Schindler helps rebuild the WTC site by completing aggressive schedule for landmark tower.

With Silverstein Properties’ announcement of the 4 World Trade Center’s (WTC) grand opening on November 13, 2013, no firm could have been prouder than Schindler. Following 9/11 and the winning of his company’s 99-year lease of the WTC site from the Port Authority of New York and New Jersey, Larry A. Silverstein, founder and chairman of Silverstein Properties, vowed after the attack that his legacy will be the rebuilding of the site. True to those words and with major cooperation from nearby municipalities and America as a whole, Silverstein Properties built the state-of-the-art building, which includes leading building safety standards for high-rise commercial buildings.

As with everything at the WTC site, the grand opening of this prestigious building was spectacular, including the New York Philharmonic Orchestra performing on the outside infinity set back on the 57th floor to introduce the building to the Manhattan skyline. Senior Project Manager Jerry Piserchia and Project Executive Glenn Rodenheiser, both of Schindler, were on hand that day. They had been involved in 4 WTC since 2007, when attempts were first made to secure these projects for Schindler. Then, Silverstein Properties (along with Tishman Construction Corp.) was knee deep in the rebuild of other parts of the WTC site, which included thousands of aspects of all trades, engineering and architectural design. Piserchia remembered the many hours put in to composing a bid for towers 2, 3 and 4. District Operations Manager Andy Werkhoven recalls having met with Silverstein on occasion, including the final meeting for awards of towers 3 and 4 for the vertical-transportation system. Werkhoven remembers the intensity of the meetings and negotiations but felt the group, as a whole, had the underlining objective to rebuild the site to prove to the world that America cannot be beaten, and they were all proud to be part of that effort.

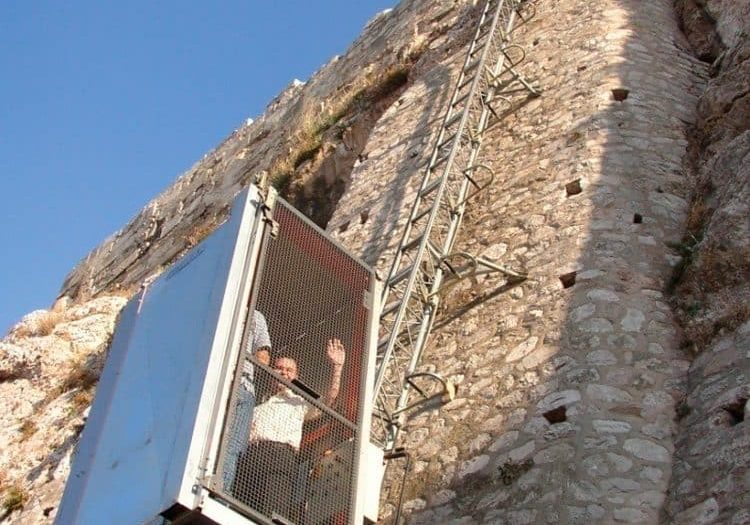

The celebrations were short lived at Schindler upon the award notification, based on the aggressive tower construction schedule put forth by ownership and Tishman. Vast retail space at the site and the fact that it is becoming a massive transit hub also raised the stakes. Schindler Elevator had been awarded the retail complex job, consisting of eight traction elevators, two hole hydraulic elevators and 10 escalators. This massive environment will span some five levels below street grade. Piserchia stated that the project was an effort put forth not only with direct and routine communication with Schindler U.S. corporate headquarters in Morristown, New Jersey, but also in with the company’s headquarters in Switzerland.

Once Schindler had both its corporate headquarters design team and local New York design team in place, meetings commenced to start the design and engineering of the vertical-transportation system. Ownership was sold on the equipment’s features and benefits, starting with Schindler’s PORT destination-dispatching technology. The gearless units installed include the Schindler 7000 elevator system. Schindler’s focus on seamless quality of ride was also highly valued by the ownership. This was effected in part by Sematic door operators on all passenger and service cars in the building, except the F1 two-stop hydraulic car. Interactive roller-guide components and a cab shell design with car-top shrouds also contributed to the solution. Full cab mockups allowed the entire interiors to be experienced before full manufacturing.

