Latest edition of the Field Employees’ Elevator Testing Manual puts ASME A17.2-2020 Guide for Inspection of Elevators, Escalators and Moving Walks in users’ pocket.

At 136 pages, the pocket-sized fifth edition of the National Association of Elevator Contractors’ (NAEC) Field Employees’ Elevator Testing Manual is not even a quarter of the length of the American Society of Mechanical Engineers (ASME) A17.2-2020 Guide for Inspection of Elevators, Escalators and Moving Walks. The spiral-bound handbook tells vertical-transportation (VT) professionals who perform tests on electric and hydraulic passenger and freight elevators in the presence of certified elevator inspectors in very concise, clear terms exactly what they should be doing and where to find further information within the code. Reviewed and revised according to the most recent code — ASME A17.2-2020 — by NAEC Global Education and Safety Director David Smarte; retired elevator professional and member of the Elevator World, Inc., Board of Directors Bobby Schaeffer; and VDA Vice President of Codes and Standards Greg DeCola, the newest edition is dedicated to the late Robert L. Seymour, who passed away in 2010. Seymour served as chairman of the ANSI/ASME A17 Standards Committee for more than 25 years and authored the original Field Employees’ Elevator Testing Manual, among many other publications.

It is essential that VT professionals performing tests understand what is being tested, why it is being tested and a safe means to absolutely demonstrate the function. The text of the handbook is designed to assist in this effort. The volume does not cover machine-room-less elevators, which are unique conveyances for which testing and inspections must follow manufacturers’ procedures found in on-site Maintenance Control Program, or MCP, documentation.

Sections on personal safety and test tags/documentation precede Parts I-VII: Part I, Category One Periodic Test of Electric Elevators; Part II, Category Five Periodic Test of Electric Elevators; Part III, Acceptance Testing of Electric Elevators; Part IV, Category One Periodic Test of Hydraulic Elevators; Part V, Category Three Periodic Test of Hydraulic Elevators; Part VI, Category Five Period Test of Hydraulic Elevators; and Part VII, Acceptance Testing of Hydraulic Elevators. According to Smarte:

“Younger elevator professionals, in particular, like the fact that it tells them exactly what, for example, a category five periodic test of a hydraulic elevator is, what they are supposed to be doing and all the related symbols and references, as well as where they can find more information.”

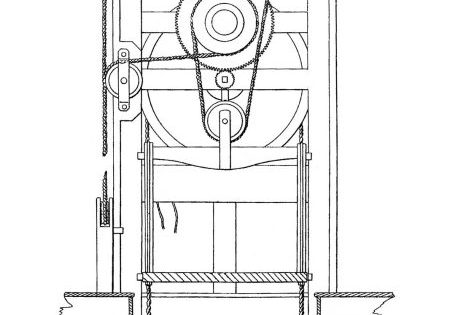

Each part has multiple sections. For example, Part I, Category One Periodic Test of Electric Elevators, includes sections on Door Closing Speed and Firefighters’ Emergency Operation, as well as on which pages these sections can be found. Drawings and illustrations help deepen understanding of buffer testing, safety devices, dynamometer connections and slide marks on guide rails.

The handbook concludes with a five-page Weights and Measures section, which includes equivalents for cubic, dry, liquid, imperial, long, mariners’, square, weight, volume and temperature measurements. A list of measurement abbreviations is also included. The fifth edition of the Field Employees’ Elevator Testing Manual is available for US$24 at elevatorbooks.com.

Get more of Elevator World. Sign up for our free e-newsletter.