A Maritime Milestone

Oct 1, 2016

thyssenkrupp plays vital role in global economic game changer, the first-ever expansion of the Panama Canal.

There is no denying the significance of the Panama Canal expansion to the global economy. When it wrapped up in June after nine years of construction, the US$5.25-billion project ushered in a new era for international maritime trade by nearly doubling the waterway’s capacity to container ships able to carry up to 14,000 containers.[1] The new ships are known as New Panamax, and they are the way of the future. Approximately three football fields in length and three times the size of the previous vessels, they will carry “90% of everything”[2] people need, from clothes to food to furniture and gasoline.

The project represents the first time the Panama Canal has been expanded since it opened in 1914, allowing ships to avoid swerving around the tip of South America and, instead, pass straight through Central America.[3] The expanded canal saves shippers both money and time. A tanker of liquefied natural gas, for example, traveling from the U.S. Gulf Coast to Asia, can shorten its travel distance by 5,000 nautical mi. and seven to nine days.[1]

The system works like a “giant water elevator” in that ships coming from either the Atlantic or Pacific sides enter a set of locks with chambers and are then lifted into the manmade Gatun Lake and, finally, lowered onto the other side.[4] The expansion, one of the largest engineering feats of the 21st century, added a third set of locks, each 1,400 ft. long, 180 ft. wide and 59 ft. deep. According to the Panama Canal Authority (PCA), the numbers involved were staggering and included:

- More than 100 economic-viability studies over six years

- Four gates (two for each lock), weighing 2,300 T each

- Excavation of more than 26 million m3 of material

- The addition of 1.4 million m3 of water to fill the New Panamax Channel, an area covering 1,300 acres.

- Dredging of more than 4.6 million m3 from Gatun Lake.

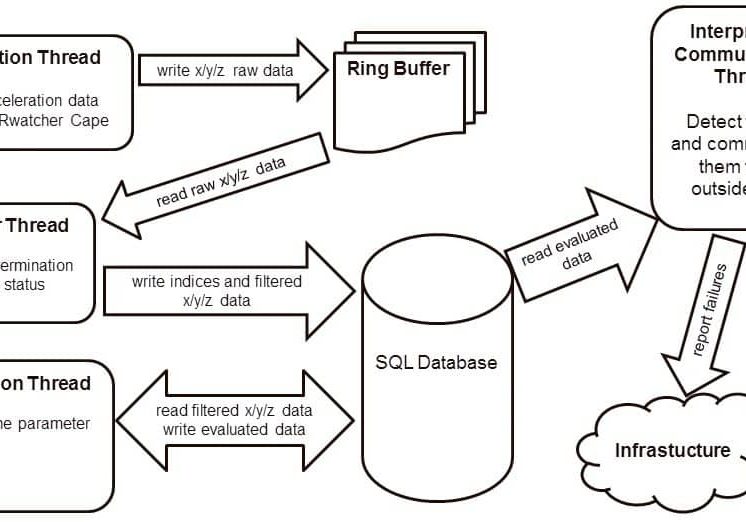

Safely and efficiently navigating such a massive and complex structure is no easy feat and is as vital to the system’s operation as the circulatory system is to the human body. That is where thyssenkrupp comes in. In the relatively short timeframe of five months, the OEM delivered 14 highly specialized, waterproof, explosion-proof elevators to Grupo Unidos por el Canal, SA, the contractor that designed and built the locks. Making all components for the tunnel elevators explosion proof – a must to ensure uninterrupted operation – was the first job of its kind in Panama, incorporating electrical devices that prevent sparks. All equipment was supplied from thyssenkrupp’s Neuhausen, Germany, factory, with the company turning to local suppliers for items such as tools and safety gear.

Elevator installation commenced in November 2015 and finished in April 2016. Twenty-four thyssenkrupp employees, split between the Atlantic and Pacific locks, were deployed. Six elevators on each side descend to depths of 50 m and are connected to tunnels known as “crossunders” running beneath the lock chambers (which hold millions of liters of water). Another pair of elevators operate in the control towers on each side.

The vertical transportation system consists of:

- Two 900-kg control-tower elevators traveling at 60 mps, making six stops

- Four 449-kg crossunder elevators on the Pacific side traveling at 60 mps, making two stops

- Four 450-kg, crossunder elevators (two on each side) traveling at 45 mps, making two stops

- Four 450-kg crossunder elevators on the Atlantic side traveling at 45 mps, making two stops

Outfitting the new lock system with elevators added to a Latin American portfolio of which thyssenkrupp is justifiably proud, including an elevator that climbs to an altitude of 3,900 m for a mine within a Peruvian mountain. The canal project was one-of-a-kind, representing a first in both complexity and scale for thyssenkrupp. Peter Bjorn, vice president of New Installation and Modernization for the Elevator Technology division of thyssenkrupp Latin America, said the project is indicative of “the high level of proficiency of thyssenkrupp teams working on milestone projects around the world.”

thyssenkrupp Elevator CEO Andreas Schierenbeck added it is an example of the company “jointly addressing the challenges of mobility in complex environments.”

It is satisfying to think our elevator industry played such a pivotal role in such a landmark project, observed thyssenkrupp spokesman Michael Ridder.

The Panama Canal expansion has been a driver of job growth that is still yielding fruit, both in Panama and beyond. The PCA estimates more than 30,000 jobs have been created by the project since its inception, and a ripple effect continues.

Ports, particularly along the U.S. East Coast, are preparing for increased traffic from Asia, thanks to the expanded canal, by making adjustments to their infrastructure. The first carrier to pass through was the 9,472-container China Ocean Shipping Co. (COSCO) shipping vessel from China, which was renamed COSCO Shipping Panama in honor of the June 24 occasion. At least five more similar-sized ships were scheduled to traverse the canal between June 30 and July 8,[3] and by late June, 170 New Panamax vessels had booked reservations.[1]

The Port Authority of New York and New Jersey intends to spend US$1.3 billion to raise the height of an 85-year-old bridge to accommodate the New Panamax vessels, and by 2020, the South Carolina Ports Authority plans to dredge its harbor from 45 to 52 ft. In Panama, the metro, bridge over the canal, airport and electrical transmission system are all being expanded.[1]

The expanded canal clearly offers good tidings for both the global shipping and construction industries. Like many projects of such scope and complexity, all has not been perfect: it was two years behind schedule and over budget.[1]

All in all, however, entities involved consider the project a great success and engineering marvel. If there is any loser in this brave new world, it is the smaller container ships that, as a result of the expanded canal, have become virtually obsolete overnight.[3]

References

[1] Mufson, Steven, “An Expanded Panama Canal Opens for Giant Ships,” The Washington Post, June 26, 2016.

[2] George, Rose, Ninety Percent of Everything: Inside Shipping, the Invisible Industry that Puts Clothes on Your Back, Gas in Your Car, and Food on Your Plate, Metropolitan Books, Henry Holt & Co., New York, New York, August 13, 2013.

[3] Toobin, Adam, “Panama Canal Prepares for First Mega Containerships After Panamax Widenings,” Inverse, June 16, 2016.

[4] Challgren, Thor, “Panama Canal Expansion Complete,” The Acorn, June 23, 2016.

Get more of Elevator World. Sign up for our free e-newsletter.