Modular Design

Jul 1, 2025

A way to optimize installation efforts and costs

by Fabrizio AielloIn the fast-growing North American elevator industry, with more than one million operating elevators and a market value of US$28.6 billion in 2024 (ELEVATOR WORLD March 2025), the demand for cutting-edge and efficient solutions has never been more urgent.

Rising labor costs and critical component delivery time and costs recently highlighted the importance of efficient and fast installation and maintenance. Can optimization offer the same, or better, performance and quality without oversized equipment? The answer is YES. Through proper analysis and multifactorial calculations, it is possible to select the appropriate machine for all needs.

In 2024, a new approach emerged — delivered by Montanari North America Inc., the new subsidiary of Montanari Group, renowned manufacturer of Italian-made traction machines, launched to timely serve North American markets. With more than 50 years of experience in designing and producing high-performance geared and gearless machines, safety devices and components for elevators, Montanari challenged the old-fashioned approach, proposing new design solutions and rigorously tested technology.

Modular design, tailor-made solutions and smart machine configurations offer industry consultants and professionals a different experience in selection, ease of installation and costsmaintenance. Whether it’s offering cutting-edge solutions for new installation in high-rise buildings, providing easy-to-maintain systems for older residential structures or supporting challenging modernizations in critical sites, Montanari has the expertise and a CSA-certified range to meet every challenge.

Modular Design: A Game-Changer for Installation and Maintenance

One of the standout features of Montanari’s approach is its modular design philosophy, which transforms how elevator systems are installed, maintained and modernized.

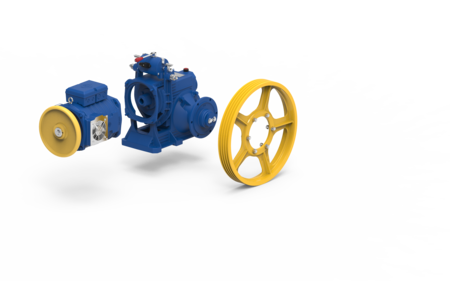

Montanari’s modular geared machines are designed for flexibility, enabling components to be easily disassembled into its three primary sections — motor, gearbox and traction sheave — without voiding the warranty. This feature is particularly advantageous for new installations in confined space sites or when modernizing outdated elevator systems.

In most challenging modernization projects, particularly in older buildings with limited access to machine rooms, the ability to break down the machine into smaller, lighter parts makes transportation and installation much easier and faster. The modular design then lets elevator professionals handle the installation more efficiently and safely, reducing installation time and associated labor costs.

Self-Centering Couplings: Ensuring Precision and Ease of Assembly

Montanari addresses another common industry concern: the fear of losing critical settings when disassembling the machine. With self-centering couplings and an in-house advanced assembly process, Montanari eliminates the need for manual adjustments during reassembly, ensuring that each component is perfectly aligned. This innovative self-alignment feature gives installers full confidence in an easy and proper reassembly process, without risking performance degradation.

Each Montanari traction machine also has its own unique QR code that provides instant access to digital manuals, installation guides and troubleshooting resources. Having 24/7 access to detailed, step-by-step instructions helps professionals optimize installations and reduce errors.

Streamlined Maintenance: Effortless Upkeep and Extended Lifespan

The advantages of the modularity also optimize the maintenance phase, offering easy access to critical components and ensuring long-lasting, reliable performance over time. The machine design features:

- Three easily accessible inspection windows that allow technicians to quickly monitor the oil levels, check the condition of the worm screw and inspect the bronze crown gear — all without oil spillage.

- Eccentric flanges that provide the ability to compensate for wear between the screw and gear, allowing for simple adjustments that help extend the machine’s lifespan.

- Components such as the brake, encoder and motor are designed for quick, efficient replacement with easy-to-follow guidelines for technicians to replace worn parts in under 1h.

For elevator maintenance teams, improved speed and simplicity means less time spent on-site and lower labor costs, as a single technician can carry out maintenance tasks that previously required a team. This reduces operational disruptions, as well as time out of service, leading to higher user satisfaction.

Timely service is crucial and elevator companies that are able to quickly address breakdowns are more likely to retain customers and expand their maintenance portfolios. To enhance the speed and competitiveness of industry professionals, Montanari guarantees its technical assistance and Italian-made traction units and spare parts — now readily available in North America thanks to its strategic partnership with Triumph Electrical, utilizing its extensive warehouse network and industry expertise.

Compactness – A Matter of Space and Sound

The recent move toward more efficient and compact traction machines offers the opportunity to rethink elevator design. Increasing old buildings’ value is the new challenge for engineers and architects. Requalifying rooftop space is essential, yet often difficult to access and fully leverage.

Gearless machines with reduced sizes make the most out of existing elevator shafts, allowing the transformation of old machine-room (MR) elevators into new machine-room-less (MRL) systems. The accessibility of the rooftop is then restored without major structural or construction work.

And what about an MRL elevator system with the motor close to the top-floor apartment? Given it’s usually the most prestigious in the building, noise levels become a critical factor for elevator users, tenants and the building’s reputation. Cutting-edge gearless machines, such as the Montanari machines, solve this challenge due to the extremely quiet operation of both motor and brake.

Exceptional Engineering and Quality

To exceed and set new industry standards, Montanari selects only high-quality materials for its components and machines, which are nearly 100% manufactured in-house. The hardened ground worm screw and centrifugal bronze crown gear are designed for quiet operation, increased durability and superior performance.

Every Montanari machine undergoes stringent testing, from the initial raw materials to the final product. Testing includes 3D measurement tools; optical scanners for dimensional checks and surface analysis; noise testing chambers to ensure sound levels meet the strictest international regulations; electrical tests to guarantee safety and performance under all conditions; and a test bench to check machines’ performance at 100% torque load and speed.

Comprehensive Product Range

Montanari North America offers a broad and versatile range of geared and gearless traction machines, all CSA certified and designed to cater to the unique needs of both new installations and modernization projects. The Geared Machines (M Series) supports MR installation covering up to 6000-lb carry capacity and 600 ft/min speed. All of the machines can be supplied along with a specifically engineered bed plate, guarding solution and custom deflector sheave. The Gearless range (MGA34) features quiet and energy-efficient solutions, ideal for MRL installations and equipped with CSA-certified motors and brakes.

A Legacy of Innovation: From Italy to North America

Montanari’s legacy began in 1970 in Italy where the company humbly started in a garage, producing handcrafted traction pulleys. With a vision to create more efficient and technologically advanced elevator systems, the company rapidly grew, producing its first gearbox models for the local and international markets. The rapid expansion of product range and facilities paved the way for Montanari to become a global leader in elevator traction machine manufacturing and industry expertise.

After decades of continued innovation, Montanari North America brings this legacy of excellence to North America, enabling local elevator professionals to benefit from high-quality, modular machines designed for the modern age and most challenging installation needs. We’ve engineered our machines for global reliability and tailored them to North American standards. We’re here to support elevator professionals every step of the way.

Get more of Elevator World. Sign up for our free e-newsletter.