An array of offerings from North America and Europe

Biodegradable Hydraulic Elevator Fluid

Elk Grove, Illinois-headquartered BIO BLEND® offers BioFlo Elevator, a readily degradable, high-lubricity elevator hydraulic fluid that boasts proprietary, non-toxic, anti-rust and anti-corrosion additives. Its special rust and oxidation additives and anti-foam agents help provide maximum demulsification of water and reduce air entrainment to provide higher circulation rates. The high-performance formula can reduce operating temperatures, friction and component wear in hydraulic elevator systems. BioFlo Elevator’s excellent thermal and oxidative stability ensures superior service life with minimal viscosity change over a broad range of operating temperatures. This elevator hydraulic fluid is available in ISO 40. It is classified as an Environmentally Acceptable Lubricant (EAL) per the U.S. Environmental Protection Agency’s (EPA) guidance document that defines EAL standards as required by the EPA’s 2013 U.S. Vessel General Permit.

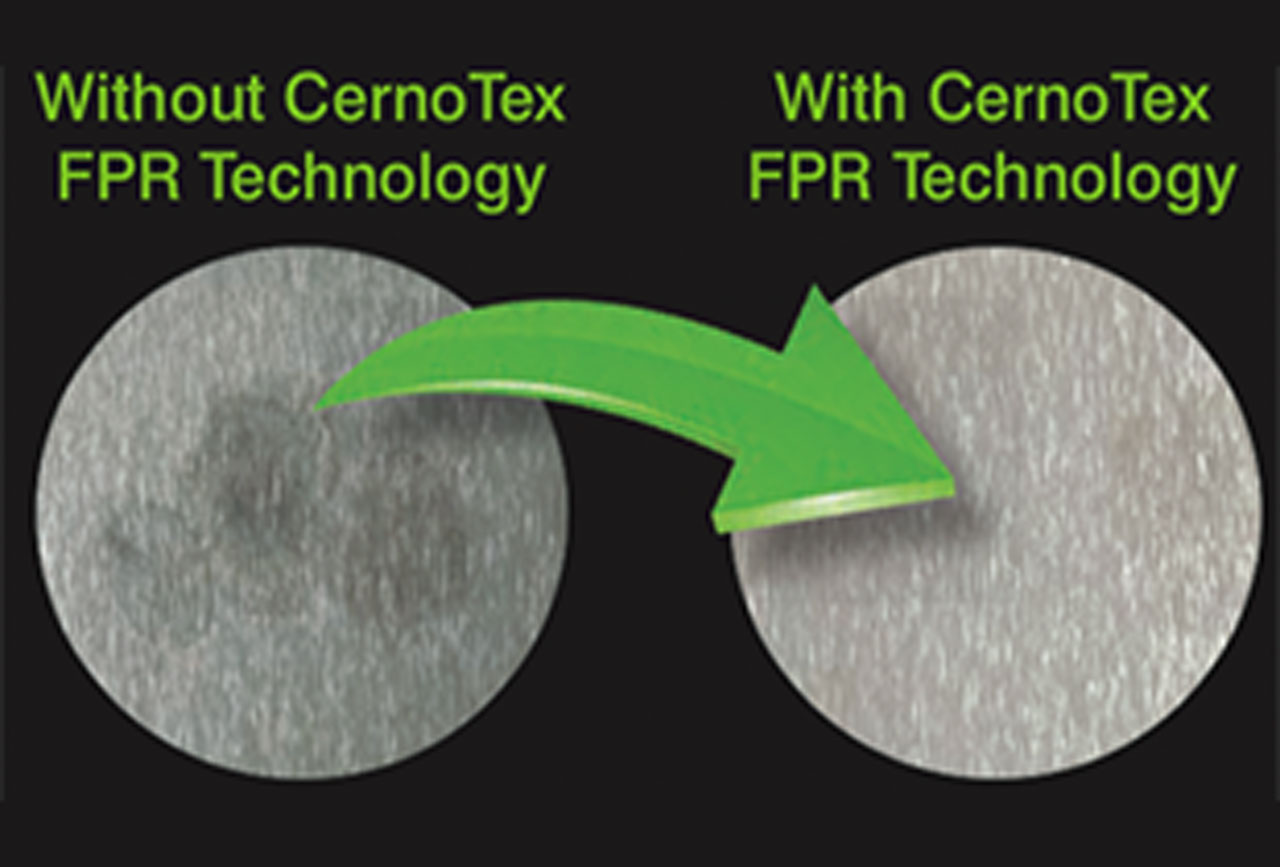

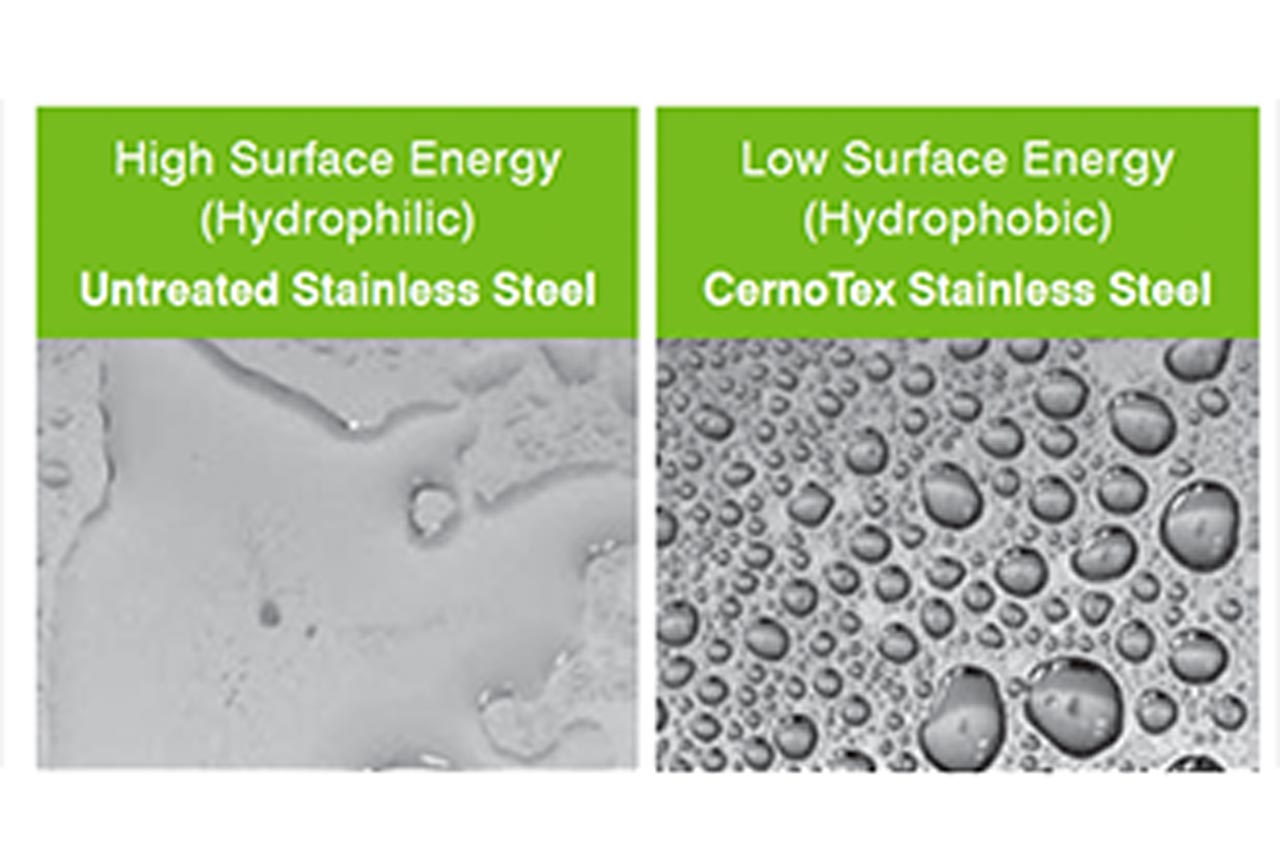

Fingerprint-Resistant Film

Rimex Metals (USA), based in Edison, New Jersey, announces a complimentary addition to its family of specialized metal finishing with the launch of the CernoTex™ Fingerprint Resistance Technology production line. CernoTex, a ceramic, fingerprint-resistant film, enhances the aesthetic quality of metal products by reducing the adhesion of fingerprints and markings on stainless steel sheets. The nanocoated film is also easy to clean. CernoTex is ideal for interior applications, especially high-touch areas, on a range of Rimex natural, colored surface and patterned stainless steel finishes. CernoTex has been successfully tested for cutting with fiber and CO2 lasers, as well as blanking, using punch and die techniques. The product’s protective, ceramic nanocoat is achieved through a chemical process known as the “Sol-Gel Process,” which is a method of utilizing wet chemistry to synthesize thin, dense, hard coating with glass- or ceramic-like properties. Additional benefits include:

- Significant reduction in fingerprints and grease

- Good fabrication characteristics

- Low surface energy (hydrophobic)

- Reduced maintenance costs due to easier cleaning

VT Asset Management Software

Lift AI is launching its new Asset Management Platform software, AMP, built specifically for vertical-transportation (VT) consultants and their property owner/manager clients and enabled by Lift AI’s industry-leading Internet of Things technology. Releasing in May to Lift AI launch partners and soon in general availability, AMP provides complete oversight of all elevator and escalator maintenance based on regularly scheduled calls with Lift AI’s consultant partners who work with VT maintenance providers to deliver on VT asset management objectives. The solution allows users to implement a proven, performance-based maintenance contract that delivers desired, measurable results, with ongoing monitoring through maintenance ticket and invoice data. Additional features are planned to be released later this year. Compliance management will record all regulatory-required inspections and certificates of compliance that result. It tracks violations to ensure quick resolution of any problems to minimize liability, cost and tenant disruptions. Callback management will track all VT equipment issue calls and problem resolutions, allowing users to identify and address recurring issues and improve overall performance. Finally, AMP software enables the review of all invoices for approval by VT consultant partners, recording relevant information digitally for effective cost management and decision-making.

