Spider Leverages 70 Years of Experience

Aug 1, 2017

This Product Spotlight focuses on the Seattle-based company’s hoists, false car and work basket.

Spider® by Safway Group is investing in an expanded elevator product lineup. It has been bringing product innovation, productivity and safety to temporary powered suspended-access applications in the commercial construction, infrastructure, power generation, offshore and wind-energy industries for 70 years. Now, by leveraging its market presence in hoists, work platforms, rigging equipment and safety solutions, Spider is working toward becoming a global leader in premier access tools and accessories for elevator installations and modernizations.

Spider has been able to apply decades of suspended scaffold engineering expertise and code compliance to elevator applications. “Many of the same codes and principles that apply to working at height on exterior buildings and structures also apply to elevator work, so the expansion into the elevator segment was a natural fit for Spider,” explained David Beckett, Spider vice president and general manager. “We’re building on our core suspended-access expertise to develop a full range of elevator access solutions that meets the unique needs of global, regional and independent elevator installers.”

Listening to its customers and field-level users has been a critical driver in Spider’s product development. Elevator installers consistently ask for solutions that increase safety and productivity on the jobsite. In turn, Spider designed and manufactured a new generation of high-speed, Underwriters Laboratories (UL)-listed traction hoists. The SC1500-GHS and UpPro P1009 GHS are not only capable of traveling up to 70 fpm, but also offer increased lifting capacities at 1500 and 2200 lb., respectively. High-capacity hoists improve productivity on the jobsite by eliminating double reeving when lifting heavy car slings, and reducing trips up and down the elevator shaft when lifting door frames, for example. Spider continues to invest in new personnel-hoist solutions with increased lifting capacities to keep up with the evolving installation methods of its customers.

In addition to personnel hoists, Spider has leveraged its fully integrated engineering and manufacturing capabilities to expand its product offering to elevator installers, making it easy for them to obtain all their access equipment from one reliable source. False cars, rigging equipment and material lifting hoists round out the product lineup, along with accessories like belt cutters and custom tool kits.

History

Spider’s story began in 1947 in a garage in the suburbs of Seattle. Brothers Sid and Bud Fisher started tinkering with an external access solution for working at height. The Spider ST-17 work basket was developed, and Spider Staging Corp. was born. Starting with a pair of accidental inventors responding to a need for elevated access to industrial structures and high-rise commercial buildings, Spider transformed from a single-solution provider into a vertically integrated, multichannel platform with more than 250 employees and 25 locations throughout the Americas. Now, it rents and sells its products throughout the U.S. and Canada via an extensive branch network that continues to grow.

The company also actively participates in the development of elevator codes through the American Society of Mechanical Engineers, membership in industry organizations including the National Association of Elevator Contractors and European Elevator Association, and investment in ISO 9001:2015 and OSHA 18001:2007 certifications and UL listings. Notably, in 2016, all 25 of Spider’s operation centers were accident free.

As Spider celebrates its 70th year, its team reflects on key milestones, including the 2015 acquisition of German hoist manufacturer DualLift GmbH, which made Spider the largest traction-hoist manufacturer in the world. Spider was acquired by Safway Group, a leading provider of scaffolding, access and industrial services, in November 2016. In summer 2017, Safway merged with Brand Energy & Industrial Services to create an integrated global specialized-services organization focused on delivering more value to customers in the industrial, commercial and infrastructure end markets.

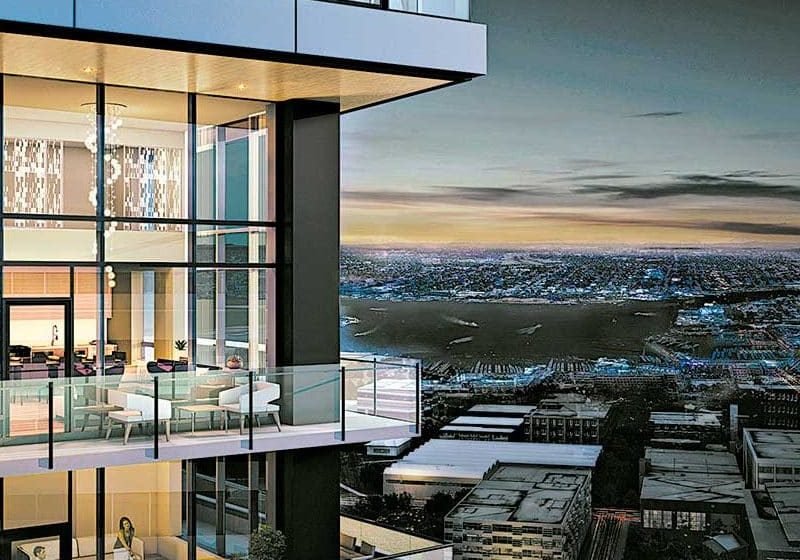

With landmark projects like Hudson Yards in New York City, Barnes-Jewish Hospital in St. Louis and 800-ft.-tall residential high rises in Chicago, to machine-room-less elevators on smaller-scale facilities, Spider serves elevator installers around the globe. Becket concluded:

“This is an exhilarating time of change and opportunity for Spider. With a corporate mindset of continuous innovation and improvement, a history of unprecedented market leadership and a dedicated team of experts, Spider’s future is bright. We will continue to strive each and every day to provide safe, quality solutions for the elevator industry and beyond.”

Get more of Elevator World. Sign up for our free e-newsletter.