Back to Its Roots

Jul 1, 2025

SnapCab launches high-end custom division amid continued growth.

by Kaija Wilkinson

images courtesy of SnapCab

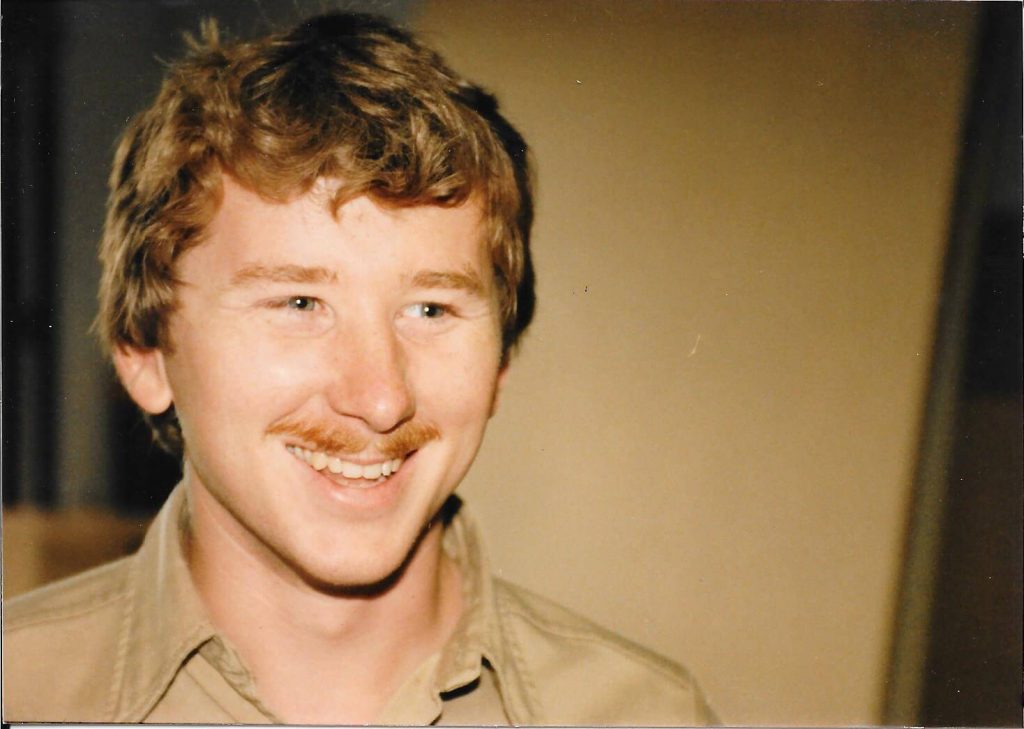

Made entirely by hand at the company’s 56,000-ft2 facility in Warrington, Pennsylvania, the booth SnapCab presented at the United Convention & Exposition in Atlantic City, New Jersey, in September 2024 stood out from hundreds of others, receiving the National Association of Elevator Contractors’ Best Island Booth award. Open on all four sides and accessible from any direction, the booth invited attendees to take a trip through time with SnapCab, from its early beginnings in 1983 as founder Glenn Bostock’s high-end custom furniture and cabinet shop to the well-known elevator interior and office pod manufacturer it is today. On display were large color photographs of evolving city skylines and SnapCab products. All the photographs shone because they were behind optically clear Corning® Gorilla® Glass, a material used often by SnapCab.

In addition to its easy-to-install, high-quality elevator interior systems tailored to fit any cab size or style, SnabCab manufactures an array of meeting pods, privacy pods and phone booths. SnapCab serves elevator maintenance companies, business owners, architects and consultants.

Revolutionizing the Industry

In 1995, SnapCab “revolutionized the industry” with the invention and patenting of its InterLocking Panel System, later renamed SnapCab, making elevator interior installation faster, easier and more reliable. Its efforts were rewarded with an exclusive contract with Otis. Successful collaborations with component suppliers would follow, including Corning Gorilla Glass in 2014. A few years in, SnapCab had already “made hundreds of cabs (incorporating Gorilla Glass), with demand increasing each month,” according to SnapCab’s director of architecture at the time (ELEVATOR WORLD, June 2016). In 2016-2017, SnapCab began designing privacy pods.

SnapCab’s patented system of interlocking panels, for which the company is named, will remain its flagship product, but with the launch of Bostock Custom by SnapCab — which boasts 365 years of craftsmanship on staff — the company is ready to embrace spending up to a week or more on a single job. “We have done custom work since the beginning, but we are expanding our offerings and saying ‘yes’ to a lot more custom requests,” Bostock observed. “We are working with many existing customers who have a lot of custom needs.”

