Door System Design Evolution

Jun 3, 2025

A consultant’s take on how and why the practice has developed as it has

As this issue’s focus is upon door systems, it is useful to consider how design has evolved to its current state, and how, and why, practice has developed as it has.

Design has consolidated upon the linear belt drive due to its relative simplicity and low cost, applying principals of mechatronics in order to maximise performance by way of sophisticated control technologies whilst minimising cost through simple mechanical arrangements using readily available components. It may though be argued that the approach, in pursuing low-cost and simplicity as its key attributes, has reduced performance levels relative to those provided by traditional designs.

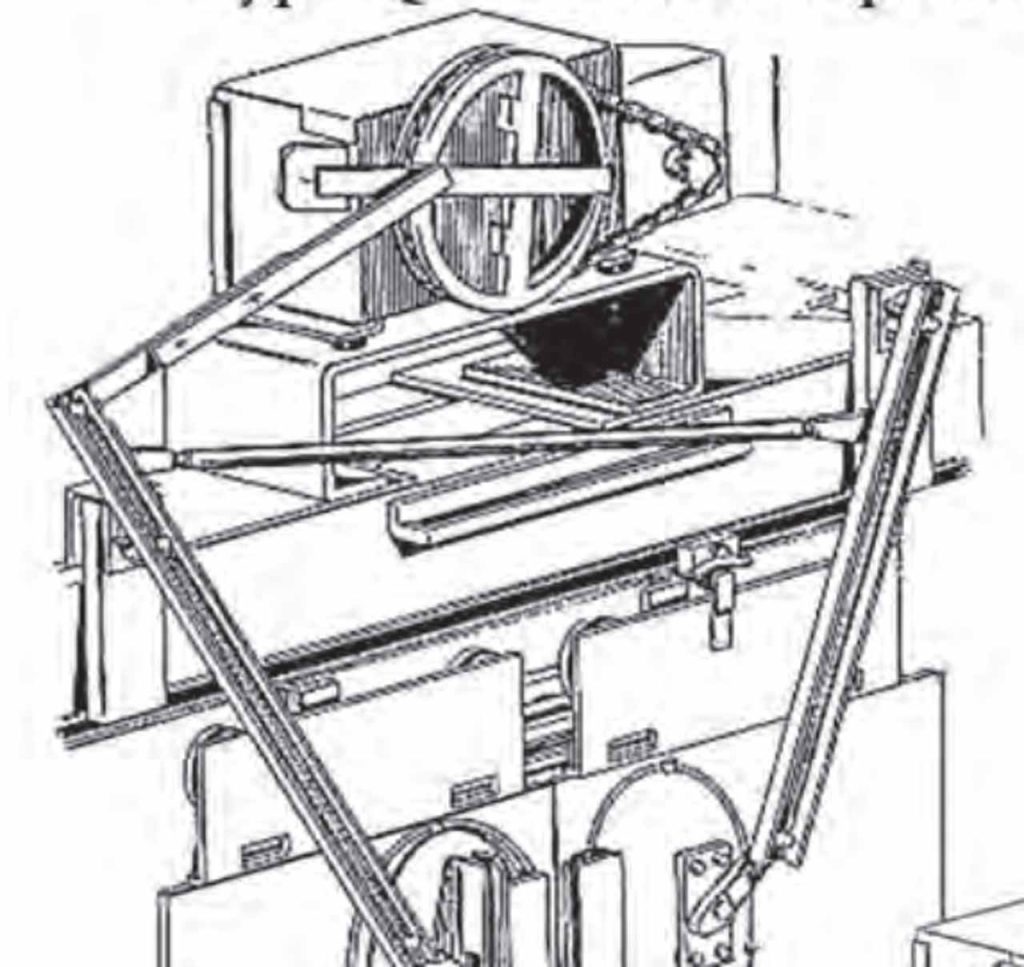

Traditional high-end harmonic operators provide the ultimate in performance, with high opening and closing speeds coupled with responsive reversal all of which of course come at a higher cost and increased electromechanical complexity.

Many traditional operators incorporated oil dampers or dashpots, which could be inherent to the operator itself or separately linked to the operator mechanism. These functioned to control and damp the final part of the open-and-close cycle.

