Improving Efficiency and Reducing Cost of Ownership

Sep 1, 2025

A new compact escalator drive series from Renold Gears

by Simon Thompson

For high-traffic escalators, power transmission solutions must deliver the highest standards of durability, efficiency and quiet operation. This demanding context is where Renold Gears, part of the international engineering group Renold plc, excels. For more than a century, U.K.-based manufacturer Renold has been synonymous with long-life products, earning the trust of industries worldwide through a commitment to quality and high performance.

Renold’s new compact escalator drives are designed to deliver optimal performance across a motor power range of 11 kW to 75 kW. The range includes:

- A light-duty vertical single worm (VSW) for commercial and transit escalators

- A medium-duty vertical worm helical (VWH) for public and transit escalators where space is at a premium

- A heavy-duty horizontal single worm (HSW), for major underground transit escalators

Our range of escalator gearboxes ensures a robust drive solution for every escalator type.

At the center of Renold’s compact escalator drive series is the VWH140, a vertically driven worm helical reduction gearbox suited for high-traffic mid-tier escalators.

Benefits of VWH140

VWH140 is engineered to set new benchmarks in the urban mobility sector with efficiency, reliability and space optimization, along with significantly reduced maintenance needs.

Compact Design

VWH140’s compact and vertical design addresses the imperative for maximizing space within urban infrastructure development. This vertical configuration is particularly advantageous for in-truss installations, allowing the drive to fit snugly within an escalator’s structural framework. This minimizes the footprint and simplifies installation, even in the tightest spaces.

VWH140’s design is further optimized by offering three footprint options, ensuring hassle-free interchangeability with drives from other manufacturers. This makes it a drop-in alternative for both new installations and critical retrofit projects, eliminating the need for extensive re-engineering or redesigning of existing infrastructure.

Advanced Gearing Technology

At the heart of VWH140’s performance lies its sophisticated gearing system. The high-speed input stage features Renold’s worm gearing. This advanced worm gearing is then coupled with helical gearing on the second stage. This WH combination sets it apart from traditional SW or single-helical designs. This hybrid approach leverages the distinct strengths of both:

- Worm Gear Stage: Delivers high reduction ratios within a compact space, ensuring smooth and quiet operation.

- Helical Gear Stage: Provides an additional high-efficiency reduction stage with high power density, significantly enhancing the overall power transmission capacity and ensuring consistent performance under continuous heavy loads.

This dual stage gearing combination results in an efficient drive capable of delivering the required torque and speed in a compact package. Renold’s comprehensive catalogue of escalator drives covers motor power ranges from 11 kW up to 75 kW, with a flange-mounted motor option for applications over 30 kW capability. The Renold VWH140 specifically covers a motor power range of 18.5 kW up to 30 kW.

Operational Benefits

The Renold VWH140 is engineered to provide tangible operational benefits for OEMs and end users alike. Its design addresses the need for enhanced efficiency, reliability and sustainability.

High efficiency and energy savings: Optimizing power consumption translates into reduced operational costs and a smaller carbon footprint for urban infrastructure. For end users, this means reductions in electricity bills; while for OEMs, it offers a compelling argument for a lower Total Cost of Ownership.

Low noise and vibration: The Renold VWH140 delivers significantly quieter operation thanks to the inherent smoothness of its worm gearing combined with the loadspreading engagement of its helical gears. This is a crucial factor in commercial and public spaces where noise pollution can detract from the user experience and impact surrounding environments.

Reduced downtime: VWH140 achieves advanced reliability through several key innovations. Renold’s low-oil technology is a technical differentiator. It is unlike traditional gearbox designs that require larger oil volumes and operate with higher oil levels. This approach significantly reduces the volume of lubricant required within the gearbox. Less oil means less churning, which directly leads to reduced operating temperatures. Lower temperatures prolong the life of the oil itself, extending oil change intervals and reducing maintenance frequency. This also minimizes thermal stress on internal components like bearings, gears and seals, ultimately extending their operating life and enhancing the drive’s reliability and uptime.

