111 North Canal Street, Chicago

Feb 1, 2016

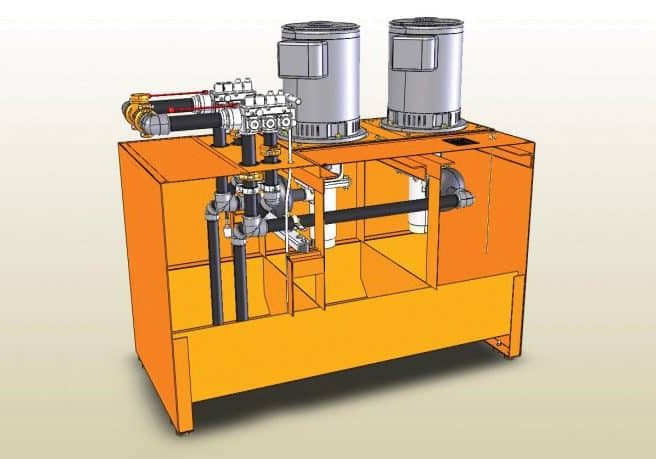

MCE provides an innovative solution to a modernized warehouse.

“It is hopeless for the occasional visitor to try to keep up with Chicago. She outgrows his prophecies faster than he can make them.” – Mark Twain, 1883

The Great Lakes town of Chicago was incorporated in 1833 with a population of just 350 determined souls. By 1848, the Illinois and Michigan Canal opened a water link for shipping between the Great Lakes and the Mississippi River, and the Galena and Chicago Union Railroad came to town. Chicago started a race toward the future. The city reversed the flow of the Chicago River and built the first skyscraper in the U.S. in 1884. It is home to merchandising giants Sears, Roebuck and Co. and Montgomery Ward and the starting point of U.S. Route 66. While 50% of U.S. rail freight passes through Chicago today, the city is also one of the nation’s largest aviation hubs.

Chicago embodies change. It is a city in which a warehouse, such as the 16-story building at 111 North Canal Street built in the early 1900s, can transmogrify into a vibrant, highly connected, state-of-the-art, Leadership in Energy & Environmental Design Gold certified home to latest-technology companies like Gogo, Uber, Twitter and Fieldglass. The building was designed and built for commerce. Surrounded on three sides by bustling thoroughfares providing wide-open access to a centrally located group of 10 freight elevators and facing the shipping traffic of the Great Lakes, the building efficiently received, stored and shipped all types of goods across the nation by ship, rail, truck and, in time, air.

Ninety years passed. Business was moving faster. Building security became a necessity. A new kind of commerce moved into the River Center building at 111 North Canal – one that moved quickly, dealt mostly in information, depended on instant communication and demanded the same kind of performance from its business environment – including building elevators – as from themselves.

A Modern Solution

The elevators in the building were last modernized approximately 40 years ago. Mitsubishi Electric, U.S. with consulting by Mike Eden of Syska Hennessy took on the job of bringing them up to the current demanded performance level. Given the design requirements put forward by building owner Sterling Bay Cos. and architect Proteus Group, Jim Bohac of Mitsubishi Electric and Eden of Syska Hennessy decided to bring in Motion Control Engineering, Inc. (MCE) to provide destination-dispatched iControl AC and DC elevator controls for the central group of 10 elevators.

The high-tech occupant companies demanded the building be renovated to 2015 standards, with particular emphasis on the outdated elevator system. They pointed out the 10 elevators were arranged back-to-back, so, only half were visible from any one perspective. They were dispatched as five duplex installations, caused security delays and provided a poor passenger experience.

MCE replaced four geared machines with new AC gearless machines and refurbished six retained Haughton DC gearless machines running at 700 fpm and using 12-pulse silicon-controlled rectifier drives. It modernized one Otis “Turtleback” car switch and a manual freight-door unit. It installed a new geared Hollister-Whitney 64 overhead machine weighing 7000 lb. and running at 450 fpm.

Challenges

The challenges of this deep modernization were both hardware and software centric.

Hardware

The original 10-passenger units were initially five-car switch freight units modernized in the early 1980s as five duplex groups. A staged-unit modernization was employed to meet time constraints, and scheduling according to the rigid timeline was a critical site problem. With different door sizes, heights, sills and pass-type doors on some units, the original door systems were atypical between each group. The car-frame assemblies and car-door opening configurations and sizes were different between each duplex group, and there were material-handling issues for all units on site. The new geared machines were hoisted on the first completed new service unit. All new entrance door panels were installed on all units, and all entrance assemblies were clad in 4-ga. stainless steel.

New nickel and silver sills were installed at new elevations on all lobby entrances, and all new electric service was needed for all units. Every car was physically roped for the approximate 195-ft. rise of the building, yet different units serviced different landings and lower levels. The service unit was demolished completely, including the wooden counterweight rails. New counterweight brackets and additional main rail brackets were required for speed and capacity changes, from a 5000-lb. car running at 200 fpm to a 7000-lb. car running at 450 fpm. New entrance assemblies for custom passenger-style height and depth were fitted beneath the existing structural members, replacing the biparting freight doors on the service unit. The pit on the service unit had to be deepened for the new contract speed.

The International Union of Elevator Contractors Local #2 mechanic-in-charge and approximately five additional mechanics and five apprentices provided the technical muscle under Mitsubishi Electric leadership. Together, they planned, timed and executed the installations so adequate elevator service to the building was maintained. They wanted to start with multiple groups, so they took down the first bank of four cars all at once, leaving six in service. Once the first four cars were ready, the iCue dispatcher initiated destination dispatch for those cars. In turn, an additional group of four cars and then the final two were replaced and folded into the now 10-car destination-dispatch group.