Developments in the design of door couplers evolved to increase mechanical complexity in support of a simplification of interlock design. However, this increased complexity may result in reduced lift performance in terms of getting a lift car quickly to a floor, as the increasingly complex design inhibits a higher approach speed of the car to the landing.

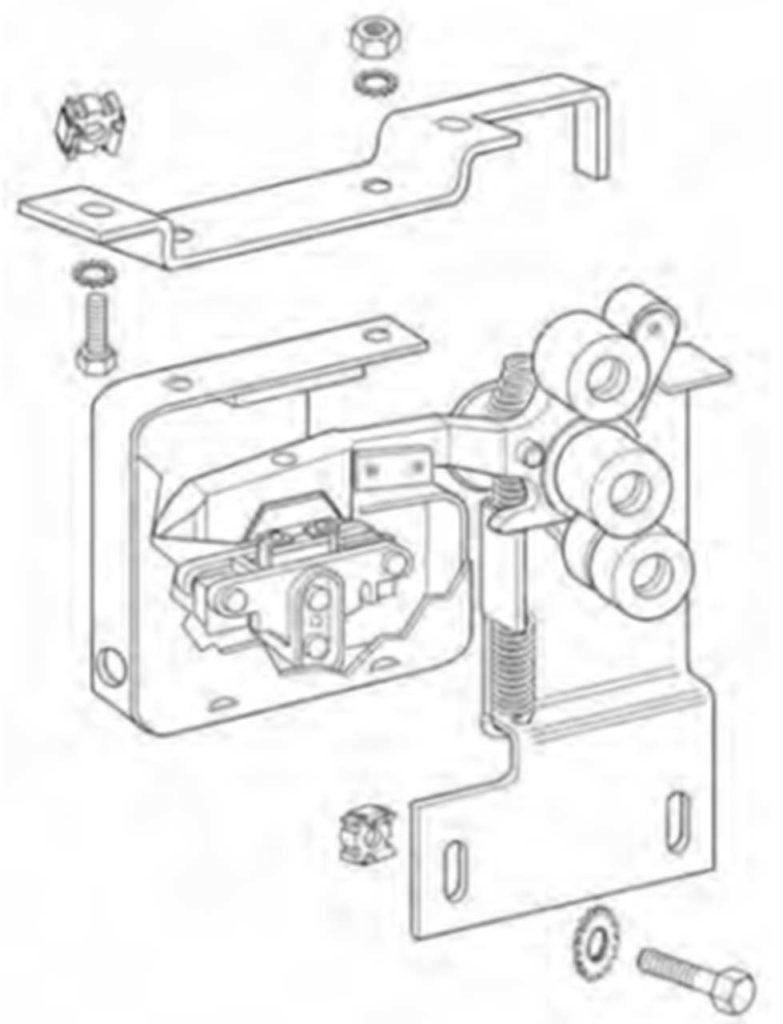

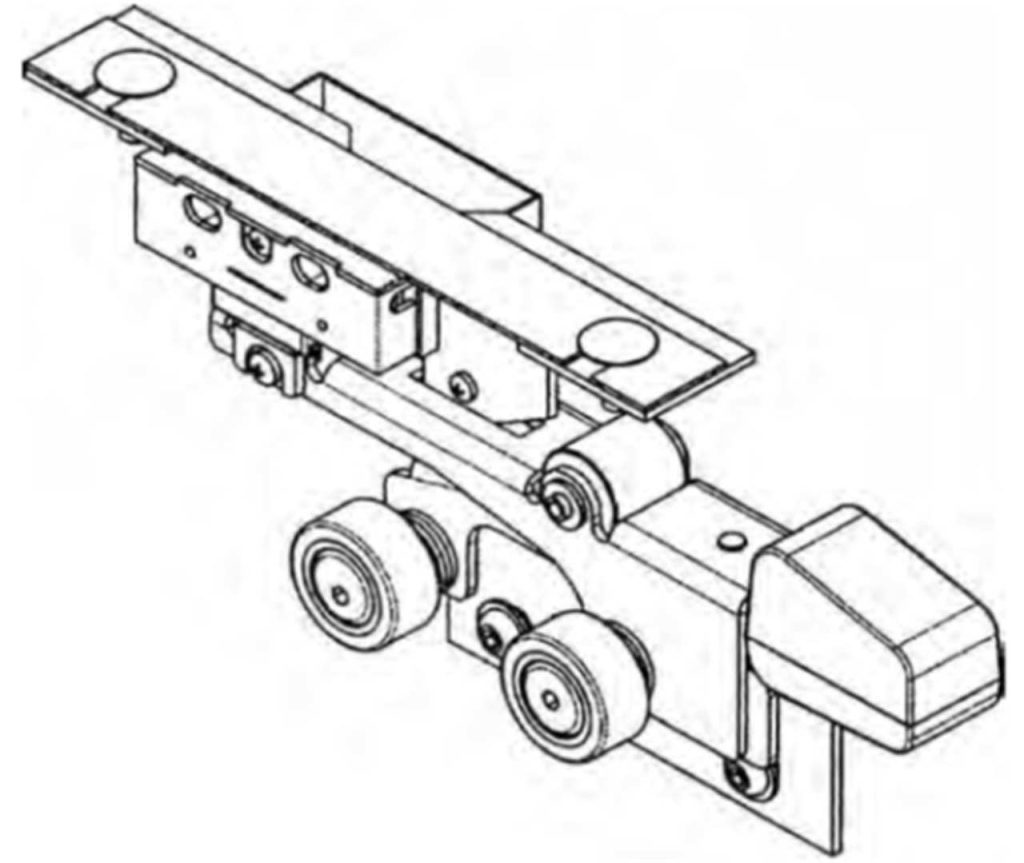

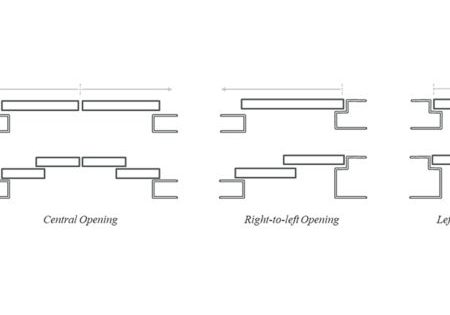

Developments in interlock design are such that these are now simplified and mass produced, reflective of a trade-off between the complexity and cost (Images 3 and 4) of the design of the door skate and that of the interlock. Given that a lift will be equipped with multiple interlocks this approach appears logical.

The interlocking of manually operated gates in the U.K. (with shutter type gates predominant in the U.K. and hinged doors in Europe) is based predominantly upon the Dewhurst VL range of interlocks. These have been in production for many years now and have outlived (and outsold) all prospective competitor and rival designs.

Whilst we have consolidated upon the Euro emergency release key, the design of associated operating mechanisms requires some consideration. Lift shafts must be kept secure, as well as be accessible for maintenance and emergency processes. In this sense, the design of the emergency release may be considered safety critical. Indeed, I have conducted a number of incident investigations in which the inappropriate use of a release key has resulted in a door becoming unlocked, or in the case of bi-parting freight entrances, opening automatically whilst the lift car was absent from the landing. In general terms, release mechanisms should be both simple and foolproof. Experience has shown that increased complexity more often increases the risk of failure. Whilst concerns have developed in relation to a perception of the access to emergency release keys being too-readily available my view is that the standardisation of the design has generally been positive and beneficial and in instances where a risk of unauthorised interference arises, the designer may apply the provisions of EN 81-71.

