Choosing an additional certification procedure based on ASME A17.7/CSA B44.7 can allow companies to deviate from the stipulations under ASME A17.1/CSA B44.

Lift manufacturers increasingly choose an additional certification procedure based on ASME A17.7/CSA B44.7. Using this North American standard for the design and construction of lifts allows both North American and European companies to deviate from the stipulations under ASME A17.1/CSA B44, provided a risk evaluation will demonstrate safety issues are not compromised in any way. Robert Kaspersma, senior specialist at Liftinstituut, explains:

“In that way, the North American approach gets closer and closer to the earlier established European approach in accordance with the Lift Directive. In that part of the world, conducting a risk evaluation and taking measures are also part of product design and certification. That is for cases in which the design deviates from the harmonized lift standards EN 81-1 and EN 81-2. However, this way of working is not unique for the lift industry. In other business sectors, this has been the most common thing to do for years, also in North America.”

For European manufacturers wishing to operate in the North American market, A17.7 can be a great help to launch their products faster. The A17.7 process will often see the launch of a product within six months, in contrast with the usual four to five years’ wait. However, Kaspersma strongly recommends manufacturers choosing this option do their due diligence before they make any alterations to their products and create a paper war in the process. According to Kaspersma, “That is because the North American and European markets are quite different. You hold back from any next steps until you are absolutely sure there is a need for your product.” For any next steps, Kaspersma emphasizes A17.7 “only” refers to the technical requirements for lifts and escalators:

“In addition, lifts and escalators must comply with the national building codes under U.S. and Canadian law. The same goes for electrical codes in both countries. Certain fire regulations must also be followed; these regulations may vary from one state to another. All calculations must be provided in accordance with the North American methodologies. Proper preparation will make or break the business.”

Another possible rock in the road is the often-critical attitude of U.S. AHJs. Dennis Lindeboom, international account manager at Liftinstituut, explains AHJs are ultimately responsible for admitting products after certification, and they sometimes come up with additional notes. Lindeboom said:

“Fortunately, we notice a growing trend of [AHJs] accepting A17.7 and the corresponding certification procedures. The fact that an objective third party like Liftinstituut is involved [often] gives them great joy, since it allows them to share their responsibility.”

Lindeboom indicates the opportunities A17.7 offers to manufacturers in North America. By being able to deviate from A17.1, manufacturers can be more innovative; for instance, in the area of buffers. Lindeboom explains:

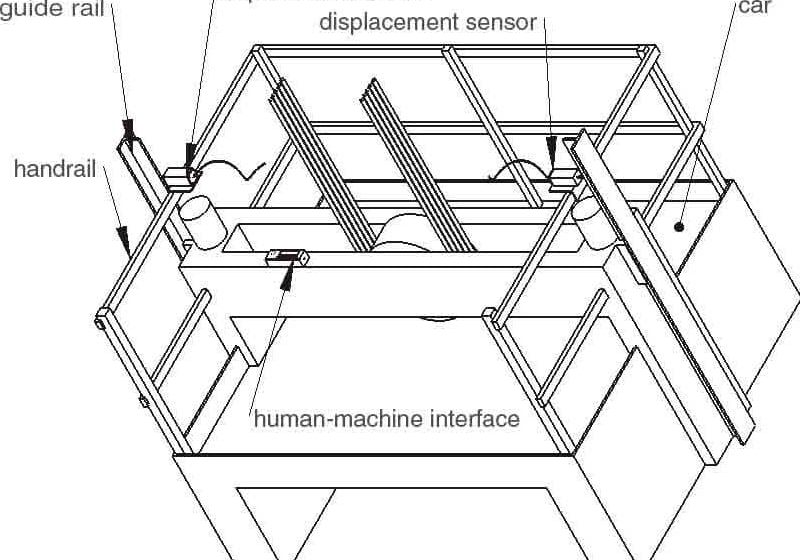

“Based on A17.7, it is possible to use polyurethane buffers instead of the usual steel springs and hydraulic buffers as described in A17.1. The advantage of these alternative buffers is that they can be much more compact. The elevator well can, therefore, be somewhat shallower. In addition, polyurethane buffers cannot rust.”

Lindeboom also sees advantages for manufacturers in Europe. He explains that in the past, it was difficult for manufacturers to gain access to the North American market with their existing products, as they were not allowed to deviate from A17.1. Now, deviations are allowed, as long as they are in accordance with A17.7, the safety level is equivalent or higher and this fact is underpinned by a risk analysis. As an example, he mentions a vacuum lift, which has been introduced in North America:

“As this type of lift is not suspended on suspension ropes and vacuum is the actual means of support, it is impossible to meet A17.1. If the equivalence of the safety level is underpinned by a risk analysis, and this has been confirmed by an Accredited Elevator/Escalator Certification Organization (AECO) after a stringent inspection (based on A17.7), the path is free for approval by the local authorities in the individual states in North America.”

Working with A17.7 also offers good opportunities for North American manufacturers seeking to expand to the European market, leading to more affiliation of their products with the European Lift Directive. As examples of recently Communauté Européenne-certified North American lift manufacturers by Liftinstituut, Lindeboom mentions The Peelle Co., Hollister-Whitney Elevator Corp. and Wurtec, Inc. “Their positive reactions prove their enthusiasm in terms of certification by Liftinstituut, making the associated capital expenditure certainly their money’s worth,” he said.

Lindeboom comments about the added value from Liftinstituut for both European and North American manufacturers:

“In Europe, we gained much experience in practicing performance-based safety, together with the associated risk evaluations. We now also use this experience worldwide, like in North America. In regard to North America, we are the only AECO fully dedicated to evaluating and certifying lifts and escalators. So we know all the ins and outs of these products, as well as the issues involved.”

Get more of Elevator World. Sign up for our free e-newsletter.