An update on the construction of China’s newest supertall skyscraper

It is said that the under-construction Shanghai Tower is progressing by roughly a floor every five days. On April 10, the concrete pouring of the core structure in the tower was completed on the 108th floor at the height of 501.3 m, overtaking its two neighboring supertall skyscapers, Shanghai World Financial Center (492 m tall) and Jin Mao Tower (420 m tall). Forming a triad in the skyline of Shanghai with the above two supertalls in Lujiazui, Pudong, Shanghai Tower, the tallest of the three, will have a structure height of 580 m and total height of 632 m, with its 127 stories to provide enough office space for more than 30,000 people after its construction is completed in 2014 or 2015. With a total investment of around RMB15 billion (US$2.41 billion), Shanghai Tower is built on a land area of 30,368 m2 with a total floor area of 574,000 m2 on 121 above-ground floors and five underground floors. It will be a multipurpose complex, housing offices, convention and exhibition facilities, hotel rooms, restaurants, shopping areas, and entertainment and urban sightseeing facilities.

Shanghai Tower is a green building by design. Not only is it to be covered with lawns and trees (33% of the land around it), it is also to have a number of vertical gardens between its glass skins. Gensler of Los Angeles provided the architectural design, planning and consulting from its offices in Shanghai. It worked together with the Architectural Design and Research Institute of Tongji University to create Shanghai Tower’s main structure, which looks transparent with its vertically arranged urban neighborhood visible from the ground. On every floor inside the building, tenants and visitors are able to enjoy the varied views of the nearby skyscrapers and beyond the Huangpu River.

The building’s helical-lined opening goes from ground to roof, presenting a contrast with the architectural styles of the existing nearby Shanghai World Financial Center and Jin Mao Tower. Shanghai Tower has integrated both modern architectural concepts such as the double-skin configuration, and new building technologies, featuring an asymmetrical shape and using newly developed, eco-friendly building materials, which contribute to lowered construction costs. Technologies implemented in it include the installation of built-in wind turbine generators and a rainwater collecting system by means of the helical protection walls on the top of the tower. It is expected to receive Leadership in Energy and Environmental Design certification once complete.

Mitsubishi Electric and Shanghai Mitsubishi will provide 106 elevators for Shanghai Tower, with three of the elevators to be among the fastest in the world at the speed of 1,080 mpm (18 mps). However, due to pressure issues that may affect passengers’ eardrums during the descending ride at such a speed, it remains to be seen whether the lifts will descend at full speed. Likely, this speed will be limited to 600 mpm. Some of the fastest double-decker elevators in the world (at 600 mpm [10 mps]) are also to be installed.

It is said the design of the 18-mps lifts applied such newly developed technologies as super-streamlined car exterior fairing, flexible guide rollers to improve riding comfort and a car-interior air-pressure regulating system, which adapts the air pressure inside the car for passengers’ eardrum comfort by means of automatic sensors and a control unit. They are scheduled to shuttle between basement two and floor 119 (a rise of more than 500 m), each with a load capacity of 21 people. When going up, they accelerate gradually, approaching full speed in 25 s., then travel at full velocity for 10 s. or longer, before beginning to slow down for landing at the destination floor.

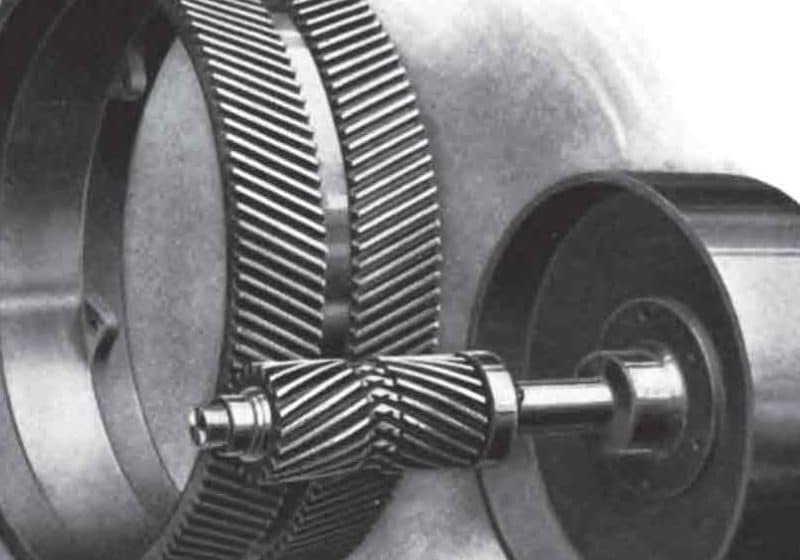

There were challenges in the design of the entire elevator system, especially in the car structure, drive capacity and safety components, requiring several new technologies (ELEVATOR WORLD, June 2013). The higher rises call for longer hoisting ropes, which increase the load of the traction machine. Therefore, a 310-kW, new-type traction machine equipped with ceramic braking material will be used. The material features both better wear resistance and heat shock resistance due to high physical performance under heated working conditions, specifically in the braking process. The ceramic braking material is also used on the specially designed safety gears, acting on both directions. The enhanced safety measures also include the installation of several 7.3-m, three-stroke telescopic buffers in the pits.