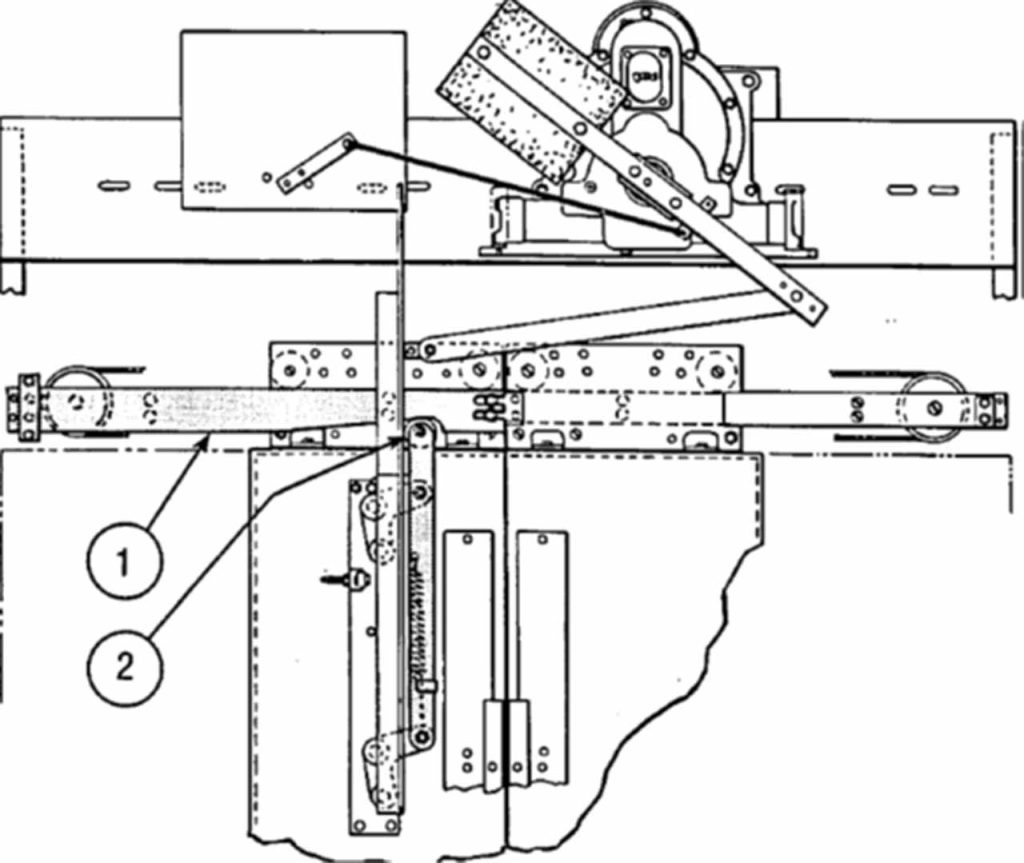

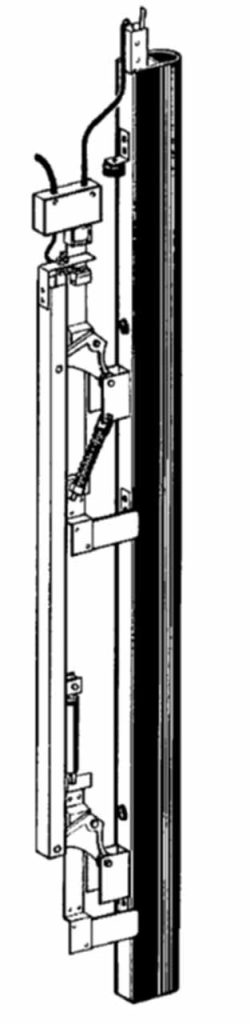

Vertical bi-parting doors used on freight lifts demand a particular form of safety system which operates to establish the position of the car at the appropriate landing and simultaneously to control the operation of the landing doors. This dual safety function, ensuring the presence of the car at the landing before the opening of the doors, has long presented something of a design conundrum, and in my experience, has been, and continues to be, problematic. Regardless as to the manufacturer, every system I have seen has its own inherent Achillies heel. Whilst I understand the engineering logic of the EN 81-20 requirement that the panels of powered vertical car doors/gates should be imperforate, my observation and overall gut feel is that when applied in practice, the closed car door/gate (which must close prior to the landing door/gate) obscures the view of the lift operator as to what is happening on the landing. A retrograde step in my opinion.

