A “New” Way to Weigh

May 1, 2015

Ways of doing work in the elevator industry are continually changing. With new technology comes new and potentially better ways to complete important tasks. In recent years, some new tools that work directly on or with the hoist ropes have seen expanded use by many installation and maintenance companies.

Your author has had a particular interest in ropes over the past decade and has had the chance to follow and personally witness the field use of a broad range of both new and previously offered tools. Initially related to hoist-rope installation, the opportunity to see more measurement tools has expanded. While past interest focused on the equalization of rope load (still incredibly important to know), we see from a practical point of view that elevator companies have a strong need to check and know the weights of cars (total elevator cabin) and counterweights (CWT). We particularly see this in preparation for modernization projects and in other simple adjustments where code authorities are grabbing that opportunity to check and ensure reasonable and safe system load balancing.

This article literally shares several years of experience with weighing cars using the Henning Mobile Weight Watcher System — a method of attaching deflection-type load sensors directly to the hoist ropes. Some interesting concepts have come into play over the course of our experience. One observation could be considered a bit of a revelation, based on time available, knowledge of experienced mechanics and the very simple but powerful pressures of time. First, one should be careful not to compare the Henning measurement method to the old way of hoisting a car and weighing with a scale; for various sound reasons, an objective comparison often cannot be made.

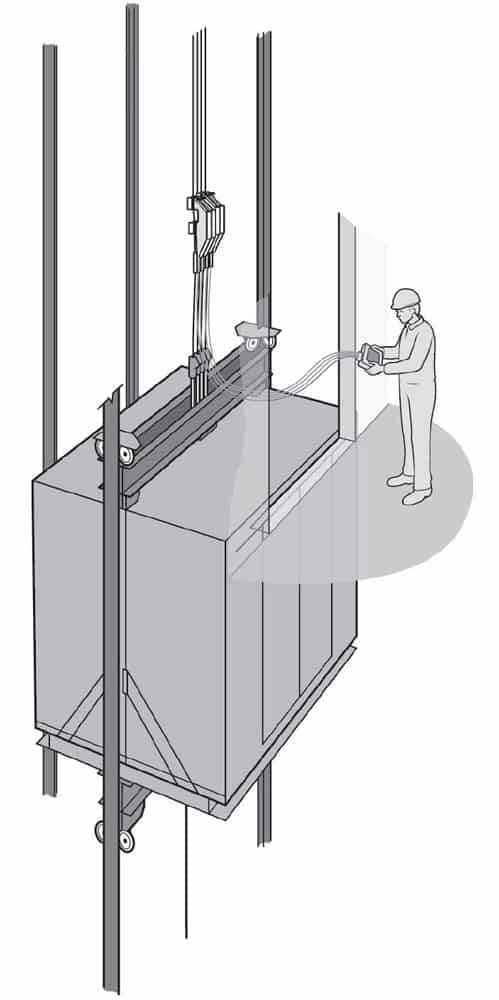

Many in the industry have always thought that following the old industry standard of hoisting a car, slackening the ropes and using a crane scale (or dynamometer) is an objective method of weighing. Indeed, Wurtec and other sources have, for many years, been supplying all the components needed for this procedure (Figure 1). Though the best method available for a long time, it could be very inaccurate, a fact most of us did not know. To make this method work, the weighing process has to be accounted for perfectly. In field practice, this is difficult to do.

This method demands that the car be picked up perfectly and balanced so that no part, including the guide shoes, can rest against or touch any part of the rails. Considering that a crosshead is rarely dead center on the car and that affixing a sling would shift the car’s center, being able to attain a truly balanced pick would require as much luck as skill. In addition, any newly installed elements after a modernization, such as a lighter door operator or cosmetic cab features (such as new flooring or mirrors) can change the car’s weight and balance, making the perfect pick even more difficult to obtain. Remember that even if a perfect pick is achieved with the ropes hanging free of the sheave assembly, some of their weight may still need to be accounted for, in addition to the weight of compensation ropes/chains/cables and traveling cables, in final car-weight calculations. This takes time, effort and maybe even some guesswork.

