Advantages and Disadvantages of Hydraulic Lifts

Jun 2, 2022

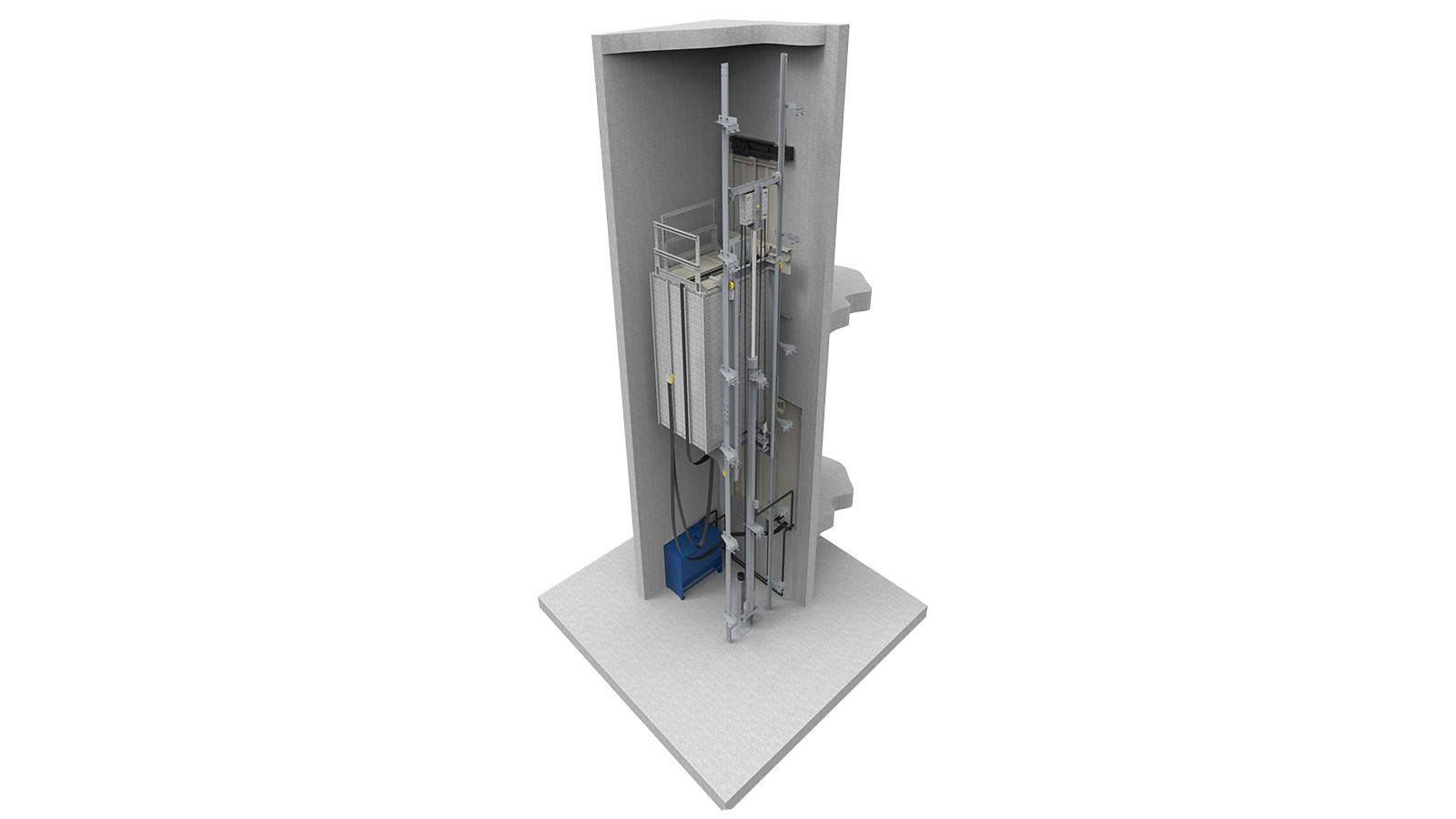

Hydraulic lifts have been used as vertical-transportation (VT) element for a long time. Hydraulic machines use liquid fluid power to perform work as it moves in proportion with the flow and have different designs. On the other hand, hydraulic lifts are not preferred by many building owners, or they are approached with suspicion. Additionally, many global manufacturers stopped making hydraulic lifts. However, principally, based on fields and place of usage, hydraulic lifts may be more advantageous than electric lifts.

Hydraulic lifts also save place. As counterweights are not used, they save place between 10% and 20%, compared to electric lifts with the same capacity. Their machine rooms do not have to be on the well; they may be at the lowest floor and even under the pit. Therefore, their placement is more flexible. Pit and last floor distances are smaller than the electric lift. So, they are ideal for old buildings with less space.

