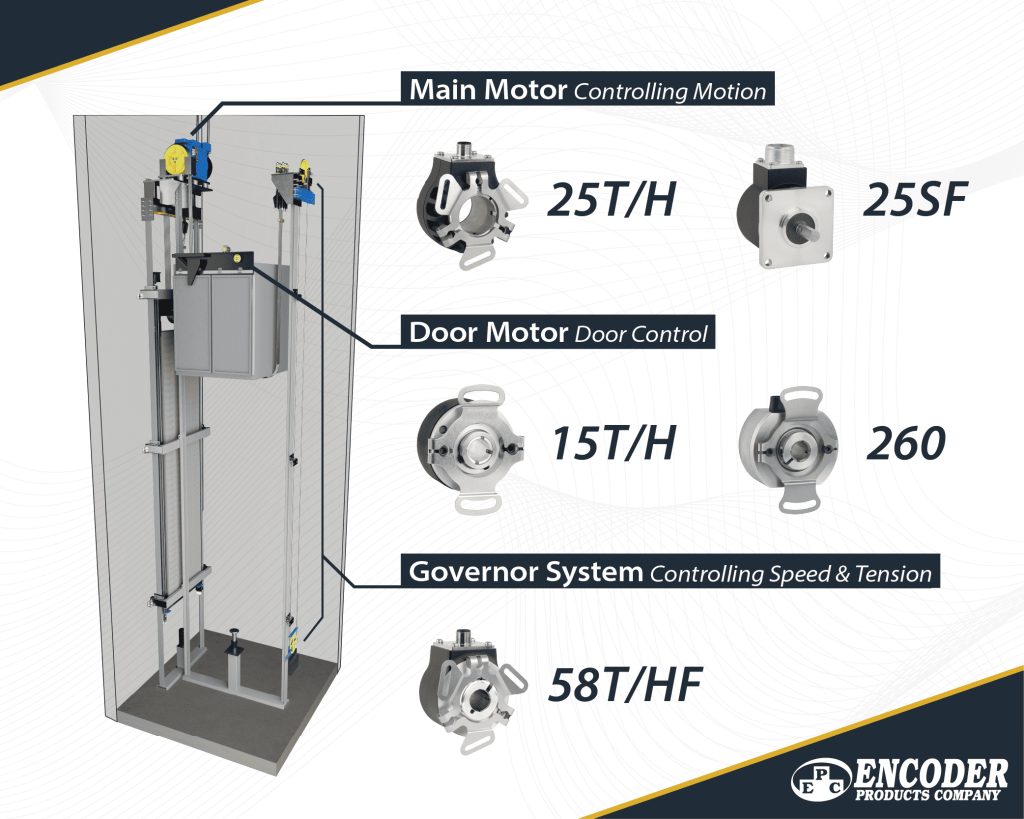

EPC worked with the global elevator manufacturer to solve an urgent challenge: replacing obsolete encoders used in a key assembly without disrupting the production schedule.

With decades-long experience in reliable motion feedback systems, EPC’s team leveraged its engineering expertise and flexible manufacturing capabilities to support, test and deliver an effective cross-reference encoder.

The elevator manufacturer relied on an encoder model that was no longer being produced by the original vendor. Facing limited availability and rising costs from aftermarket suppliers, the company needed an immediate alternative to avoid delays on production lines and deliveries to customers.

The original encoder was integrated into an elevator door assembly, where it played a vital role in position feedback for the system’s motor controller.Without a suitable replacement, the manufacturer risked costly downtime and missed project deadlines.

This supply chain challenge emerged during an active production period at a North American facility. The customer’s procurement and engineering teams were seeking a cross-reference solution that would require no re-engineering of the mechanical or electrical interfaces — a drop-in replacement with equivalent or better performance.

Delivering a Compatible, Tested Solution

EPC began by reviewing the mechanical dimensions, electrical specifications and performance criteria of the legacy encoder. From there, their engineers recommended a Model 15T, a compact and rugged thru-bore encoder known for its flexibility and precision. After confirming form, fit and function requirements, EPC provided a test batch for the elevator manufacturer’s engineering team.

The units were subjected to in-house validation testing, including:

♦ Mechanical fit and mounting

♦ Electrical signal compatibility

♦ Functional performance under real-world conditions

The Model 15T passed all evaluations, and the manufacturer approved it for use across multiple production lines.

Partnership, Flexibility and U.S.-Based Manufacturing

Several factors made EPC the right partner for this urgent project:

♦ Responsive Engineering Support – EPC’s technical team worked closely with the customer to identify the best-fit product and quickly resolve compatibility questions.

♦ Fast Turnaround Times – With vertically integrated U.S. manufacturing in Idaho, EPC could deliver production-ready encoders in days.

♦ Product Reliability – The Model 15T is known for dependable performance in industrial automation and Original Equipment Manufacturer applications — a perfect match for the demanding elevator industry.

♦ Ongoing Partnership – Following the successful implementation, the customer had the ability to expand its engagement with EPC for other encoder sourcing and cross-referencing needs. EPC continued to support the customer’s needs.

A Seamless Transition and a Strengthened Supply Chain

Thanks to EPC’s expertise and nimble manufacturing operation, the elevator manufacturer avoided costly disruptions and replaced a legacy component with a high-performance encoder.

Even more importantly, the success of this project demonstrated the value of working with an encoder supplier that offers:

♦ Custom engineering support

♦ Speed and flexibility in fulfillment

♦ U.S.-based design and manufacturing

♦ A robust cross-reference database

Get more of Elevator World. Sign up for our free e-newsletter.