Your author reviewed the tower with Schindler and Silverstein Properties representatives, who were happy to show its 38 passenger elevators, including three service and one hydraulic elevator, and two escalators. Rodenheiser indicated it took hundreds (if not thousands) of hours of engineering to get the systems to their high level of quality. Challenges along the way included weekly construction meetings with Tishman to review every aspect of Schindler’s performance and progress during the installation, which started in January 2010. These meetings took place across the street at 7 WTC, where there was a telescope set up to be used during the meetings to visually confirm concerns or items being discussed. During the height of its work, Schindler had more than 40 representatives onsite performing and supervising the installation. This number included a dedicated district operations manager (Werkhoven) and a project manager, Candace McGinty, who were responsible for the day-to-day operations of the Schindler team. Assisting them were Superintendent Pat Dineen and his job foreman, Sean Murphy.

The SPI Construction, Inc. and Tishman teams worked with Schindler on the project as the construction of One WTC (ELEVATOR WORLD, November 2014) was going on. In preparation for the detailed and complex delivery schedule to the jobsite, all equipment was initially gathered in Newark, New Jersey. Schindler’s creative methods to streamline construction included bringing delivery trucks into the lobby of the building and a trolley into the temporary lobby to unload and lift the elevator rails off the trucks for their placement at the stacking area. Piserchia stated that it was not easy to keep track of all the supplies, engineering and personnel in the three-and-a-half years of installation but credits the success to the weekly meetings with all Schindler personnel to update them on the project’s status, goals and objectives.

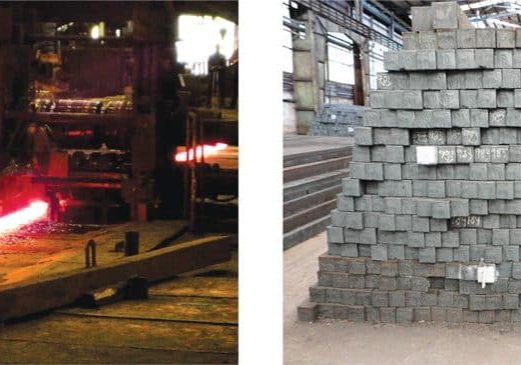

Routine process and projects audits were conducted by Schindler’s Morristown, New Jersey, quality-assurance department to ensure the engineering goals and objectives of the Schindler teams were being met. These reports were distributed among the engineering and field teams so that adjustments could be performed and progress could be benchmarked. This included detailed reviews of the rail stacking, particularly the “A” bank, which included the first elevators to get up to full speed. Schindler recreated a simulator on the third floor for tracking the rail and bracket installations.

Detail in the cosmetic approach to the project included the latest fixtures available for the PORT system and a very complex cab design to meet the vision of both the architect and ownership. As with any high-security building, confidential procedures and equipment were put in place to ensure the proper protection of the building occupants. This started at the lobby in the vertical transportation system with the PORT system’s integration into the lobby security turnstiles. With the lobby desk overlooking the National September 11 Memorial & Museum, there is a constant, stern reminder that security in this day and age is at the forefront of building owners’ and managers’ minds.

Alex Riveira, vice president of WTC Operations for Silverstein Properties in charge of 4 WTC, spoke of his experience with the towers and Schindler, complimenting Schindler on its professionalism and responsiveness to the needs of the owner. Riveira was the Silverstein Properties operation department intermediary for the transition from construction to daily operations. He was involved in transition meetings for all critical systems of 4 WTC, including the vertical-transportation system. JB&B Engineering was the lead engineering team for the project and worked with architect Fumihiko Maki.

Particular attention to detail was paid to the complexity of the machine-room components and their location. As a mechanic enters a motor room, he or she should immediately notice a screen displaying all the details of the bank of elevators with which that room is associated. Next to the screen is a PORT fixture the mechanic can use to enter calls to recreate traffic conditions and monitor elevator performance. As for safety systems, safety stop switches were installed on the platform gearless machines. Additionally, the sheave underneath the machine is greased through fittings at machine level for ease of access. Finally, the machines have unique safety features, including the ability to move the elevator in a total power failure.

Having been part of the WTC towers when Silverstein Properties was awarded the lease, your author felt an overwhelming sense of pride and gratitude at being back. The commitment by all companies and individuals involved in the construction of this beautiful building is something of which every American and elevator-industry member should be proud. The passion and dedication to rebuild as expressed more than 10 years ago by Silverstein is coming to fruition. In this case, the old saying “If you build it, they will come” should be revised to “If you build it with a passion, dedication and a commitment, they will not only come, but they will come in droves.”

Get more of Elevator World. Sign up for our free e-newsletter.