EN 81-20 introduced a sea-change in terms of requirements for automatic door operation and passenger protection, requiring, in effect, the non-contact detection of a person crossing the entrance during the closing movement. The state of the art is now based upon non-contact detection and protection. I recall advising in cases in which lift users suffered injury due to entrapment of, or collisions between, limbs and moving elements of closing doors. Prior to EN 81-20, I was able to advise that a mechanical safety edge or contact sensor was adequate to meet the requirements of the law (excepting where higher protection was required, for example, for less-abled or aged passengers) and (subject to the system meeting the force and impact energy limits) that this was acceptable. The system was deemed compliant with no breach of the accepted state of the art. Post EN 81-20, non-contact detection during the closing cycle represents the state of the art.

Considering door safety, the 150 N maximum pressure (which can be traced back to the 1931 ASME A17.1 Code) and 10 J maximum kinetic energy limit (which has its roots in the 1955 ASME A17.1 Code) set out in EN 81-20 have been with us for many years now, and in roughly the same magnitudes from at least 1970. Similar forces and energy limits are reflected in other jurisdictions, albeit that the magnitudes may vary somewhat in order to reflect particular requirements relating to the strength of doors and other components. However, the empirical representation of the upper limits is questionable and appears to have been drawn from experience and a level of pragmatism, rather than from verified engineering theory (the 1958 BS 2655 Standard required that doors or gates on automatically operated lifts should be “so designed that their closing and opening is not likely to injure a person.”).

However, that said, the simple longevity of the 150 N and 10 J maximums, together with the relatively high number of door-related incidents compared to other forms of lift equipment failures, are such that the prospect of any change (which is likely to involve a reduction in maximums) is likely to prove contentious. Indeed, questions of engineering efficacy and legal certainty play a significant role in entrenching established maximum limits in our standards and regulatory systems. Whilst simple compliance is not in itself always sufficient in terms of a defence in case of accident or injury, noncompliance is almost certainly fatal. Emerging technologies may though present opportunities for another look at the safety of lift door operation.

Indeed, I have conducted a number of incident investigations in which the inappropriate use of a release key has resulted in a door becoming unlocked, or in the case of bi-parting freight entrances, opening automatically whilst the lift car was absent from the landing.

In the 1970s, Otis’ balanced bridge detectors led the market, although the technology had been developed years earlier and, with aerial technologies based around 220 V at high frequency, could present a very real electric shock hazard. The most effective alternative, applied in the main in hospitals and healthcare environments, lay in light-ray photodetectors.

However, these were mounted upon the car door panels and subsequently prone to alignment and contamination issues. Image 6 shows an Otis rubber safety shoe which was fitted to the front edge of a car door and which, in the case of physical contact with an obstruction, operated a microswitch to reverse the doors. I recall how problematic these were in comparison to detectors in terms of physical damage, failed flex cables and broken linkages and fixings. Given that operational damage was more often chargeable to the client, lift contractors may mourn the passing of this design, albeit I was glad to see the back of it.