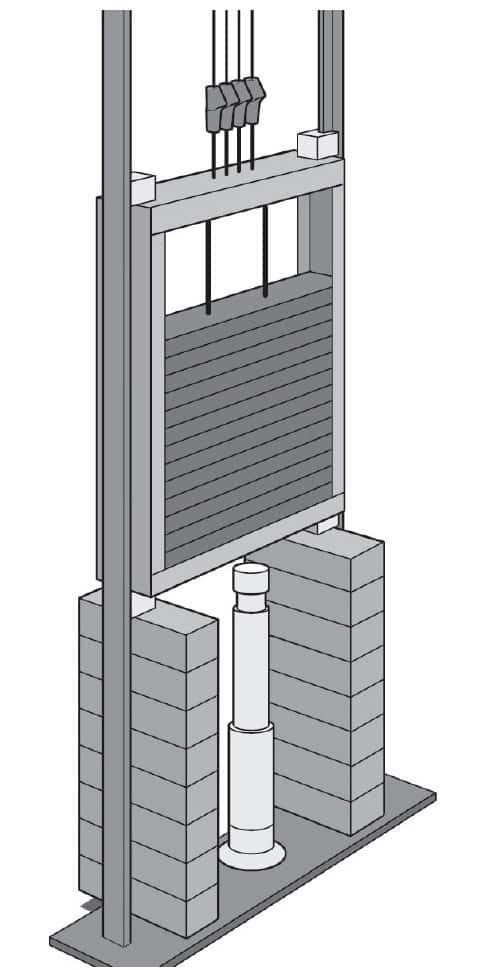

Additionally, some less-experienced technicians may forget to block (or land) the CWT assembly (Figure 2). Some even want to assume it is acceptable to take a shortcut and skip this important step. The CWT exerts force on the other side of the drive sheave, and its additional load can greatly skew any measurement taken. An elevator installation is not a static environment — it is a dynamic one. Each structural element impacts the system through friction or stresses. Anything that can exert force will impact the accuracy of the scale/hoist method.

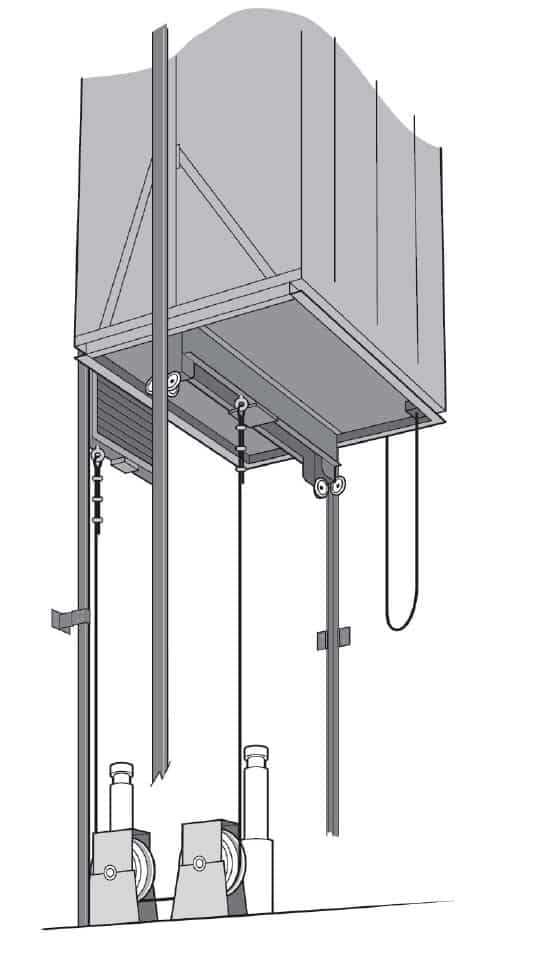

Whatever is under the car must also be added to the calculations. It is tough to make a perfect pick from atop the car due to structural considerations, and what is hanging underneath the car — traveling cable, compensation cable, compensation rope, etc. (Figure 3) — makes the process a little more complicated. If the elevator includes a tie-down system with a compensation sheave(s), then that load has to be negated if the hoist/scale method is going to work at all. Certainly, all these effects can be removed by releasing/lifting a fixed compensation sheave or detaching all the compensation ropes. But, factors like cost, time and even related safety risks make this a process most would like to avoid.