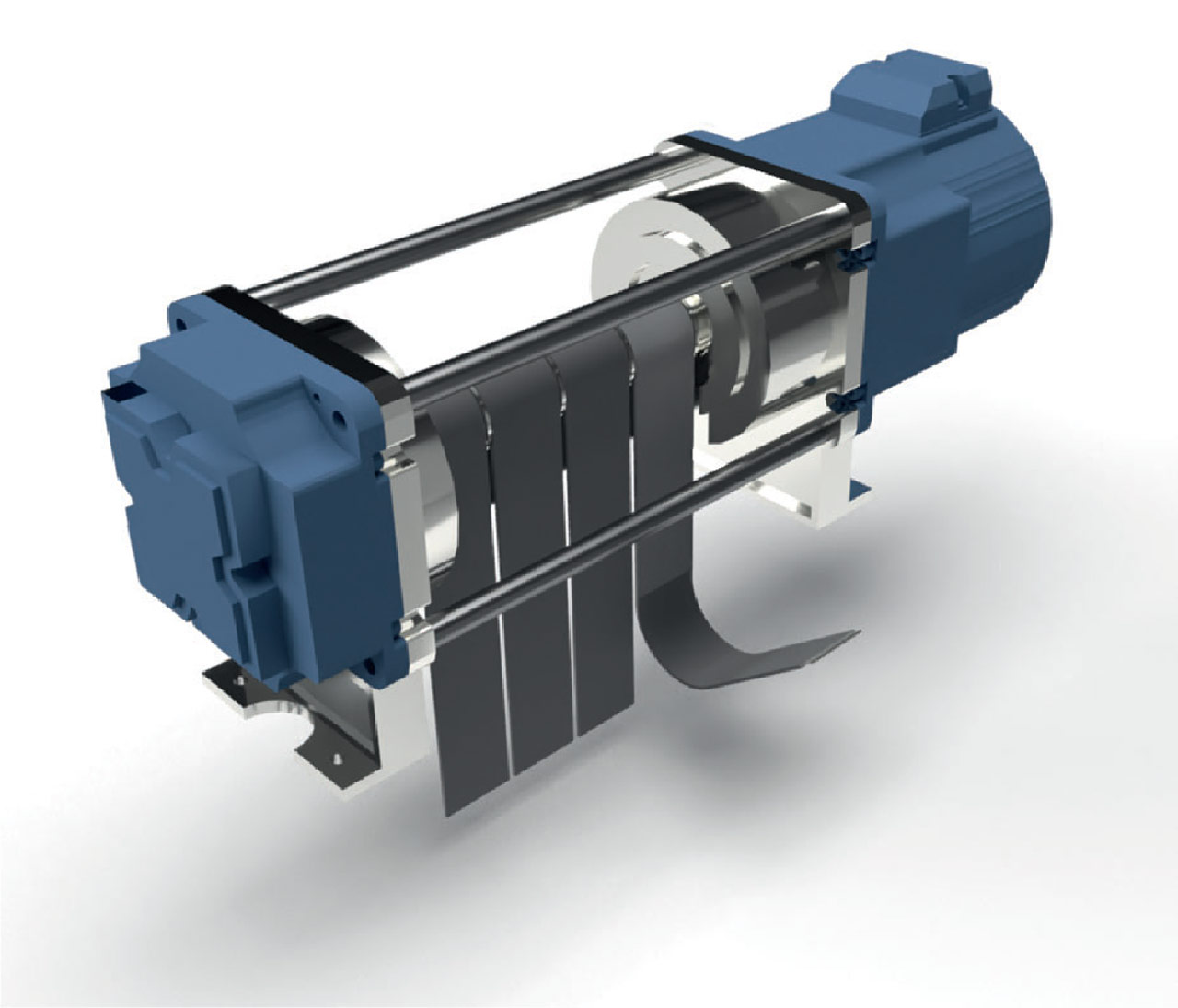

Lift Suspension Means

Val Brembilla, Italy-headquartered ElatechSrl offers the Elatech® F3 composite polyurethane lift suspension belt, which was recently certified by Liftinstituut. The flat belt is made of strong steel tension members that are covered by a robust and abrasion-resistant layer of black polyurethane. Advantages include:

- Reduced pulley diameter and encumbrance in the machine room

- No lubrication

- Low energy consumption and noise levels

- Abrasion resistance

- Long service life

When presenting the certificate to the Elatech team at interlift in Augsburg, Germany, in 2022, Liftinstituut observed:

“For over a century, steel ropes have been used as traction suspension means for elevators. Around the year 2000, the first alternatives appeared in the form of robust polyurethane belts that were significantly lighter than steel ropes, allowing them to run over smaller diameter pulleys, resulting in more compact, efficient drives and easier maintenance. Elatech, one of the leading manufacturers of polyurethane belts, has been supporting elevator manufacturers with high-quality traction suspension belts since 2004.”

Get more of Elevator World. Sign up for our free e-newsletter.