In hydraulic lifts, the elevator’s load is carried by the building base, while in the machine room traction lift system, the load is carried by the floor. In old buildings, the building base may not be sufficient for the load of heavy lifts.

Car areas of hydraulic lifts may be bigger than the traction lift cabin with the same capacity, because maximum car area for hydraulic lifts and traction lifts are different, according to EN 81-20. For example, maximum car area of a traction elevator with a capacity of 1,600 kg is 3.56 m2, while it is 5.04 m2 for a hydraulic lift with the same capacity. Therefore, hydraulic lifts are better for carrying huge objects like cars, transformers or cases.

The maintenance of hydraulic lifts is easier, compared to electric lifts. As the number of moving parts is less, the number of parts that wear off are also less. So, modernization costs are also low. For example, hydraulic lifts do not have mechanical components like traction sheave and ropes. Their control module is simpler than those in traction lifts. The number of electronic cards is less. As they do not require various components like expensive power cards, inverter modules and circuit breakers, the budget that will be spent for electrical components, which have the largest share in modernization expenses, is lower, while the time needed for modernization is longer. As long as the control mechanisms of the valve block are regularly maintained, their lifespan is long. They have a user-friendly interface as they mainly require mechanical controls. As the control system is simple, various maintenance companies may carry out correct maintenance. Thus, considering elevators with a relatively complex control system, such as Mitsubishi, there is a wide range of company options and price scales in terms of carrying out maintenance activities for hydraulic lifts.

Their initial investment cost is lower. High-tonnage traction lifts are special productions for global manufacturers. Therefore, their prices are higher compared with hydraulic lifts of the same capacity. For the buildings up to three floors, hydraulics lifts will be cheaper.

Except the rooms adjacent to the machine room, the noise level inside the cabin and around the shaft is lower. The number of sources that create noise is small, except the folding cylinder block and the cabin moving on the rails.

They are safer. The is no risk of acceleration if they are designed in line with the standards. The slow fluid flow of hydraulic cylinder does not allow acceleration. Even when the hydraulic fluid comes out of a broken or cracked pipe, which is the biggest risk, various types of flow control valve types are closed, and the fluid gets retained in the cylinder. Thus, cabin does not fall down. Rescuing passengers is also easier, compared to traction lifts. The emergency valve is simply opened when the cabin is not moving, even in case of power outage. The fluid in the cylinder runs to the boiler, and the cabin descends slowly. Considering some traction lifts use wiring even for activating the engine brakes, hydraulic lifts offer a safer evacuation. In seismic zones, hydraulic lifts are again safer. As there is no counterweight, there is no risk of derailment of counterweight during an earthquake

The reasons why hydraulic lifts are not preferred can be listed as below:

- They are slow. Their maximum speed is 1 m/s, while their speed is generally 0.25 m/s to 0.63 m/s. Therefore, they are not convenient for high traffic.

- The hydraulic fluid, which opens and closes the cylinder, varies with the temperature. As the fluidity of the oil varies due to fluctuating temperature, oil can leak out, or unstable motion may occur. Traction lifts are more resistant, temperature changes.

- Oil leakage has negative impacts on the system. Oil leakage is the result of fluid bypassing a piston seal either through a worn seal or a worn cylinder. As a result, the cabin may slip down or more oil should be added to the boiler. A worn cylinder cannot be repaired. It should be replaced, but as a replacement requiring a costly and skillful process.

- Installation and operation require competence. Today, global manufacturers work on decreasing the time and skill needed for elevator installation. However, a decrease in these parameters may cause non-functional installation. Maintenance also requires expertise and experience. Adjustment and maintenance of hydraulic components, like valve block, valves, cylinder and pipe, should be carried out by qualified staff.

- Their energy efficiency is lower. Required motor power for the same capacity can be twice the traction lift. Although energy is not spent when the cabin moves down, a higher energy is needed when the cabin moves up, even if the cabin is empty, as there is no counterweight.

- Their travel distance is limited. Ideally, they are used for distances up to 18 m, but a travel distance of 30 m is possible with one piston, while a travel distance of 40 m is possible with double pistons. Travel distance is proportional to the cylinder lengths.

Although they have some disadvantages, hydraulic lifts are still more efficient in various places. Their biggest advantage is their strong design and simple components. As much as the building owners and designer know more about this type of lifts, they will be preferred more often.

Also read: Maintenance, the Correct Approach to Raise the Quality

Get more of Elevator World. Sign up for our free e-newsletter.