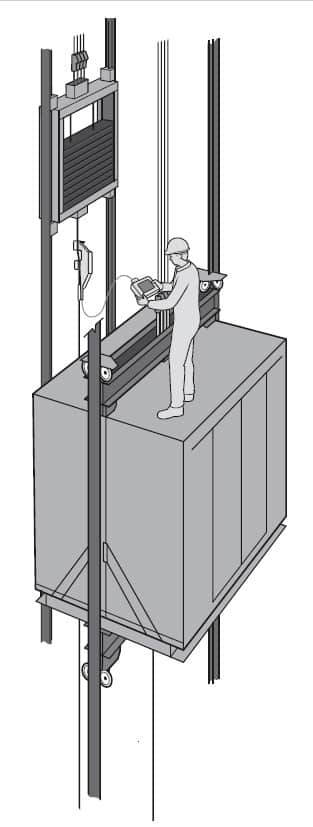

By contrast, only two steps are needed for a Henning Weight Watcher system to get an accurate weight of a car or CWT that has compensation ropes and a tie-down system. Obtaining an accurate weight requires applying one Henning sensor per hoist rope above the car hitch (Figure 4) and recording the measured force. Then, sensors are applied below the CWT (Figure 5). The difference between that measurement and the previous one will be the weight of the car.

It is important to use the right Henning Mobile Weight Watcher sensor for the job (Table 1). Inaccuracy can result when using a model beyond its weight measurement range. This can also damage the device’s sensors. Sheave groove depth variations (due to them being worn or manufactured unequally) can also impact the system’s accuracy and may have the same impact on other load-cell-type systems.

Variable sheave-groove depths create conditions in which some ropes in a set invariably carry more load than the other ropes (sometimes vastly more so). This could mean an overloaded rope could go outside the measurement range of a sensor. In this case, the system cannot “equalize,” or allow for that effect. Moving up to a larger sensor with a higher measurement range is the answer — typically, an LSM-XL model. This model is usually recommended in an effort to avoid this concern altogether. This ensures the Henning system gives results within the accepted/proven range of ±2.5% of the full scale of each sensor.

“±2.5% of full scale” is tied to the full-scale measurement of the sensors (scales) being used. Thus, a Henning LSM 1 Sensor (Table 1) has a full range of 1100 lb. 2.5% of 1100 lb. is 27.5 lb. An LSM-XL sensor has a larger full scale: 4400 lb. 2.5% of 4400 lb. is 110 lb. From this, the error range depends on the number of ropes being measured. For example, if there are six ropes (requiring six sensors), for the LSM1 sensor, actual weight will vary somewhere between 0 and 165 lb., either above or below. With the LSM-XL, the error range would be somewhere between 0 and 660 lb. When a car is accurately weighed on a single scale, users often think about 2.5% of what they are weighing — thus, for a 6,000-lb. elevator car, that would be 150 lb. An additional factor to understand with multiple ropes is that the statistical likelihood for all ropes (sensors) to be inaccurate all in the same direction (plus or minus) in the same measurement is very low. Thus, we generally think that maximum error on the large sensors would be half (or less) of the possible range.

Conclusion

Henning engineers have done a lot of measuring and testing to ensure accuracy and repeatability of the system, which is based on a patented principle. They have also had the product validated by an outside party. Most sources of error using the tool are due to either unintentionally using sensors past their load-measuring range or in some simple and correctable variances in user technique. For more details and information on the Henning device, Wurtec offers a full user’s manual or and a video tutorial. Your author is also open to any further questions.

Figure 1: The old hoist/scale method demands perfection and uses a shortening clamp, lever hoist, force scale and sling.

Figure 2: Attempting to make the hoist/scale method work requires landing or securely blocking the CWT assembly to remove any dynamic effect on measured load forces.

Figure 3: A tie-down system featuring a compensation sheave: all those elements under the car have to be accounted for to make the hoist/scale method work.

Figure 5: Place the tool below the CWT assembly, repeat the procedure and subtract that measurement from the previous one.

Get more of Elevator World. Sign up for our free e-newsletter.