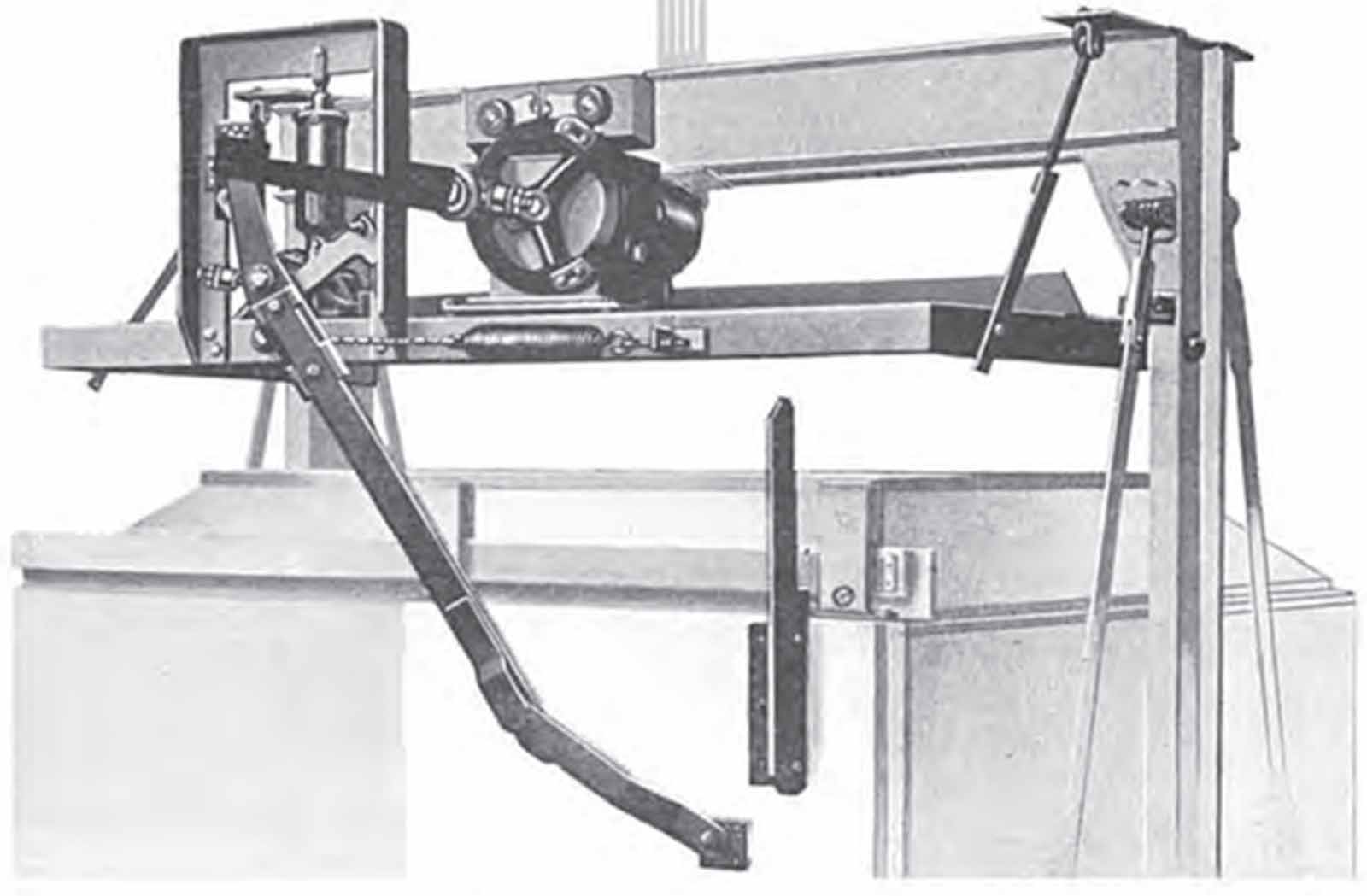

Otis initially adopted DC injection braking to control AC-driven operators until this was replaced by Otis’ saturable reactor-controlled 6970 operator, which was widely applied to provide exceptional performance in relation to speed and responsive reversal during the close cycle. Similarly, Schindler’s QKS series applied injection braking to complex harmonic mechanisms to achieve similar performance. Image 5 shows an Otis 6970 Saturable Reactor operator which incorporates a cam and follower-operated retractable coupler. This functioned to advance the front edge of the closing car door ahead of the landing door such as to facilitate the advance operation of the door detector and enhance safety.

As the OEM majors now subcontract their door/entrance production to specialist manufacturing firms, we are perhaps observing the commoditisation of the door system element of lift manufacture.

Having worked in the industry for almost 50 years now, I regret the reduced engineering diversity which has arisen as a result of the consolidation upon the linear-belt design, albeit that some of these products incorporate technologies which provide superior levels of performance whilst others are relatively poor.

So, what of the future? Well, the incorporation of AI together with advanced sensor technologies is likely to improve the efficacy of door protection and may well enable the 3D detection systems which, to date, have met with only limited success. Whilst advanced sensor technologies have previously been applied, these lacked the associated processing sophistication and intelligence to make the systems robust in terms of discriminating against false triggers and identifying real passengers accessing and egressing the lift car.

It is also likely that AI applications will extend to the control of operator torque and speed, and subsequently door pressure and force, together with car and landing entrance condition and performance monitoring such as to enable effective predictive maintenance.

Get more of Elevator World. Sign up for our free e-newsletter.