Leak-free design: Complementing its low oil volume, the VWH140’s leak-free design featuring optional non-contact labyrinth seals is a key differentiator. These advanced seals are crucial in preventing lubricant leakage, a common challenge with older or less sophisticated gearbox designs. Oil leaks not only create potentially hazardous conditions but also necessitate frequent top-ups and clean-ups, adding to maintenance work and operational costs. By using a sealed, contained lubrication system, VWH140 reduces downtime from oil leaks for end users and minimizes environmental impact.

Ease of Installation and Maintenance

Renold’s VWH140 design prioritizes simplicity and efficiency in installation maintenance.

Interchangeable footprint: A major advantage of VWH140 is its drop-in interchangeability with gearboxes of the same standard footprint. Its three footprint options ensure it can replace existing drives from various manufacturers or be easily integrated into new escalator designs without complex re-engineering of the truss or motor mounts. This reduces installation time, complexity and associated costs for OEMs and simplifies retrofit projects for end users.

Reduced Lifetime Costs: The VWH140 delivers:

- Lower lifetime costs through a powerful combination of low-oil technology (which extends oil change intervals and reduces oil expenses)

- High operating efficiency (which reduces total energy consumption)

- Leak-free operation and extended component life due to reduced operating temperatures. For end users, this translates into significant benefits like lower spare stock levels and reduced maintenance times.

Adaptability and customization: The Renold VWH140 can be customized to suit procurement specification features that might be specific to some escalator designs and operational requirements.

Proof of Performance – Efficiency, Noise and Payback

The advantages of VWH140 have been quantified through extensive testing and comparative analysis. Before releasing VWH140 to the market, the Renold team ran a series of tests against alternative products on the market across a range of price points. For the basis of this article, the names of these products have been removed.

The testing was conducted across a range of operating speeds and applied output loads. Input and output torque was monitored using high-accuracy torque transducers throughout the gear unit warm-up phase until stable temperatures were reached.

Executive Summary of Test Results

Across the full range of applied powers, VWH140 demonstrated lower power losses and noise levels than other worm-helical geared alternatives. Compared to bevel helical geared competitors, VWH140 demonstrated significantly lower noise levels while also exhibiting lower power losses up to around 30% of its rated power — this is very relevant when considering that escalators operate at lighter loads most of the time.

Detailed Test Results

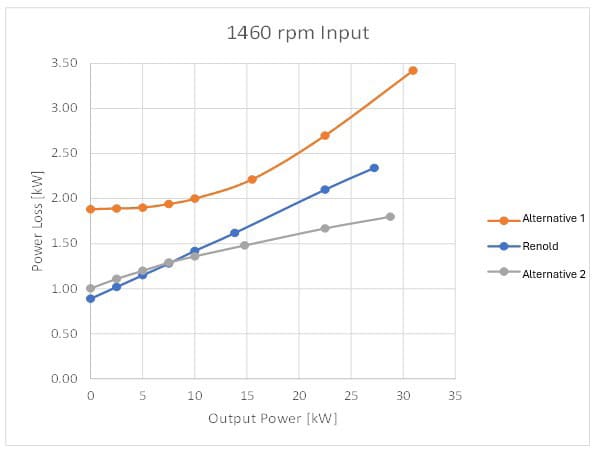

Quantitative efficiency advantage: Under testing, when measured at 1460 rpm input, VWH140 demonstrated clear leadership in efficiency and power loss.

Power loss: The Renold VWH140 exhibited significantly less power loss across the entire output power range compared to Alternative 1, other gearboxes tested. For instance, at 30 kW output, the VWH140’s power loss remains below 2 k, compared with nearly 3.5 kW of loss from one alternative. For end users, this directly translates into less wasted energy and lower operational costs.