Return to a Niche, High-End Market

SnapCab’s newest division is being led by Chief Operating Officer Joe Danko and represents a return to its roots: When Bostock’s young company first pivoted to renovating elevator interiors in 1989, it focused mainly on the “very small, niche” high-end market. Danko said SnapCab is “thrilled to embrace the creativity and uniqueness of custom work once again” with Bostock Custom.

The company has invested in new equipment to support Bostock Custom, including a wide belt sander to create panels to the exact, desired thickness; a spray booth where any finish — including custom stains and lacquers — can be applied; and a veneer guillotine and stitcher that can apply veneers to substrates so it looks “exactly like a solid piece of that species of wood.”

In Growth Mode

Fueled by the popularity of its elevator interiors and award-winning privacy pods, SnabCab is in growth mode as it invests in new equipment, hires and physically expands — in both the U.S. and Canada. Bostock said:

“We have grown our metal shop with CNC (Computer Numerical Control) manufacturing equipment and handrail equipment. We are offering more in the way of cladding. We are always investing in new equipment, but what’s really exciting is we’ve built a school for educating business leaders and salespeople about the business of elevator interiors. We’re empowering elevator maintenance companies to add interiors to their core competencies.”

When it comes to elevator interiors, some elevator maintenance companies are missing the boat, Bostock said. Most, he said, seek to grow through economies of scale, trying to expand territories and stretching their sales teams. “Elevator remodeling is an example of increasing revenue through economies of scope — offering more products to the same customers,” Bostock said.

The company continues to evolve and thrive, and has come a long way from Bostock’s original core team of two. Back in the 1980s, Bostock said, he had a hard enough time managing two people. Today, SnapCab’s payroll surpasses 135 people as it grows rapidly. Bostock attributes this success to “our method of managing as a ‘human business,’ where we put the employees and customers first.”

SnapCab is ready to scale up its custom department. It has fully implemented Lean manufacturing practices at its facilities in Kingston, Ontario, and Warrington, Pennsylvania, and is “now in a position where we can pay better than before for higher-skilled workers,” Bostock said.

Employees — 90 in the U.S. and 45 in Canada — will soon be joined by additional colleagues as the company adds space for production and sales teams. The Canadian branch in Kingston, Ontario, is adding 18,000 ft2 to its 36,000-ft2 location.

Challenges and Silver Linings

As it grows, SnapCab deals with challenges that also have silver linings. Tariffs, Bostock said, have had some negative impact because the company is affected in both the U.S. and Canada, “but we’ve been fortunate in that it has stretched our vision.” That means expanding its customer base in Canada, and, for the first time in company history, it is looking to expand into Europe.

High turnover in the elevator industry, meanwhile, means that SnapCab must continually educate new people and build new relationships. Having an in-house training facility makes that easier, Bostock said, continuing:

“We train people on the same systems that Toyota uses. Now that we’ve fully implemented Lean manufacturing, we are a model company that others tour to learn about Lean. Everything we’ve learned in our standard product line we are revisiting as we scale up the custom department.

SnapCab has multiple national accounts with customers that include airports and major hotel chains that need effective branding. For this, the company frequently uses Gorilla Glass on the rear cab wall that incorporates the client logo. The company has produced more than 350 such branded components for a single client. The reason SnapCab is such a good fit for Corning Gorilla Glass is “that they are quality-focused, innovative and, more specifically, focused on customer needs and requirements,” said Hank Dunnenberger, who retired from Corning a few years ago.

Bostock’s Upcoming Book

Bostock has no plans to retire anytime soon, as he focuses on promoting a better work culture in what he calls “A Human Business” — “a new paradigm of work that involves putting customers and employees first,” he said. When he’s not running SnabCab, Bostock might be found putting the finishing touches on his upcoming book, Becoming A Human Business, set to be published by Forbes Books in 2026.

SnapCab, Bostock said, has “wildly exceeded” his expectations. He said:

“Back in the 1980s, I thought I’d always be working in a little woodshop. But, since around 1998, the focus went from craft to the opportunity to do elevator interiors. I changed from focusing on custom, high-end working to building a scalable company of workers who are engaged in the final products.”

Now, SnapCab is offering more with Bostock Custom, delivering for customers of all kinds and increasing revenue through its economy of scope.

Get more of Elevator World. Sign up for our free e-newsletter.