A10 Tauern Tunnel, Austria

Jul 1, 2016

Alimak Hek undertakes elevator refurbishment in the Alps.

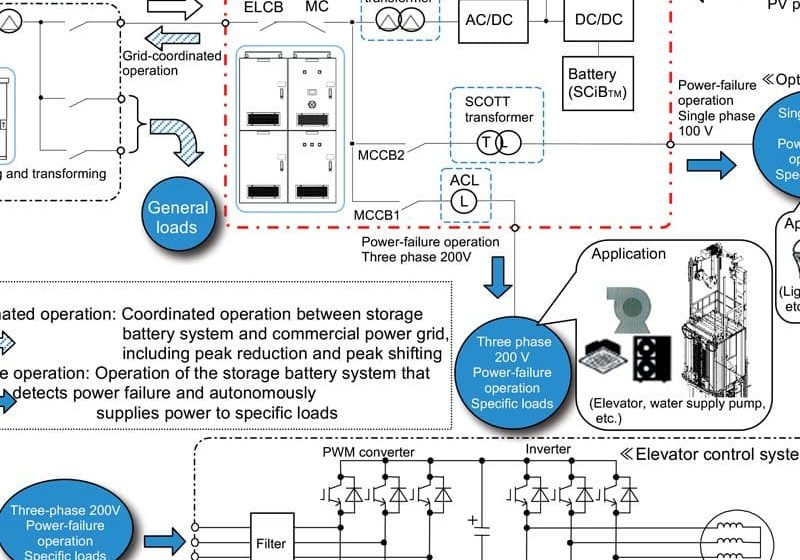

The Tauern Autobahn (A10) is an important north-south connection in the Alps region of Austria. Approximately 6,500 m long, the Tauern Tunnel is located on the A10 between 80.9 and 87.4 km. The tunnel tubes are equipped with full cross ventilation, and each tube is divided into four ventilation zones. Air handling units are located at the north and south portals, as well as in a cavern between the tubes at the tunnel’s approximate halfway point.

The cavern is connected to a 600-m-long vertical shaft into open air. At the top of the shaft, the air flows through ventilation ducts. The shaft air is divided through a wall into supply and exhaust sections. The shaft has a diameter of approximately 10 m. Approximately one-third of the cross-sectional area is used for exhaust air, with the remainder used for fresh air. Alimak rack-and-pinion elevators for personnel transport are installed on the divider wall in both the air-supply and -exhaust shafts.

A Unique Task

Both Alimak elevators have been performing their specific roles here since 1975. Built into the ventilation shaft, the elevators serve a platform that facilitates inspection of the shaft walls. When not in use, the steel platform is used as a shaft cover. Passage openings for the Alimak elevators make it possible to operate the platform vertically using a hoisting system comprised of winches, crane girders and deflection rollers.

One of the elevators has a single landing above the platform at the top of the shaft, which serves both as its base and rest station when not in use. The other elevator also has a landing at the top of the shaft. Its base/rest position is situated approximately 10 m above the base of the shaft in a recess of the cavern. Here, the elevator moves horizontally by means of a horizontal carriage. The cage thereby reaches the mast, to which it is automatically docked. Electrically operated winches serve as cable feeders, with transformers regulating power supply.

Time for an Upgrade

After many years of use, both Alimak elevators were due for refurbishment. Because of their special configuration, new elevator cages could not be installed easily. Therefore, the elevators, cable winch necessary for operation, horizontal carriage, electrical control cabinets and transformers were removed from the premises and refurbished. The entity responsible for the Tauern Tunnel, Autobahnen-und Schnellstraßen-Finanzierungs-Aktiengesellschaft, and Alimak Hek coordinated the process to minimize traffic interruption.

Work primarily took place during the early autumn months, which are when the A10 is least busy. Workers dismantled elevator cages, electrical cabinets and winches. Using chain hoists, muscle, precision and a special loading crane, these parts were brought through the top of the shaft into open air. Specially constructed equipment was also used at the bottom of the shaft to disassemble the horizontal carriage, winch and electrical cabinets. A HEK MSM Super mast-climbing work platform transported the equipment from the recess to the shaft base.

Comprehensive Refurbishment

Following loading and transport, a complete refurbishment was carried out in the ISO-certified Alimak Hek production facility in Skellefteå, Sweden. After structural and electrical engineering tests, all components still usable were cleaned, sandblasted, resealed and freshly painted. In addition to the Alimak components, the access stairs and railing in the recess of the supply air lift were cleaned, and the protective housing for the horizontal carriage was refurbished.

Completely refurbished and fitted with new safety devices, gears and motors, the components began their journey back to their place of origin. Thanks to the experience gained during the disassembly and with the help of the Alimak Hek equipment, the elevators resumed service after successful installation.

Get more of Elevator World. Sign up for our free e-newsletter.