Other new technologies applied to the fastest elevators include Mitsubishi Electric’s sfleX-rope (EW, April 2012) traction rope, featuring high density and a lightweight coating with increased strength and breaking-load factor. The car is equipped with accelerating sensors to monitor the horizontal vibration levels in travel, with data feedback to generate reacting forces by the linear motors integrated in the rollers. In this way, the car vibration could be reduced to roughly one-third of the original level. The high lengths and weights of the traction ropes and traveling cables in the hoistway also posed challenges to the system design and are to be handled with other innovative solutions.

More than 100 skyscrapers over 300 m high were under construction around the globe in 2012, with roughly 60 more starting construction in 2012-2013. Therefore, the demand for super-high-speed elevators is estimated to be as many as 13,000 units by 2015, rising by 63% against the figure of 2010. China takes the lion’s share of the world’s total demand with 59%, followed by the Middle East at 14% and Southeast Asia at 11%. When complete, Shanghai Tower is to be the second tallest building in the world, behind the Burj Khalifa in Dubai. However, it is doubtful this record will be kept for more than one year, because at least two more megatall buildings under construction are to rise taller than it: the PingAn Finance Tower (660 m tall in Shenzhen) and the Greenland Center (636 m tall in Wuhan), also in China.

It seems these cities are competing in their height, and high-speed lifts have to follow up with the trend of the rapid development of such vertical cities. When 2004 saw the completion of the 508-m-tall Taipei 101, the tallest in the world at that time, Toshiba boasted supplying the fastest elevators in the building (1,010 mpm), then setting a Guinness World Record (EW, February 2005). However, the record will soon be broken with the installation of the three 18-mps lifts in the hoistways of Shanghai Tower. In addition, both the records of the fastest double-decker lifts and the highest elevator travel (565.4 m) will be set in the tower.

In regard to the challenges megatall skyscrapers face with emergency-evacuation issues, Shanghai Tower may become one of the first buildings to allow occupant evacuation operation by elevators, because running through the long staircases and/or using evacuation means from outside the building have been deemed ineffective at saving lives, especially for those trapped on the upper floors. The emergency-evacuation issues were taken into consideration in the design stage. According to Han Xin, researcher at the Shanghai Disaster Prevention & Rescue Institute at Tongji University, Shanghai Tower will be divided into nine vertical evacuation zones, each having an independent system to be used in case of disaster or an emergency situation, and all the zones will be fully covered by a video-monitoring system. There will be three firefighter elevators in the tower and 13 additional standby elevators for emergency-evacuation purposes. For example, in the event of fire, Zone 9 (the highest zone) will have two lifts dedicated to service, taking the occupants to the shelter area of the zone. On the middle floors where offices and hotel rooms concentrate, as many as three evacuation lifts will take people to the landing of the shelter area of each zone.

Sematic and Verri: A 50-Year Relationship

Sematic Lift Doors and Verri are linked by a longstanding partnership. Founders Francesco Zappa and Ermenegildo Verri, respectively, worked together during the early days of their firms, implementing lift door and car solutions now considered precursors of the modern “car package” concept. A close collaborative relationship since the 1960s benefitted both businesses. Over the years, Verri took on new technical challenges, such as the mounting of fixtures on sloping car walls. Through the deployment of advanced technologies, the brand successfully entered new markets and went on to produce such innovations as panoramic cars, and solutions featuring air-conditioning systems and armored glass.

Sematic began expanding widely in 1982 with the release of its “2000” family of doors with linear-belt-traction operators driven by DC motors through an analog electronic controller designed by Zappa (ELEVATOR WORLD, October 2009). Sematic acquired Verri in 2000 and made it the flagship for Sematic’s car segment as it launched a strategy of heightened quality across all of the Sematic Group’s components. Today, Sematic doors and Verri cars are installed in buildings of all types around the world. These products are designed to exploit the advantages of integrated design and benefit from the support of a manufacturing, sales and support network to meet client requirements for both standard and highly customized applications.

Get more of Elevator World. Sign up for our free e-newsletter.