Software

At first blush, it may seem a modest proposal – an elevator system of 10 cars serving multiple companies occupying 16 floors of a 20-landing building. But, the technical challenges would require significant software additions to the architecture of the MCE iCue dispatching system, a new serial interface to proprietary security software and communications optimization to ensure that real-time background data interflow would not impact the coordinated performance of the elevators. There was a need to direct passengers to particular elevators, since no location provided the ability to see all 10 cars in the passenger group. The software challenges included:

- Moving existing dispatching from selective/collective to destination dispatch in logical groups

- Providing destination dispatch of all 10 cars from a single dispatcher

- Providing elevator access and passenger flow directed around a newly secured, directed-entry 10-car layout originally intended for open access from any of three major thoroughfares

- Providing an elevator-assignment system that favored cars visible from each of the two secured entry areas

- Interfacing to a Computrols security system through their third-party serial protocol

- Providing turnstile-automated, proximity-triggered floor and car assignment, in addition to standard kiosk assignment

- Ensuring all access and floor assignments are cleared by the building security system

- Employing a combination of serial hallway annunciators at upper floors and custom, discrete active displays in the lobby

- Providing a remote configuration/diagnostics application that includes aspects of the third-party security-system settings

To meet these challenges, MCE provided:

- An MCE iControl iCue dispatcher with expanded capability software

- MCE remote technology allowing for secure monitoring and configuration via Internet connectivity

- Six iControl DC elevator controls

- Four iControl AC elevator controls

- Four Imperial Electric 525 AC permanent-magnet gearless machines

- 10.4-in. touchscreen destination-input devices with embedded proximity card readers

- 6.5-in. turnstile destination assignment and direction screens

- Dual door-jamb-mounted 4.3-in. position indicators for each car

- Custom, ceiling-mounted and standard mFlag hall annunciators with lanterns

- Custom discrete outputs to drive the large lobby-car identifiers

Advanced Technology

Ten Destination-Dispatched Cars, One Dispatcher

This installation may be the only single-dispatcher, 10-car destination-dispatched elevator group in the U.S. One dispatcher was desired due to the physical nature of the elevator arrangement, coupled with the requirements that cars have different bottom-floor offsets and provide service to different sets of floors. This dictated a need for passenger- and elevator-traffic coordination MCE determined was achievable only by employing a single point of control. Eden commented,

“While it is highly unusual to group 10 elevators that are not all visible from one another, traffic simulations indicated a single 10-car group of elevators with destination-based dispatching controls provided better service than the original four-car low-rise and six-car high-rise groups.”

The elevator area was open before the modernization. Now, building-security requirements dictated controlled access from two directions, necessitating two traffic flows be managed, while providing access to any car. Each of the six entrances to the elevator area is accessed through glass-panel turnstiles with proximity sensors. As a passenger enters the turnstile, their security card is scanned, providing the dispatcher with the passenger’s identity and preferred destination floor. The glass panels open, and the turnstile screen displays the elevator assignment, along with a map to the car.

A new car-layering algorithm was added to existing iCue operating software to only assign a passenger to one of the cars visible from the point of entry. In case none of those cars is available, the map to the assigned car switches to a top-down view, and the passenger is directed “around the corner.”

There are times when a known passenger or a building guest might want to select a destination floor other than a preferred assignment. To accommodate this, each bank of elevators has a standard destination-input kiosk. Destination input devices, both turnstile and kiosk style, also support Americans with Disabilities Act compliance.

Turnstile Access Control, Destination Style

Interconnection between elevator and security systems is often accomplished using a complex nest of wiring that limits future expansion and functionality. In this case, MCE and Computrols developed a network-based connection that allows for the use of Computrols CBAS access control. Passenger data goes directly to Computrols’ building security, and each passenger’s level of entry is determined exclusively by the Computrols system.

Access control can read regular employee badges and handles temporary paper security passes printed for visitors. This installation marks the first time turnstile security has been paired with the MCE destination-based dispatching system.

Computrols vice president of Operations, Andrew Mire, commented,

“The project was one which required extreme coordination and teamwork from all parties involved… Through close coordination, we were able to bring the vision to light. The coordination between MCE and Computrols engineering and project management teams was seamless. Computrols could not have asked for a better group to work with.”

Remote Access

MCE iControl systems and iCue dispatchers are Ethernet enabled. The MCE iView PC application provides local or remote Internet access from anywhere an Ethernet/Internet connection is available. Through iView, a technician can request and be granted access to any Internet-connected iControl installation. Once access has been approved by machine-room personnel, iView provides not only extensive diagnostics capabilities, but also the ability to make changes to system configuration and even to AC and DC motor adjustments.

In addition to the standard iView software, MCE also provided iMonitor, an elevator monitoring and control application, and iReport, a specialized report-generation and information-archiving application. Like iView, both provide local or remote Internet access from anywhere an Ethernet/Internet connection is available.

The modernization was completed on time. The lobby design by Proteus Group is dramatic, featuring bold lighting and translucent towers that light in different colors with the time of day. The functional design of the security turnstiles neatly mirrors the appearance of the elevators. Beyond aesthetics, the turnstiles and screens had to collect data, not only for the iCue dispatcher, but for the Computrols building-security system, as well. The new lobby and elevator system provides the perfect welcome to a high-tech building.

Project manager David Rutledge of Leopardo Companies said,

“It was a pleasure working with MCE and Mitsubishi throughout the entire process. I have been a part of the testing after completion, and can say that the system worked as sold and as expected. Computrols played an important role in the process as well, and the collaboration between the two teams was seamless.”

Get more of Elevator World. Sign up for our free e-newsletter.