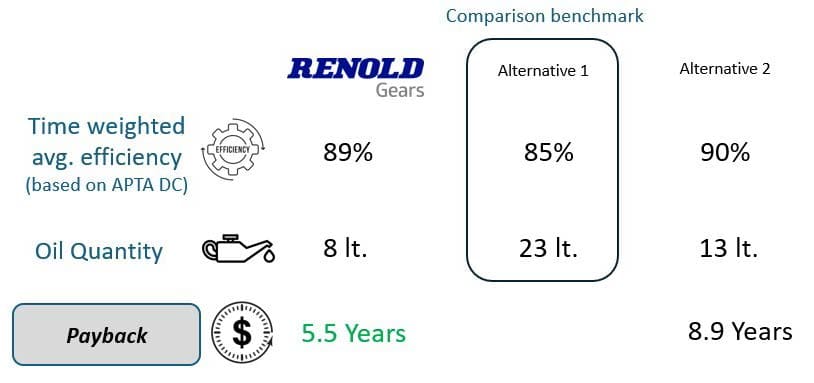

Overall efficiency: VWH140 delivers exceptionally high efficiency (consistently over 90%) throughout the power range, consistently outperforming one alternative. It is as efficient as another comparable drive up to 50% power, demonstrating competitive performance across varying loads. Based on a time-weighted average efficiency (derived from the APTA duty cycle), the VWH140 achieves 89% efficiency. This compares favorably to one alternative at 85% and is nearly on par with another at 90%.

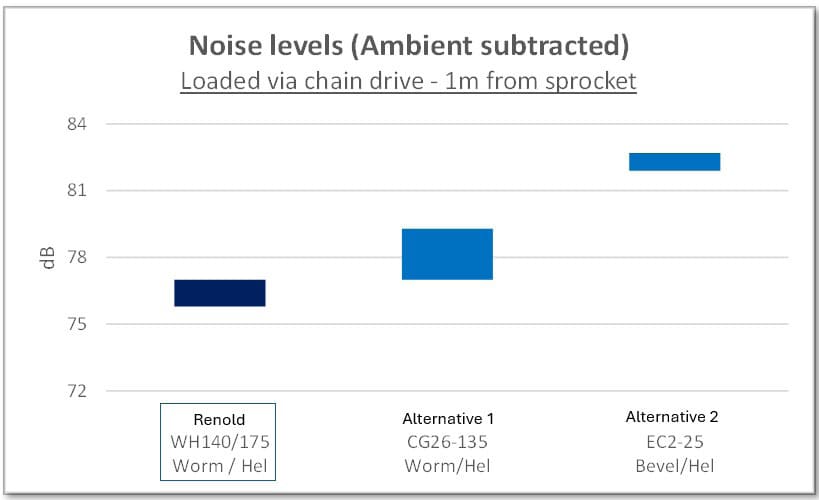

Superior noise performance: The smoothness of the Renold worm gearing and precision manufacturing contribute to demonstrably quieter operation. Quantitative noise level measurements provide clear evidence:

- Renold VWH140 exhibits noise levels between approximately 75.5 dB and 77 dB.

- In contrast, one alternative (worm/helical type) operates at approximately 77.5 dB to 79 dB.

- Another comparable drive (bevel/helical type) demonstrates significantly higher levels, ranging from 81.5 dB to 82.5 dB.

These comparisons show that the VWH140 drive is quieter than the alternatives tested, providing a tangible benefit for any application where acoustic comfort and adherence to noise regulations are priorities.

Accelerated Payback Period: Beyond technical performance, the most compelling outcome for end users is the accelerated return on investment. The combined benefits of high efficiency (leading to lower energy consumption) and reduced maintenance costs (from low oil and leak-free technologies) translate into operational savings.

Comparative analysis demonstrates this clearly:

The Renold VWH delivers a quicker payback period of just 5.5 years. In comparison, other drives tested showed 8.9 years for cost savings to recoup the initial investment. renold.com.

Get more of Elevator World. Sign up for our free e-newsletter.